Aluminum Siding 4x8 Sheets - Aluminum Extrusion/Profiles for Doors SAD4-404-5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Extrusion/Profiles for Doors SAD4-404-5 Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Extrusion/Profiles for Doors SAD4-404-5:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

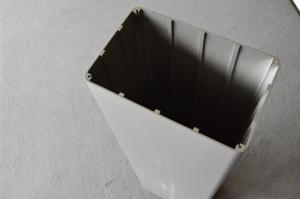

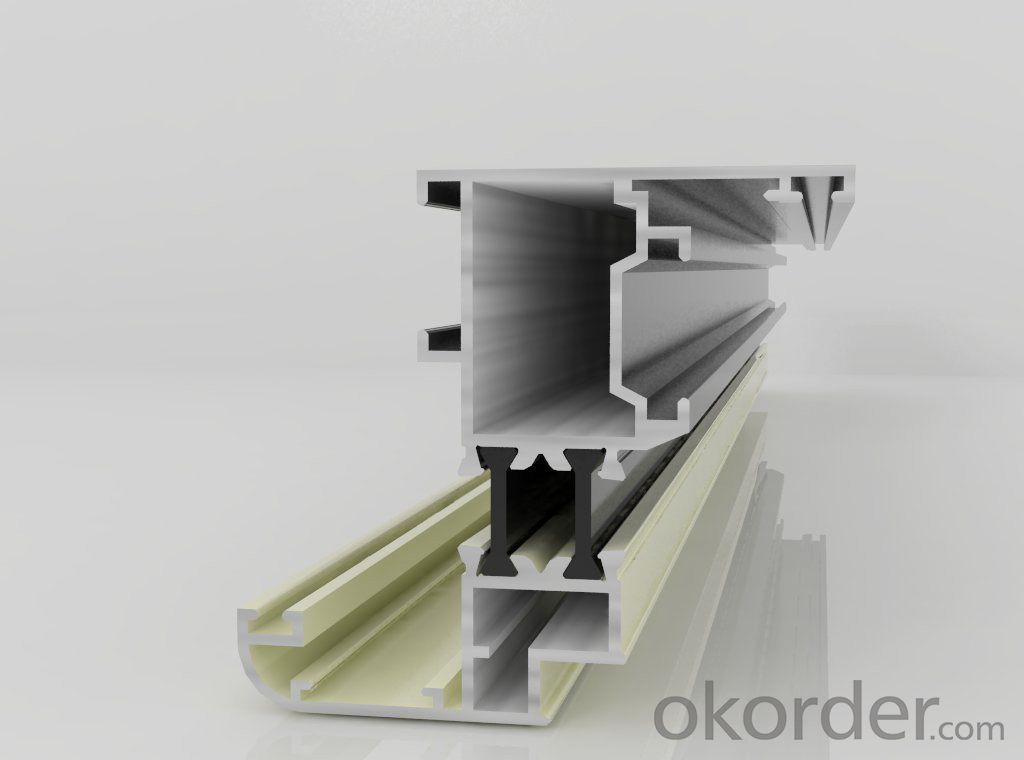

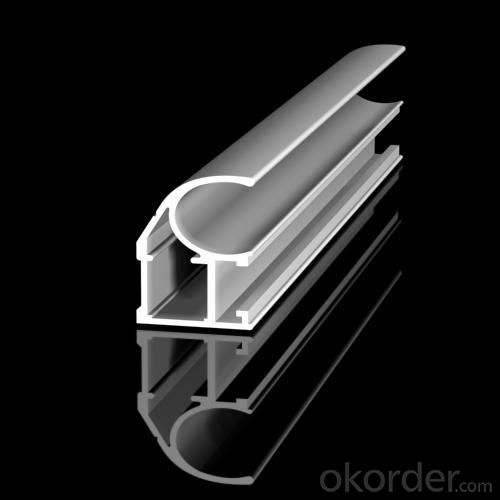

3.Aluminum Extrusion/Profiles for Doors SAD4-404-5 Images:

4.Aluminum Extrusion/Profiles for Doors SAD4-404-5Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

① How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can aluminum sheets be custom cut to specific dimensions?

- Certainly! Custom cutting aluminum sheets to specific dimensions is absolutely possible. Aluminum is a highly versatile material that lends itself easily to cutting and shaping using a wide array of tools and techniques. This remarkable adaptability enables precise customization to fulfill specific requirements and measurements. Whether for industrial, commercial, or residential purposes, aluminum sheets can be expertly cut to desired sizes, guaranteeing a flawless fit and optimal functionality. Furthermore, the ability to custom cut aluminum sheets allows for unparalleled design flexibility, resulting in the creation of distinctive and tailor-made solutions.

- Q: Can someone please help me with the resonance structure for AlCl3. When I draw it, the central Al does not have a complete octet. I read that this is usually the case for atoms like Boron and Aluminium who only have three valence electrons. Is this correct? Also, as a follow on question, does AlCl3 display resonance?

- Since aluminum only has 3 valence electrons it will be missing two electrons from its octet. This means that one of the chloride groups must share an extra electron group with the aluminum. Any three of the chlorides can share an extra electron pair with it (i.e. they'll have 2 lines attached to aluminum), so there is resonance. There are 3 to be specific, one for each chloride sharing another electron pair with Al.

- Q: This question asks for a comparison of the positive and negative aspects of utilizing aluminum sheets in various applications.

- <p>Advantages of using aluminum sheets include their lightweight nature, which reduces transportation and handling costs. They are also corrosion-resistant, making them suitable for outdoor applications. Aluminum sheets are recyclable and environmentally friendly, with a high recycled content rate. They are also easy to fabricate and can be cut, bent, and shaped into various forms. Disadvantages include lower strength compared to steel, which may require thicker sheets for certain applications. They can also be more expensive than some other materials, and their light reflection can sometimes be a concern in certain environments.</p>

- Q: What is the coefficient of expansion for aluminum sheets?

- The coefficient of expansion for aluminum sheets is roughly 0.000022 per degree Celsius, indicating that the aluminum sheet will expand by 0.000022 times its original length with every degree Celsius rise in temperature. It is crucial to take this coefficient of expansion into account in situations where the aluminum sheets may encounter fluctuating temperatures, as it can impact the material's overall dimensions and stability.

- Q: Are aluminum sheets suitable for insulation cladding?

- Yes, aluminum sheets are suitable for insulation cladding. Aluminum is a highly versatile and durable material that is commonly used in construction for various purposes, including insulation cladding. Aluminum sheets have excellent thermal properties, making them an effective barrier against heat transfer. They also have a low thermal conductivity, which means they can prevent the transfer of heat between the interior and exterior of a building, resulting in improved energy efficiency. Furthermore, aluminum is lightweight and easy to handle, which makes it convenient for installation purposes. It is also resistant to corrosion, making it a long-lasting option that can withstand various weather conditions. Additionally, aluminum sheets are available in different thicknesses, allowing for customization based on specific insulation requirements. In terms of aesthetics, aluminum sheets offer a sleek and modern appearance, enhancing the overall look of the building. They can be easily painted or coated in various colors to match the desired aesthetic design. Overall, aluminum sheets are an excellent choice for insulation cladding due to their thermal properties, durability, ease of installation, and aesthetic appeal.

- Q: Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum, making it thicker and more durable. This process can be customized to achieve various finishes such as clear, colored, or even textured surfaces. The type of finish depends on factors like the alloy composition, anodizing method, and the desired appearance. Anodized aluminum sheets are widely used in various industries including architecture, automotive, and electronics due to their corrosion resistance, aesthetic appeal, and ability to retain color over time.

- Q: Aluminum plate 90 degree bending, why cracking?

- There are several reasons why the 180 degree bending of aluminum plate causes cracking: 1. The bending edge is parallel to the rolling direction of the aluminum plate, so it is easy to crack and turn the bending direction to 90 degrees. 2. 180 degrees bending angle is too much to be greater than the minimum

- Q: Are aluminum sheets resistant to vibration?

- Yes, aluminum sheets are generally resistant to vibration due to their inherent strength and durability. The high stiffness-to-weight ratio of aluminum, along with its ability to dampen vibrations, makes it an ideal material for applications requiring vibration resistance.

- Q: Can aluminum sheets be painted?

- Yes, aluminum sheets can be painted. However, it is important to properly prepare the surface by cleaning, sanding, and using a primer specifically formulated for metal surfaces to ensure good adhesion of the paint.

- Q: What is the weight of aluminum sheets?

- The weight of aluminum sheets can vary depending on the thickness and dimensions of the sheet. As a general guideline, the weight of aluminum sheets can range from about 2.7 grams per square centimeter (g/cm^2) for thin sheets to around 6.9 g/cm^2 for thicker sheets. However, it is important to note that these values are approximate and can vary slightly depending on the specific alloy and manufacturing process used. Therefore, it is recommended to consult the manufacturer or supplier for precise weight specifications for a particular aluminum sheet.

Send your message to us

Aluminum Siding 4x8 Sheets - Aluminum Extrusion/Profiles for Doors SAD4-404-5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords