Aluminum Coils/Sheets - PE/PVDF Color Coated Aluminum Coil for Shutter Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of PE/PVDF Color Coated Aluminum Coil for Shutter Decoration

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of PE/PVDF Color Coated Aluminum Coil for Shutter Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PE/PVDF Color Coated Aluminum Coil for Shutter Decoration

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

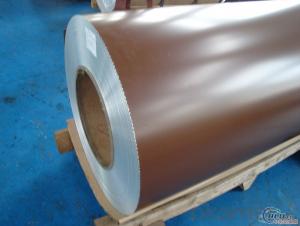

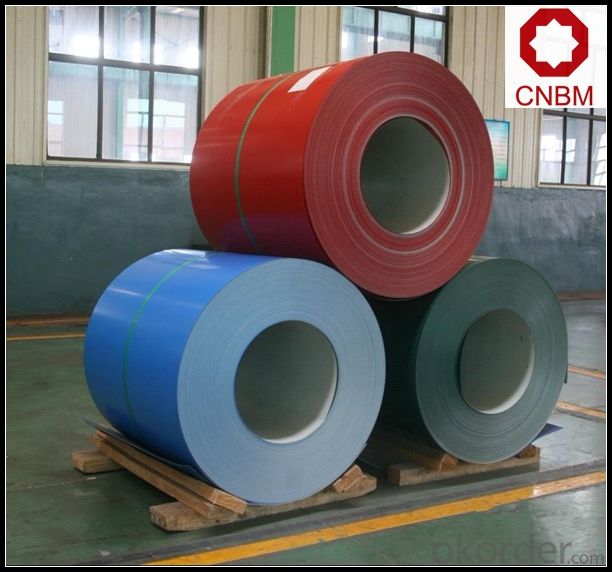

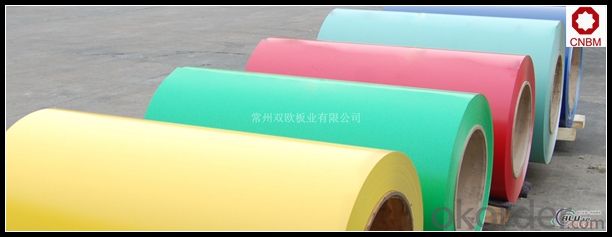

5. Image of PE/PVDF Color Coated Aluminum Coil for Shutter Decoration

6. Package and shipping of PE/PVDF Color Coated Aluminum Coil for Shutter Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

"Aluminum roll rolling machine after rolling, corner after processing, metal products for flying shears.Aluminium coil are widely used in electronics, packaging, construction, machinery, etc., more aluminum volume production enterprises in China, production technology has catch up with the developed countries, according to the aluminum volume contains metal elements, aluminum volume probably can be divided into nine categories, respectively is 1000 series 1000 series, 2000 series aluminum plate, aluminum plate, 4000 series aluminum, 5000 series, 6000 series, 7000 series, 8000 series, 9000 series.Silicon have a corrosion effect on carbide.Although generally called more than 12% Si aluminum alloy high silicon aluminum alloy, it is recommended to use diamond tool, but this is not absolute, increasing silicon content on the destructive force of the cutting tool is gradually increasing.So some vendors in silica content more than 8% when diamond tool is recommended.

"

- Q: What is the difference between aluminum coils and aluminum sheets?

- Aluminum coils and aluminum sheets are both made from the same material, which is aluminum. However, there are some key differences between the two. One major difference is their form and shape. Aluminum coils are typically long, continuous pieces of aluminum that are wound into a coil shape. They are often used in industries such as construction, automotive, and HVAC for applications such as roofing, insulation, and air conditioning systems. On the other hand, aluminum sheets are flat pieces of aluminum that come in various sizes and thicknesses. They are commonly used in industries like aerospace, transportation, and packaging for applications such as aircraft parts, automotive body panels, and food packaging. Another difference is their manufacturing process. Aluminum coils are produced by a process called continuous casting, where molten aluminum is continuously poured into a mold and then cooled and solidified into a coil shape. This process allows for the production of long, continuous coils. Aluminum sheets, on the other hand, are typically produced through a rolling process. The aluminum is passed through a series of rollers that progressively reduce its thickness until the desired sheet thickness is achieved. This process allows for the production of flat sheets with specific thicknesses. Furthermore, the uses and applications of aluminum coils and sheets also differ. Due to their coil shape, aluminum coils are commonly used in applications that require long continuous lengths, such as roofing or HVAC systems. Aluminum sheets, with their flat shape, are often used in applications where a flat surface is needed, such as in the manufacturing of panels or components. In summary, the main difference between aluminum coils and aluminum sheets lies in their form, manufacturing process, and applications. Coils are long, continuous pieces of aluminum produced through continuous casting, while sheets are flat pieces produced through rolling. The choice between coils and sheets depends on the specific requirements of the application.

- Q: Which type of wheel is more durable, long-lasting and which wheel type would cost more, Aluminum or chrome?

- Aluminum are lighter, which mean faster car. Stronger, stay cleaner longer. Chrome are more expensive. Just made for people who like being flashy.

- Q: This question asks for an explanation of the distinctions among various grades of hot rolled aluminum coils, focusing on their characteristics and applications.

- <p>Different grades of hot rolled aluminum coils are distinguished by their chemical composition, mechanical properties, and applications. Grades like 1000 series are pure aluminum with high ductility and electrical conductivity, suitable for general purposes. 3000 series, with added manganese, offer moderate strength and are used in cooking utensils and chemical equipment. 5000 series, containing magnesium, are strong and corrosion-resistant, used in marine applications and aerospace. 6000 series, with silicon and magnesium, are known for their mechanical strength and are used in construction and automotive parts. Each grade has specific alloying elements that tailor its properties for different industrial needs.</p>

- Q: Are aluminum coils suitable for air conditioning systems?

- Air conditioning systems can utilize aluminum coils, which are commonly employed due to their numerous advantages. Firstly, aluminum, being a lightweight material, facilitates ease of handling and transportation during installation. Additionally, this lightweight characteristic reduces the unit's overall weight, rendering it more energy-efficient. Moreover, aluminum coils possess exceptional heat transfer properties, thereby enabling efficient air cooling. They exhibit enhanced thermal conductivity, facilitating rapid and effective heat transfer. Consequently, this leads to improved cooling performance and enhanced energy efficiency, resulting in reduced electricity consumption and long-term cost savings. Furthermore, aluminum coils surpass other materials, such as copper, in terms of superior corrosion resistance. Given the exposure of air conditioning systems to moisture and humidity, this resistance is crucial. Aluminum coils can withstand these conditions without corroding or deteriorating, ensuring a longer lifespan and reliable performance. Another advantage of aluminum coils lies in their affordability. Aluminum is a cost-effective material, making it a favored choice among air conditioning manufacturers. This affordability subsequently translates into lower costs for consumers, making air conditioning systems more accessible and economically viable. In conclusion, the suitability of aluminum coils for air conditioning systems is evident due to their lightweight nature, impressive heat transfer properties, corrosion resistance, and affordability. They offer efficient cooling capabilities, durability, and cost-effectiveness, establishing themselves as the preferred choice for air conditioning units.

- Q: How do aluminum coils contribute to energy-efficient HVAC systems?

- The role of aluminum coils in making HVAC systems energy-efficient is crucial. Firstly, aluminum is an exceptional heat conductor, enabling efficient heat transfer between different areas. In HVAC systems, aluminum coils are utilized in the condenser and evaporator units to facilitate the heat exchange process. In the condenser unit, the hot refrigerant vapor from the compressor passes through the aluminum coils. Due to the coils' high thermal conductivity, the heat is rapidly dissipated to the surrounding air, allowing the refrigerant to condense and release the heat energy. This effective heat transfer enhances the cooling performance of the HVAC system. Similarly, in the evaporator unit, the aluminum coils are responsible for absorbing heat from the indoor air. The cold refrigerant inside the coils absorbs the heat, resulting in the air cooling down. Ultimately, the cooled air is circulated back into the room. The superior thermal conductivity of aluminum enables quick heat absorption, improving the overall cooling efficiency of the HVAC system. Moreover, aluminum coils offer an energy-saving advantage by being lightweight. Compared to traditional copper coils, aluminum coils reduce the overall weight of the HVAC system. This weight reduction leads to lower energy consumption by the system's fan and compressor, as they require less effort to move the air and refrigerant throughout the system. Additionally, aluminum coils are highly resistant to corrosion, which prolongs the lifespan of the HVAC system. Corrosion can hinder heat transfer efficiency and result in refrigerant leaks, causing the system to consume more energy. By utilizing aluminum coils, the risk of corrosion is minimized, ensuring long-term energy efficiency. In conclusion, aluminum coils enhance the energy efficiency of HVAC systems by improving heat transfer efficiency, reducing overall system weight, and providing corrosion resistance. These factors collectively contribute to the effective operation of HVAC systems, consuming less energy while maintaining optimal indoor comfort.

- Q: What are the different coil pattern options for aluminum coils?

- There are several different coil pattern options available for aluminum coils, depending on the specific application and desired aesthetic. Some common coil pattern options include: 1. Stucco Pattern: This pattern features a textured, raised surface that resembles the appearance of stucco. It provides increased durability and a non-slip surface, making it suitable for applications such as flooring or outdoor surfaces. 2. Diamond Pattern: This pattern consists of small diamond-shaped embossed designs, providing a visually appealing and slip-resistant surface. It is commonly used in applications such as stair treads, walkways, and decorative panels. 3. Wood Grain Pattern: This pattern replicates the appearance of natural wood grain, making it an attractive option for various architectural and interior design purposes. It is often used in applications such as wall cladding, ceiling panels, and furniture. 4. Checkered Pattern: Also known as the checker plate pattern, it features a grid of raised diamonds or squares. This pattern offers excellent slip resistance and is commonly used in applications where safety is a priority, such as ramps, industrial flooring, and staircases. 5. Plain Smooth Pattern: This pattern has a smooth, flat surface without any embossed designs or patterns. It is a versatile option suitable for a wide range of applications, including roofing, gutters, and general fabrication. 6. Ribbed Pattern: This pattern consists of parallel lines or ribs running along the length of the coil. It provides added strength and rigidity, making it commonly used in applications such as truck bodies, trailers, and industrial equipment. These are just a few examples of the various coil pattern options available for aluminum coils. The choice of pattern ultimately depends on the specific requirements of the project, such as functionality, durability, and aesthetic preferences.

- Q: This question asks about the current market demand for aluminum coil, which is a versatile material used in various industries.

- <p>The market demand for aluminum coil is significant and growing due to its wide range of applications across industries such as construction, automotive, aerospace, packaging, and electronics. Its lightweight, corrosion resistance, and recyclability make it a preferred material for many applications. The demand is influenced by economic growth, technological advancements, and sustainability initiatives. As countries focus on greener construction and manufacturing processes, the demand for aluminum coil is expected to increase further.</p>

- Q: Are aluminum coils recyclable?

- Yes, aluminum coils are recyclable. Aluminum is one of the most recyclable materials, and it can be recycled indefinitely without losing its quality. The recycling process of aluminum coils involves melting them down to form new coils or other aluminum products. This not only reduces the amount of waste in landfills but also saves energy and resources required to produce new aluminum from raw materials. Recycling aluminum coils is an environmentally friendly choice that helps conserve natural resources and reduce greenhouse gas emissions.

- Q: Are aluminum coils suitable for curtain wall systems?

- Yes, aluminum coils are highly suitable for curtain wall systems. Aluminum is a lightweight and durable material that offers numerous benefits for curtain wall applications. Firstly, aluminum coils are corrosion-resistant, ensuring the longevity and durability of the curtain wall system. This makes them ideal for exterior applications where the system is exposed to various weather conditions. Additionally, aluminum does not rust, which is a significant advantage over other materials like steel. Furthermore, aluminum coils can be easily extruded into various shapes and sizes, allowing for flexibility and creativity in curtain wall design. This enables architects and designers to create visually appealing and unique structures. Moreover, aluminum is a highly sustainable material. It is 100% recyclable, which means that it can be reused without any loss in quality. This makes aluminum coils an eco-friendly choice for curtain wall systems, aligning with the growing demand for sustainable building materials. Additionally, aluminum is a good conductor of heat and electricity, which can contribute to energy efficiency in curtain wall systems. By using thermal breaks and incorporating insulation, aluminum curtain walls can effectively regulate temperature and reduce energy consumption, leading to cost savings in the long run. Overall, aluminum coils are an excellent choice for curtain wall systems due to their corrosion resistance, versatility, sustainability, and energy efficiency.

- Q: I have completely disassembled my aluminum bass boat and it is being sandblasted.I am restoring the boat and will be giving it a new paint job.What do you recommend in the way of primer,paint or anything else I need to know.I just don,t want to mess it up by using the wrong thing.Best answer gets a fishing trip in the same boat we are talking about. If you can make it here I will put you on some fish.Catfish,bream,crappie,bass or even saltwater fish.

- Contact the manufacture and see what they used as it held up for quite a few yrs. Primer for aluminum is the beginning.

Send your message to us

Aluminum Coils/Sheets - PE/PVDF Color Coated Aluminum Coil for Shutter Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords