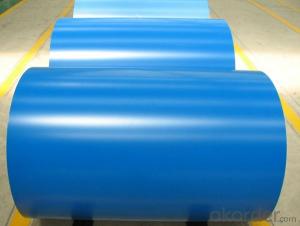

Self-Adhesive Aluminum Foil Sheets - Color Coated Aluminum Coil with 0.018 to 0.50mm (PE/PVDF)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Pattern: orange peel, aluminum sheet5 bar,half a ball,diamond,compass shape

1.Orange peel aluminum sheet/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052

2)Temper :0 H114 H24 H32

3) Specification thickness:0.2mm-3.0mm

width:50mm-1300mm

Length: according your request

4)Application: Refrigeration. Air-conditioner. keep warm well such as pipe ,tank

5)Surface: No crack,canker, hole

2. aluminum sheet5 bar/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

3.Compass shape aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: thickness:1.0mm-10mm

width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

4.Diamond aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: building industry,packing,decorative

5)Surface: No crack,canker, hole

4) Delivery time: 15-20 days after confirming order.

For all above:

1) Minimum order quantity: 5 tons per size.

2) The term of payment: T/T, irrevocable L/C at sight.

3) Packing: Export standard, waterproof wooden,craft,plywood pallet,etc.

- Q: Can aluminum sheets be utilized as a material for constructing caravan roofs?

- <p>Yes, aluminum sheets can be used for caravan roofs. They are lightweight, durable, and resistant to corrosion, making them an ideal material for this purpose. Aluminum sheets are easy to install and maintain, and they can also reflect heat, helping to keep the interior of the caravan cooler. However, it's important to ensure that the aluminum sheets are of good quality and properly sealed to prevent water ingress and to maintain structural integrity over time.</p>

- Q: Can aluminum plate resist acid and alkali?

- The metal oxide film changes the surface state and properties, such as surface coloring, corrosion resistance, abrasion resistance and hardness, and metal surface protection. For example, aluminum anodizing, the aluminum alloy placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, under certain conditions and applied electricity under the electrolysis. Anodized aluminum or its alloy, formed on the surface of alumina thin layer, its thickness is 5~20 microns, anodized aluminum or its alloy. Therefore, the surface hardness and wear resistance of the aluminum alloy were greatly improved by the treatment process.Shanghai Ai Li AI metal materials, dedicated to serve you.

- Q: What does exterior wall imitate aluminium paint have? Imitate aluminium plate paint is fluorocarbon paint?

- If not missing the cost or use aluminum plate, because the fluorine content of fluorocarbon metal paint paint factory production lot are not enough, so the warranty 10-15 years is just a pretext, and the construction of the technical requirements for workers is relatively high.

- Q: Are aluminum sheets suitable for electrical conductors?

- Yes, aluminum sheets are suitable for electrical conductors due to their high electrical conductivity, lightweight nature, and cost-effectiveness.

- Q: Are the aluminum sheets suitable for manufacturing automotive body panels?

- Yes, aluminum sheets are suitable for manufacturing automotive body panels. Aluminum is a lightweight yet strong material that offers several advantages for automotive applications. Its high strength-to-weight ratio allows for improved fuel efficiency and better overall performance of the vehicle. Aluminum also has excellent corrosion resistance, making it suitable for withstanding harsh environmental conditions. Additionally, it can be easily formed and manipulated, allowing for complex designs and shapes required for automotive body panels. These characteristics make aluminum sheets a popular choice in the automotive industry for manufacturing body panels.

- Q: Can the aluminum sheets be used for manufacturing power distribution systems?

- Yes, aluminum sheets can be used for manufacturing power distribution systems. Aluminum is a widely used material in the electrical industry due to its excellent conductivity, lightweight, and cost-effectiveness. It is commonly used for manufacturing busbars, which are the main component of power distribution systems. Aluminum sheets can be easily fabricated and formed into the desired shape for busbars, allowing for efficient power transmission and distribution. Additionally, aluminum has good corrosion resistance, making it suitable for outdoor applications. However, it is important to ensure that the aluminum sheets meet the required electrical and mechanical specifications for power distribution systems to ensure safe and reliable operation.

- Q: Are aluminum sheets suitable for medical equipment?

- Yes, aluminum sheets are suitable for medical equipment. Aluminum is a lightweight metal that offers excellent durability and corrosion resistance, making it a popular choice for medical equipment manufacturing. It is used in various medical devices such as surgical instruments, diagnostic equipment, and patient monitoring systems. Aluminum sheets are easy to shape and form, allowing for the fabrication of intricate medical equipment designs. Additionally, aluminum is non-toxic and non-magnetic, which are important properties in medical settings. Its ability to withstand sterilization processes such as autoclaving further enhances its suitability for medical equipment. Overall, aluminum sheets are a reliable and versatile material for the production of medical equipment.

- Q: Could ring-pull can be transformed as aluminum sheet?

- Ring-pull cans will be reused after recycle, there are parts of ring-pull cans be transformed as aluminum sheet.

- Q: What are the different cutting tools used for aluminum sheets?

- Aluminum sheets can be cut using various cutting tools available. Here are some options: 1. Circular Saw: To achieve a clean and smooth cut, it is essential to employ a circular saw with a carbide-tipped blade featuring fine teeth. 2. Jigsaw: For intricate cuts and curves, a jigsaw equipped with a metal-cutting blade is a suitable tool to cut aluminum sheets. 3. Bandsaw: When dealing with larger or thicker sheets, a bandsaw with a fine-toothed blade can provide a precise and straight cut. 4. Shears: Electric or manual shears are effective for straight cuts and ensuring a clean finish while cutting aluminum sheets. 5. Plasma Cutter: Thicker aluminum materials can be efficiently cut using a plasma cutter, which employs high-temperature plasma to melt through the metal, resulting in precise cuts. 6. Laser Cutter: For precise and intricate cuts, laser cutting machines are commonly utilized. They produce a high-powered laser beam that melts and vaporizes the aluminum sheet, allowing for accurate cuts. Remember to prioritize safety by wearing appropriate gear such as gloves and goggles when using any of these cutting tools. The choice of the tool should depend on the thickness of the aluminum sheet and the desired cut. It is advisable to seek professional advice or consult the manufacturer's guidelines for the specific tool being used.

- Q: What is the color range available for aluminum sheets?

- Aluminum sheets come in a wide range of colors, offering a diverse selection. Standard colors include silver, black, white, bronze, and gold. Furthermore, aluminum sheets can be coated with different finishes, such as anodized, painted, or powder coated, which expands the color options even more. These coatings provide an array of colors, including vibrant shades like red, blue, green, yellow, and many others. Moreover, specialized processes enable the achievement of custom colors, allowing for personalized and unique choices. In summary, the color range for aluminum sheets is extensive and adaptable, meeting different aesthetic preferences and design needs.

Send your message to us

Self-Adhesive Aluminum Foil Sheets - Color Coated Aluminum Coil with 0.018 to 0.50mm (PE/PVDF)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords