Sublimation Aluminum Sheets Uk - Aluminium Coils for Color Coated PVDF 20-40 Microns

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

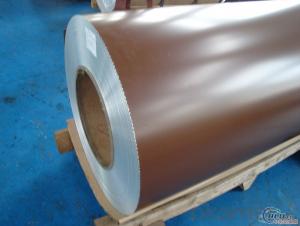

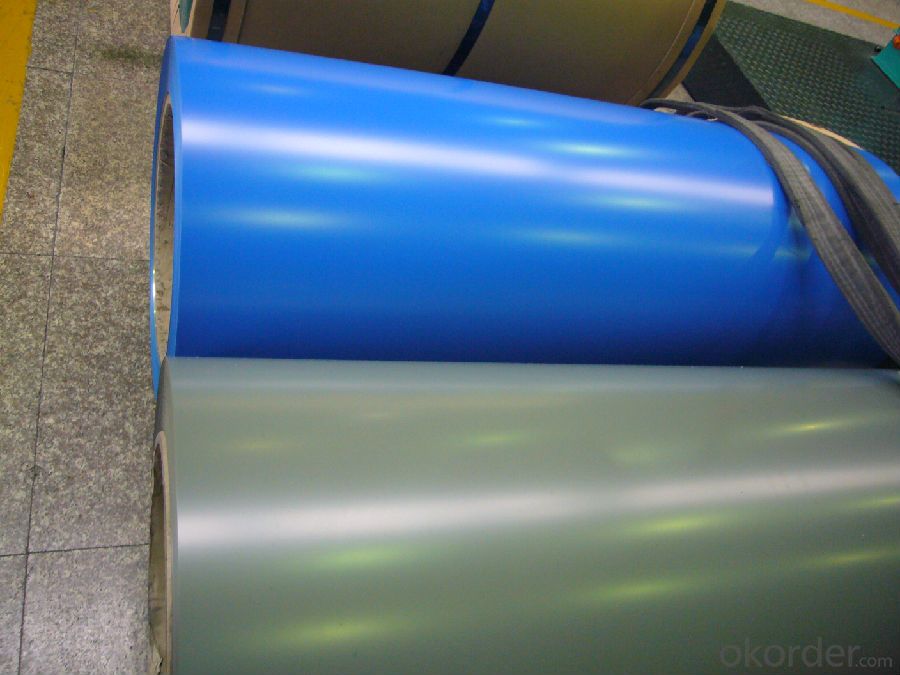

1.Structure of Aluminium Coils for Color Coated PVDF 20-40 microns

Aluminium Coils for Color Coated PVDF 20-40 microns is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Color Coated PVDF 20-40 microns

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Aluminium Coils for Color Coated PVDF 20-40 microns

4. Product Specification of Aluminium Coils for Color Coated PVDF 20-40 microns

| Alloy | Temper | Style | Thickness | Width |

| AA1100 | H14 | Direct Casting | 0.2mm-3mm | 1000mm-1500mm |

5.FAQ of Aluminium Coils for Color Coated PVDF 20-40 microns

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Is it possible to use aluminum sheets as a material for exterior wall cladding?

- <p>Yes, aluminum sheets are commonly used for exterior wall cladding due to their durability, low maintenance, and resistance to weather conditions. They are lightweight, easy to install, and can be recycled, making them an environmentally friendly option. Aluminum sheets can also be painted or coated in various colors and finishes, offering design flexibility. However, it's important to ensure proper installation and sealing to prevent water infiltration and to maintain the integrity of the cladding system.</p>

- Q: I recently had a new bridge plate and knobs made from aluminum for my guitar. They are bare uncoated aluminum. How would I go about protecting the parts from oxidation and corrosion? I just worry about the bridge plate because of sweat from playing my guitar near the bridge. There are no local places to get the parts chromed or anodized unfortunately.

- Aluminum gets a white coating of aluminum oxide and then does not further react with the air. You can put clear nail polish on the bridge and knobs.

- Q: Can aluminum sheets be an alternative to wood in certain applications?

- Yes, aluminum sheets can be an alternative to wood in certain applications. Aluminum sheets have several advantages over wood, including being lightweight, durable, and resistant to corrosion and fire. They can be used in various industries such as construction, automotive, aerospace, and marine, where wood may not be suitable due to its limitations. However, the selection of material depends on the specific requirements of the application and the desired properties needed.

- Q: Is the chemical formula for Aluminum Sulfate Al2(SO4)3?How and why is Al2(SO4)3 wrong?

- For the best answers, search on this site okorder

- Q: This question asks for methods to guarantee the safety and reliability of a project when using aluminum sheets.

- <p>To ensure your project's safety and reliability using aluminum sheets, follow these steps: 1. Choose high-quality aluminum sheets with the appropriate thickness and grade for your project's requirements. 2. Ensure proper design and engineering to withstand expected loads and stresses. 3. Use appropriate fasteners and joinery methods to secure the sheets, avoiding stress concentrations. 4. Implement corrosion protection measures such as coatings or anodizing, especially for outdoor applications. 5. Perform regular inspections and maintenance to check for signs of wear, corrosion, or damage. 6. Adhere to safety standards and regulations for aluminum construction. 7. Consult with professionals or engineers experienced in aluminum fabrication for guidance and validation.</p>

- Q: What are the common sizes of aluminum sheet?

- Common sizes of aluminum sheets vary depending on the specific requirements and industry applications. However, some standard sizes are commonly available in the market. These sizes typically range from 0.025 inches to 0.125 inches in thickness and can come in various widths and lengths. Some common width options include 36 inches, 48 inches, and 60 inches, while the length can range from 96 inches to 144 inches. Additionally, aluminum sheets can also be found in smaller sizes, such as 12 inches by 24 inches or 24 inches by 24 inches, which are often used for smaller projects or crafts. It is important to note that custom sizes can also be obtained through specialized aluminum sheet suppliers.

- Q: Is it feasible to recycle aluminum profiles after their use?

- <p>Yes, aluminum profiles can be easily recycled after use. Aluminum is one of the most recycled materials in the world due to its durability and recyclability. Recycling aluminum saves energy, as it requires only 5% of the energy needed to produce new aluminum from raw materials. The recycling process is straightforward, involving melting the aluminum, which can then be reformed into new products without losing its properties. This makes aluminum profiles an environmentally friendly choice for many applications.</p>

- Q: Aluminum standard 30*25*2500 to 1000 1 how to calculate the number of materials needed?. 2 how to calculate the cutting loss?

- The first is the volume slightly, the aluminum plate as a column volume V= length * width * height =1*2*0.001=0.002 cubic meters and then calculate the quality volume of m= V* density =0.002* density (see you for what kind of concrete, aluminum, aluminum, or Aluminum Alloy? If it's pure aluminum (if it's a high school physics title, or pure aluminum doesn't fit), it's 2700 kilograms per cubic meter.

- Q: How thick can aluminum sheets be?

- Aluminum sheets can vary in thickness, ranging from as thin as 0.006 inches (0.15mm) to as thick as 0.5 inches (12.7mm) or more, depending on the specific requirements and applications.

- Q: Can aluminum sheets be used for automotive heat shields?

- Indeed, automotive heat shields can utilize aluminum sheets. The automotive industry favors aluminum for its remarkable thermal conductivity and resistance to heat. With a high melting point, aluminum effectively disperses heat, safeguarding diverse components from excessive exposure. Furthermore, aluminum sheets are lightweight and malleable, enabling tailored designs to suit specific automotive purposes. Ultimately, aluminum sheets present a dependable and economical choice for automotive heat shields.

Send your message to us

Sublimation Aluminum Sheets Uk - Aluminium Coils for Color Coated PVDF 20-40 Microns

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords