Coated Aluminium Coil for Roofing Sheet/PE/PVDF Color Coated Aluminum Coil with God Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 1 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Aluminium Foil Description:

Aluminium Foil is structured by aluminium paper, which is the raw material .It is suitable for: Tobacco, food, beer, beverage, decoration, electric cable, electrolytic capacitor, medicine and air-conditioner.

2. Main Features of the Aluminium Foil:

High heat reflection & low thermal conductivity

Heat preservation & energy saving

Moisture barrier & waterproof

Low flammability

Strong, durable & corrosion resistance

Light weight & easy to install

Clean, safe and fibre free & no odour and toxicity, totally environmental-friendly

No mildew growth & no rodent and insect nesting

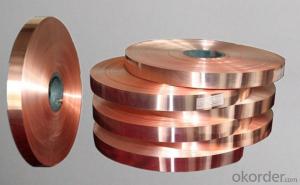

3. Aluminium Foil Images

4. Aluminium Foil Specification

1).thickness:0.022-1.2mm

2).coated thickness:18-25micron

3)..PE/PVDF coated

4).TemperaaO-H112.

5).1000 series aa1050 1060 1100

| Coated Aluminum Coils, Color Coated Aluminum Coils | |||||||

| Grade and Temper | Alloys: 1050, 1100, 3003,3005,3105, 5005,5052,8011,etc Temper: O H12 H14 H16 H18 H22 H24 H26 | ||||||

| Widths | 50-1500 mm available | ||||||

| Thickness | 0.022-1.2mm | ||||||

| Coil Specifications | I.D.: 405mm, 505mm O.D.: 800mm - 1270mm | ||||||

| Surface Treatment | Coated,Polished,Embossed, etc | ||||||

| Packing Detail | Wooden pallet either eye to wall or eye to sky | ||||||

| Application | 1)Building material such as metal ceiling, roofing, wall cladding panel, ACP; 2) Packaging such as Beverage Cans, Food Cans and Closures; 3) Road Commercial Vehicles and Trains; 4) Roller Shutters | ||||||

| Payment terms | TT, LC, Payment on Credit | ||||||

| MOQ | 5 metric tons | ||||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Aluminum foil surface, SBS roll multilayer superposition, waterproof effect is good?

- Generally speaking, SBS waterproofing membrane superimposed use, will certainly be better than the use of single layer. But the first time with the construction of aluminum thread with a little waste. Because aluminum Bu in coil plays only a reflective insulation function, so if the two house the first time it is not necessary to use the superposition with aluminum Bu, PE film can be second times, and then the aluminum coil Bu

- Q: Battery why aluminum foil as anode, copper foil as negative electrode?

- In addition to stability, it is necessary to consider the conductivity of the material, whether it can be machined thin, as well as mechanical strength, cost and other factors. Finally chose Cu and Al.

- Q: How many degrees of aluminum foil can burn?

- Just look at the thickness of your foil. If it's 0.0065 thick, the foil will burn at 200-300 degrees

- Q: What are the characteristics of aluminium foil waterproof coiled material?

- Most of the foil is shiny on one side and the other dull. Aluminum foil for food can be wrapped on both sides, and it is generally recommended to enhance the heat transfer effect with bright bread wrap

- Q: Outdoor camping in East China, with only one foil damp barrier in the tent, plus sleeping bags? Do you need inflatable mats?

- On this basis, if you can add a piece of cotton canvas to do moistureproof matBecause this is absorbent in itself

- Q: I heard that using aluminum foil and salt to add water can make the silver ring bright. Who told me what aluminum foil is and where can I buy it?

- Aluminum foil in the construction of the application is quite obvious, paste on the surface of thermal insulation material, make it more convenient and clean construction, especially the aesthetic degree to a new height. But the effect of different kinds of foil is very different, for example, fire and ordinary are not a grade.

- Q: Aluminum foil bag, VCI plastic bag, PE plastic bag, which package has good anti rust effect? It is used for the packing of iron and steel parts

- The advantage of aluminum foil is that the barrier is very good, the moisture permeability and oxygen permeability are very low, but the disadvantages are also obvious, the cost is high, opaque, not suitable for use in high humidity areas, or outer packing.

- Q: Can the potatoes be heated by foil?

- Of course, things wrapped in aluminum foil can not be heated in microwave ovens

- Q: Which bags are better, such as shield bag, aluminium bag and aluminum foil bag?

- Moisture resistant, but because it is not pure aluminum, non puncture; aluminum foil bags the best performance, anti-static, moisture-proof, puncture resistance. If you can help, but also hope to adopt

- Q: What are the materials for aluminum foil films? What are the characteristics?

- After hot rolling and cold rolling, the aluminum sheet is more than 0.3 mm in thickness. It is called aluminium plate or aluminium strip (roll shape); the thickness is less than 0.3 mm, it is called aluminium foil or aluminium foil belt (coil shape).

Send your message to us

Coated Aluminium Coil for Roofing Sheet/PE/PVDF Color Coated Aluminum Coil with God Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 1 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords