Roofing Aluminum Sheets Manufacturer Hot Sales 3003 3004 3005 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.2~320mm |

Width | <2800mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Payment | L/C ,T/T |

Brief Introduction for Cold Rolled Steel Coil

Cold Rolled Steel Coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold Rolled Steel Coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The Cold Rolled Steel Coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the Cold Rolled Steel Coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final Cold Rolled Steel Coil may be manufactured in the form of sheets, strips, bars, or other forms.

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

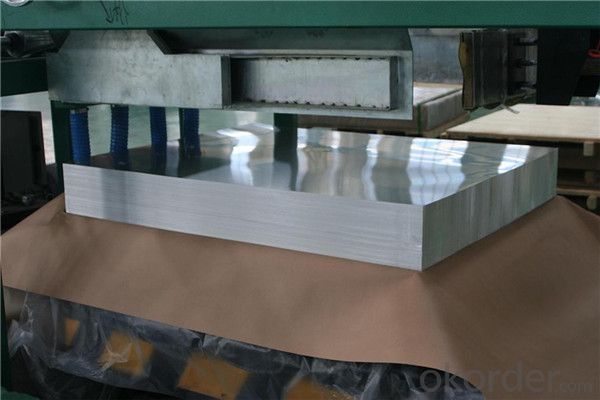

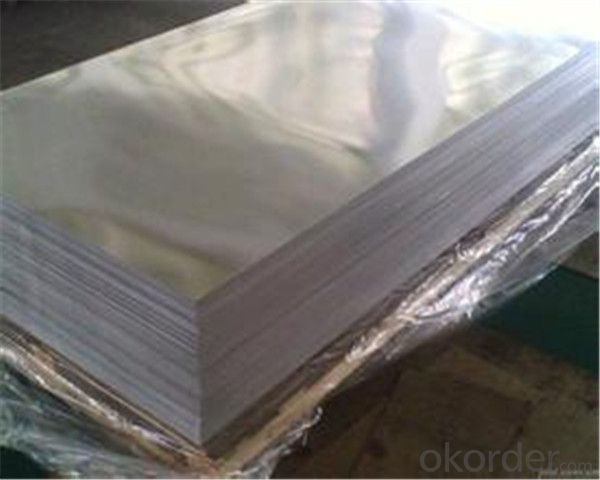

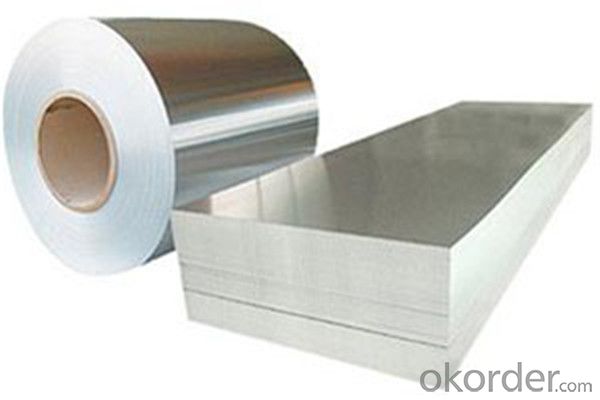

Photos of products

- Q: What are the maximum dimensions available for aluminum sheets?

- The maximum dimensions available for aluminum sheets depend on various factors such as the manufacturing process, supplier capabilities, and customer requirements. However, standard aluminum sheet sizes typically range from 0.02 inches (0.5 mm) to 0.25 inches (6.35 mm) in thickness, and widths can vary from 24 inches (609.6 mm) to 72 inches (1828.8 mm). The length of aluminum sheets can generally reach up to 144 inches (3657.6 mm). It is important to note that these dimensions may vary depending on the specific supplier or manufacturer, and custom sizes can be produced based on individual needs.

- Q: How do you ensure the surface quality of aluminum sheets?

- To ensure the surface quality of aluminum sheets, several steps can be taken. Firstly, proper handling and storage practices should be implemented to prevent any physical damage or scratches to the sheets. Secondly, thorough cleaning and surface preparation techniques should be employed to remove any contaminants or oxidation from the surface. This can include processes like degreasing, etching, or mechanical finishes. Finally, quality control measures such as visual inspections, surface roughness testing, or even automated systems can be utilized to ensure that the aluminum sheets meet the desired surface quality standards.

- Q: Is it possible to use aluminum sheets in the manufacturing process of solar panels?

- <p>While aluminum sheets can be used in the construction of solar panels, they are not the primary material for making the solar cells themselves. Aluminum is typically used for the frame or backsheet to provide structural support and protection. The actual solar cells are made from materials like silicon, which is capable of converting sunlight into electricity. So, while aluminum plays a role in the assembly of solar panels, it is not used to create the photovoltaic cells that generate power.</p>

- Q: I got nauseous the other day and that day one thing I ate was hamburger baked for 1 hour on aluminum foil with tomatoes mixed in. Is it possible the upset stomach was caused by the tomatoes reacting with the foil?

- Pie:- Shepherd’s 500g (1lb) Minced Lamb.(purple meat will do) a million great onion. 2 purple meat cubes. a million ? C Water. ? C Frozen peas. ? C Diced carrot. 2T Cornflour. 4C Potato. (mashed) ? C Grated cheese. Season to flavor. Chop onion and brown gently, upload mince and brown. disintegrate in the inventory cubes, upload 1C of water, carrots and peas. Simmer for 10 minutes Thicken with cornflour mixed with ? cup water and prepare dinner for a jiffy. opened up in a pie or baking dish and canopy with mashed potatoes. Sprinkle with cheese and bake at 190C (375F) for 20 minutes till the potato has browned and the cheese has melted. If made with purple meat it would be referred to as Cottage Pie.

- Q: How much is a square inch of a millimeter aluminum plate?

- Weight 2.68 kg / square meterThis explanation is not difficult to explain the same square metre. Why is the weight different?

- Q: I would like to make a boat, Songhua River used to know, tell the answer, good + points!

- Marine yacht with 5083, with 5456 of inland water on it, domestic Park boat 5052 will be used

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that offers several advantages for industrial shelving applications. It is resistant to corrosion, which makes it suitable for environments that are exposed to moisture or harsh chemicals. Aluminum's strength-to-weight ratio is also advantageous, as it allows for the construction of sturdy shelves that can hold heavy loads while remaining relatively lightweight. Additionally, aluminum is easy to maintain, as it does not require painting or sealing like other metals. Overall, aluminum sheets are a practical choice for industrial shelving due to their durability, corrosion resistance, and lightweight properties.

- Q: How does the thickness of aluminum sheet affect its strength?

- The strength of an aluminum sheet is directly influenced by its thickness. Generally, a thicker aluminum sheet will possess greater strength compared to a thinner one. This correlation arises from the fact that the thickness of the sheet determines the quantity of material present, ultimately impacting its ability to endure external forces or loads. Typically, the strength of a material is measured based on its capacity to withstand stress without deforming or failing. Thicker aluminum sheets have a larger volume of material, resulting in an increased number of atoms and bonds to counteract forces. Consequently, these sheets exhibit a heightened resistance to deformation or failure, thus rendering them stronger. Furthermore, thicker aluminum sheets boast a higher load-bearing capacity. Consequently, they can endure heavier loads or higher pressures without distorting or failing. The augmented thickness allows for a greater distribution of the load, thereby reducing the stress placed on individual atoms and bonds within the sheet. Nevertheless, it is crucial to acknowledge that there exists a limit to the thickness at which the strength of an aluminum sheet reaches a plateau. Once this threshold is surpassed, further increasing the thickness may not yield significant improvements in strength. This limitation arises from the influence of other material properties of aluminum, such as its crystal structure and grain boundaries, which also contribute to determining its strength. To conclude, the strength of an aluminum sheet is directly linked to its thickness. Thicker sheets possess more material, enabling them to effectively resist deformation or failure under stress. Furthermore, their increased thickness allows them to support heavier loads or endure higher pressures. However, it is important to recognize that there is a limit to the thickness at which the strength plateaus, as other material properties also come into play.

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring materials. They are known for their durability, resistance to corrosion, and ease of maintenance. Aluminum floors are often used in commercial and industrial settings due to their strength and ability to withstand heavy loads. They are also favored for their slip resistance and non-flammable properties, making them a safe choice for various applications. However, they may not be as common in residential settings due to cost and the鍐板喎 feel underfoot compared to traditional flooring materials like wood or carpet.</p>

- Q: Are aluminum sheets suitable for boat building?

- Boat building can definitely benefit from the use of aluminum sheets. This material is widely favored for its many advantageous properties. To begin with, aluminum's lightweight quality makes it a breeze to handle and transport during the boat construction process. Not only does this make things easier, but it also contributes to better fuel efficiency and overall boat performance. Moreover, aluminum boasts excellent resistance to corrosion, particularly in saltwater environments. This makes it an ideal choice for boat building, as it ensures the boat remains durable and maintains its structural integrity even when faced with harsh weather conditions. In addition, aluminum sheets offer a remarkable strength-to-weight ratio, providing a solid and dependable structure for the boat. This strength allows the vessel to withstand the various forces it encounters while sailing, guaranteeing a safe and enjoyable experience for all aboard. Furthermore, aluminum is a versatile material that can be easily molded and shaped into a multitude of boat designs. This flexibility allows for customization and the creation of unique boat structures that can meet specific requirements and preferences. Lastly, it's worth noting that aluminum is an environmentally friendly option. It is fully recyclable, which helps reduce the environmental impact of boat building and promotes a more sustainable approach to marine construction. To sum it up, aluminum sheets are unquestionably suitable for boat building due to their lightweight nature, corrosion resistance, strength, versatility, and eco-friendliness.

Send your message to us

Roofing Aluminum Sheets Manufacturer Hot Sales 3003 3004 3005 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords