Aluminum Sheets Products Manufacturers 3XXXX

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

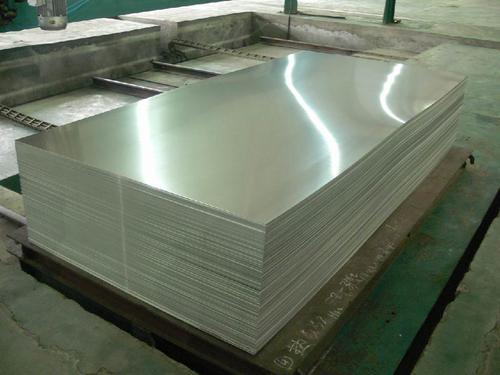

1.Structure ofAluminum Sheets D.C 3XXX Description

Aluminum Sheets D.C 3XXX is cut from aluminum coils 3xxx. Aluminum Sheets D.C 3XXX has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets D.C 3XXX is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of the Aluminum Sheets D.C 3XXX

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

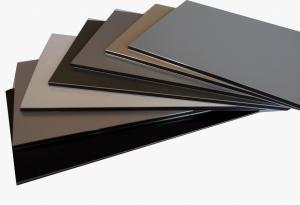

3.Aluminum Sheets D.C 3XXX Images

4.Aluminum Sheets D.C 3XXX Specification

| Alloy | AA3xxx (AA3003,AA3004,AA3005,AA3105 etc) |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thickness | 0.2mm-100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of Aluminum Sheets D.C 3XXX

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the Aluminum Sheets D.C 3XXX products.

B.When will you deliver the products?

The Aluminum Sheets D.C 3XXXwill be delivered within 35 days after receiving advanced payment or original L/C.

Many do not understand the building renovation layman should rarely come into contact with "perforated aluminum", and did not know what this aluminum is used for. We will see this application of aluminum is relatively broad, decorative effect is very good. Then, why "perforated aluminum" perforated? This is an issue that many people will answer that in times of stress can be more uniform, to a certain extent, is to strengthen the aluminum load-bearing capacity, the use of aluminum structure more solid, so this kinds of perforated aluminum range of applications is very broad, and the prospects are very bright.

The so-called "perforated aluminum" is the uniform distribution of the same size, the same thickness of the aluminum plate hole, usually made of aluminum or aluminum alloy, the thickness of the aluminum plate is a certain customary provisions, such as the thickness of the aluminum foil, internationally widely recognized that the thickness of 0.2 mm, width of 200 mm or more and a length of 16 meters below called aluminum foil. For many routine perforated aluminum expertise, we need to continue to deepen the understanding of the application of perforated aluminum, so that we can handier in architectural decoration.

For perforated aluminum mounting, we need to consider many factors, such as environmental requirements for aluminum sheet; this requirement is not only reflected in the size requirements, but also in the stability of the aluminum requirements. Therefore, the choice of a suitable size perforated aluminum sheet; we need to note is that the aluminum plate is installed. Do not underestimate the aluminum plate is installed, because the installation method, once is not correct, it will lead to very serious consequences, such as aluminum Wall fell. When installing perforated aluminum, not only in the degree of vertical aluminum very strict requirements on the aluminum plate connection requirements also must not be lost.

So, how can we effectively grasp the perforated aluminum mounting? We have to make the necessary preparations before construction before installing aluminum, such as installation materials, installation tools, and for a certain environment, we must seriously implement good perforated aluminum mounting method, under what circumstances should use what method of installation, which is the focus that we should grasp. Construction process, we must also pay attention to a lot of problems. In perforated aluminum ceiling installation, for example, we should always ensure camber ceiling keel, it is necessary to have a solid formation, which requires the full use of the boom.

Perforated aluminum sheet in our daily lives is not uncommon, but very few people would know that is perforated aluminum. Today many public places to use perforated aluminum curtain wall it will not only beautiful, but also in the firm are also very good.

- Q: Can aluminum sheets be used in aerospace applications?

- Indeed, aluminum sheets find utility in aerospace applications. The aerospace industry extensively relies on aluminum owing to its remarkable amalgamation of strength, lightweight characteristics, and corrosion resistance. It finds application in diverse aircraft components including the fuselage, wings, and structural panels, wherein reducing weight is paramount for enhancing fuel efficiency and performance. Moreover, aluminum sheets can be conveniently fabricated and molded into intricate forms, rendering them apt for a multitude of manufacturing procedures in the aerospace sector.

- Q: How much is the price of the 6061 aluminum plate?

- You ask the question is not detailed enough, because 6061 aluminum thick and thin prices are different, domestic and imported prices are different, domestic quality of different prices are also different.

- Q: Can aluminum sheets be used for air ducts?

- Yes, aluminum sheets can be used for air ducts. Aluminum is a commonly used material for air ducts due to its lightweight, durable, and corrosion-resistant properties. It is also easy to work with and can be easily shaped and formed to fit various duct designs.

- Q: Can aluminum sheets be embossed or textured?

- Yes, aluminum sheets can be embossed or textured using various methods such as roll embossing or mechanical texturing.

- Q: What are the specific rules or benchmarks that must be followed when utilizing aluminum sheets for construction purposes?

- <p>Yes, there are special regulations and standards for using aluminum sheets in construction projects. These include material specifications, thickness, and strength requirements as per the American Society for Testing and Materials (ASTM) standards, such as ASTM B209 for aluminum sheet and plate. Additionally, the International Building Code (IBC) and local building codes provide guidelines for the use of aluminum in construction. These standards cover aspects like fire resistance, structural integrity, and weather resistance. Compliance with these regulations ensures safety, durability, and compliance with construction laws.</p>

- Q: How do aluminum sheets perform in terms of weldability?

- The weldability of aluminum sheets is generally good because of their low melting point and excellent thermal conductivity. Various techniques, such as TIG welding, MIG welding, or spot welding, can be used to weld aluminum sheets. However, there are a few factors that can affect the weldability of aluminum sheets. First, it is necessary to ensure that the surface of the aluminum sheet is clean and free from contaminants like oil, grease, or oxide layers. These contaminants can have a negative impact on the weld quality. Therefore, it is crucial to clean and prepare the surfaces to be welded properly. Second, aluminum sheets have a high thermal conductivity, which means that heat dissipates quickly. This can make it difficult to control the temperature during the welding process. To ensure a successful weld, it is important to have a skilled and experienced welder who can adjust the welding parameters accordingly. Lastly, aluminum sheets have a high coefficient of thermal expansion, which can result in distortion or warping during welding. To minimize these issues, techniques such as tack welding or clamping may be used to hold the sheets in position. In conclusion, aluminum sheets generally have good weldability due to their low melting point and excellent thermal conductivity. However, achieving high-quality welds and avoiding potential issues like contamination, distortion, or warping requires proper surface preparation, skilled welding techniques, and careful temperature control.

- Q: Are the aluminum sheets corrosion-resistant?

- Indeed, aluminum sheets exhibit resistance to corrosion. When aluminum is exposed to oxygen, a protective oxide layer naturally develops, effectively inhibiting corrosion. This oxide layer acts as a shield, separating the aluminum from its surroundings and granting the sheets exceptional resistance against corrosion. Moreover, aluminum sheets can undergo additional treatments such as coatings or anodizing processes, further amplifying their resistance to corrosion. Consequently, aluminum sheets are widely favored for applications where the necessity for corrosion resistance is paramount.

- Q: Are aluminum sheets suitable for solar reflectors?

- Yes, aluminum sheets are suitable for solar reflectors as they have excellent reflective properties, high thermal conductivity, and are lightweight, making them an ideal material for maximizing solar reflectance and minimizing heat absorption.

- Q: Can aluminum sheets be bent?

- Yes, aluminum sheets can be bent as they have malleable properties that allow them to be easily shaped or formed into desired angles or curves.

- Q: What are the different types of alloys used in aluminum sheet?

- Aluminum sheet incorporates a variety of alloys with distinct characteristics. Some of the most frequently employed alloys include: 1. The 3003 alloy is renowned for its exceptional corrosion resistance and finds utility in situations where moisture exposure is a concern. It is also highly malleable and can be easily welded, making it a popular choice for various structural components. 2. The 5052 alloy boasts remarkable corrosion resistance and excellent formability. It is commonly used in marine and automotive applications, as well as architectural elements. 3. The 6061 alloy provides unparalleled strength and is widely utilized in applications demanding high structural integrity. It is commonly found in the aerospace and marine industries, as well as in the construction of heavy-duty machinery. 4. The 7075 alloy is celebrated for its exceptional strength-to-weight ratio and is extensively employed in aerospace and defense applications. Furthermore, it is utilized in the manufacture of bicycle frames, rock climbing equipment, and other high-performance applications. 5. The 2024 alloy is renowned for its strength and outstanding fatigue resistance. It is frequently utilized in aerospace applications, as well as in the production of structural components and fasteners. These aforementioned examples merely scratch the surface of the multitude of alloys used in aluminum sheet. Each alloy possesses its own unique properties and advantages, rendering it suitable for specific industries and applications.

Send your message to us

Aluminum Sheets Products Manufacturers 3XXXX

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords