4W S Grade 156.75*156.75mm Polycrystalline Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

4W A Grade 156.75*156.75mm Polycrystalline Solar Cell

Solar Module Summarize

Solar Module is the core part of solar PV power systems,also is the highest value part of it. The function of Solor Module is to convert the sun's radiation to electrical energy, or transfer it to battery and store in it, or to drive the load running.

The Product has been widely used in space and ground, it mainly used for power generation systems, charging systems, road lighting and traffic signs areas. It could offer a wide range of power and voltage, and with high conversion efficiency, and long service life.

Main Characteristic

Long Service Life

High Efficiency Solar Cells

Special Aluminum Frame Design

High Transmission, Low Iron Tempered Glass

Advanced Cell Encapsulation

APPLICATIONS

Solar power stations

Rural electrification, Small home power systems

Power supply for traffic, security, gas industry

12V and 24V battery charging system

Other industrial and commercial application

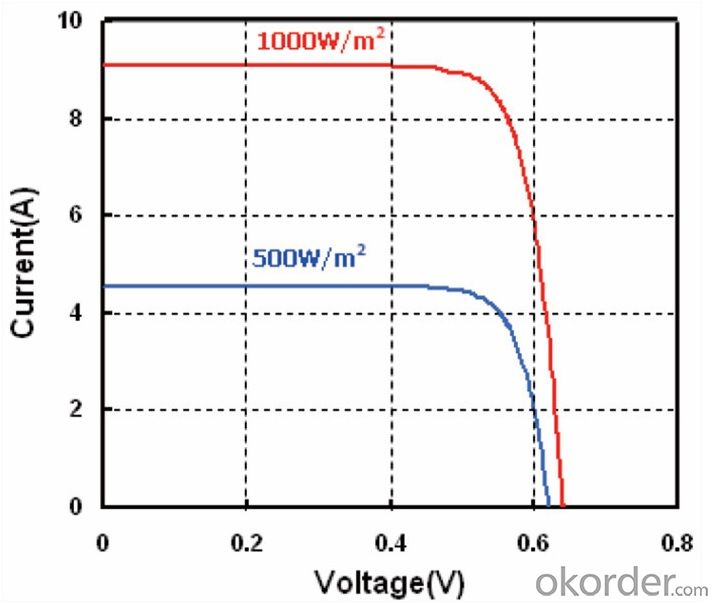

Typical I-V curve

Product Show

Warranties

6Inch 2BB Polycrystalline Multi Solar Cells Mono Solar Cell

For c-Si panel: 25years output warranty for no less than 80% of performance, 10 years output warranty for no less than 90% of performance. Free from material and workmanship defects within 5 years.

For a-Si panel: 20 years output warranty for no less than 80% of performance, 10 years output warranty for no less than 90% of performance. Free from material and workmanship defects within 2 years.

- Q:What is the average lifespan of a solar silicon wafer?

- The average lifespan of a solar silicon wafer can vary depending on various factors such as the quality of the wafer, the manufacturing process, and the conditions in which it is used. However, on average, a solar silicon wafer can last anywhere from 25 to 30 years.

- Q:What is the purity level of the silicon used in solar silicon wafers?

- The purity level of the silicon used in solar silicon wafers is usually around 99.9999% or higher.

- Q:How does the efficiency of a solar silicon wafer change with humidity?

- The efficiency of a solar silicon wafer generally decreases with increasing humidity. High humidity levels can cause moisture to accumulate on the surface of the wafer, leading to a decrease in the wafer's ability to convert sunlight into electricity. This moisture can create a barrier that reduces the amount of light reaching the semiconductor material, thereby reducing the overall efficiency of the solar cell. Furthermore, humidity can also affect the electrical properties of the silicon material, leading to increased resistance and decreased performance. Therefore, it is important to consider humidity levels when evaluating the efficiency of a solar silicon wafer.

- Q:Can solar silicon wafers be used in solar-powered waste management systems?

- Yes, solar silicon wafers can be used in solar-powered waste management systems. The wafers can be used to generate solar energy, which can then be utilized to power various components of waste management systems such as sensors, sorting machines, and waste compactors. This helps in creating an eco-friendly and sustainable waste management process.

- Q:What is the role of solar silicon wafers in rural electrification?

- Solar silicon wafers play a crucial role in rural electrification by being the key component in solar panels. These wafers are responsible for converting sunlight into electricity through the photovoltaic effect, providing clean and sustainable energy to rural communities. By harnessing solar power, these wafers enable the generation of electricity in remote areas without access to traditional power grids, improving the quality of life, promoting economic development, and reducing reliance on fossil fuels.

- Q:What are the main challenges in producing solar silicon wafers?

- The main challenges in producing solar silicon wafers include the high energy consumption during the production process, the high cost of raw materials and equipment, the need for high purity silicon, the complexity of the manufacturing process, and the environmental impact of the various chemical processes involved. Additionally, ensuring consistent quality control and minimizing defects in the wafers pose significant challenges to manufacturers.

- Q:Do solar silicon wafers emit any pollutants or greenhouse gases during operation?

- No, solar silicon wafers do not emit any pollutants or greenhouse gases during operation. They are a clean and environmentally friendly source of energy.

- Q:How is the surface roughness of a solar silicon wafer measured?

- The surface roughness of a solar silicon wafer is typically measured using a technique called atomic force microscopy (AFM). AFM involves scanning a tiny probe over the surface of the wafer and measuring the forces between the probe and the surface. The data obtained from AFM can provide precise information about the surface roughness, including the average roughness value and the height distribution of surface features.

- Q:What's the difference between a silicon wafer and a battery?

- Silicon chip, is a large piece of silicon, cut into a filmSolar cell, the mainstream is the silicon wafer made of crystalline silicon solar cells, or other solar cells: thin film solar cells, amorphous silicon solar energy, solar cells and so on

- Q:How is a temperature coefficient measured in a solar silicon wafer?

- A temperature coefficient in a solar silicon wafer is measured by subjecting the wafer to different temperature conditions and observing how the electrical output or efficiency of the solar cell changes with temperature. This allows researchers to determine the rate at which the performance of the solar cell is affected by temperature variations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

4W S Grade 156.75*156.75mm Polycrystalline Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products