3000Ton-6000Ton Soya Bean Storage Steel Silo

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 50000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

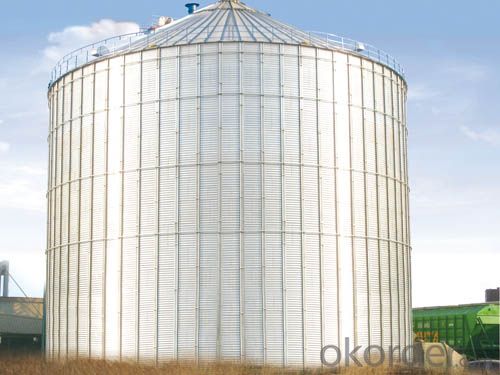

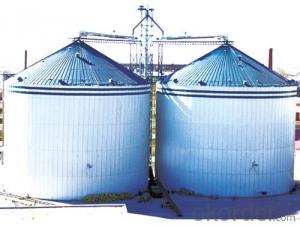

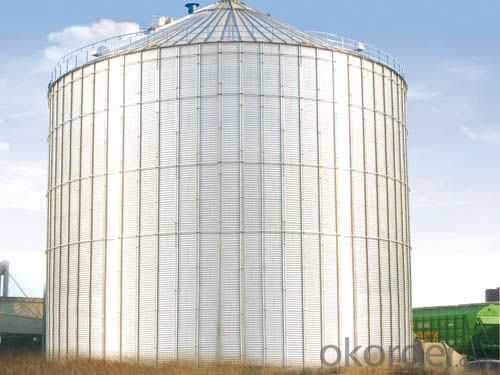

3000Ton-6000Ton Soya Bean Storage Steel Silo

Main Structure

1.Soya bean storage steel silo

2.Galvanized grain silo

3.Assembly bolted silo

4.Easy to install and maintain

3000Ton Soya Bean Storage Steel Silo :

Silo Specification:

Model : TCK17414

Diameter : 17.426m

Layer : 14

Volume : 4074m3

Capacity : 3136t

Eave height : 15.735m

Total height : 19.780m

Brief introduction :

We could design, calculate, install and maintain grain steel silos according to your different needs.

We could manufacture various kinds of silos, such as flat bottom steel silo and hopper bottom steel silo, the diameter ranging from 1.8 to 30m, capacities from 5 to 12000 tons per storage bin.

In addition, we could offer our clients material handling system, such as, drying system, cleaning system, bucket elevators, drag conveyors and belt conveyors. One source for all your grain storage, drying, packing, and material handling needs.

Life circle of products can come up to 20-50 years. Our products are completely comply with the national standards "The Grain Codes of Silo Design" and have reached the advanced national levels in performance.

Our products have been exported to Argentina, Australia, America, China, Ethiopia, Honduras, Iran, India, Korea, Malaysia, Myanmar, Poland, Pakistan, South Africa, Sudan, Serbia, Thailand, Ukraine, Vietnam, etc.

3000Ton Soya Bean Storage Steel Silo Features :

•A world leader in steel corrugated storage bin supplying, TSE offers the strongest and heaviest storage silos in the industry with capacities exceeding 15,000 MT. Our silo sidewall is roll-formed using high quality galvanized steel sheets; Prime high tensile steel up to 450 MPa. Thicker sidewall steel sheet allows us to provide larger silos with our designs.

•Grain silo includes ROOF,BODY,ROOF HANDRAIL,VENTS,MANHOLE,DOOR;

•The silo roof and body is made of corrugated galvanizing steel sheets,the galvanizing mass is 275g/m2 as standard design, according to some customers special request, 350g/m2 and 400g/m2 are options for their needs;

•Silo is anti-seismic.

Advantages Of Steel Silo :

1. Lower basic cost with lightweight, low request for foundation, low consumption of steel.

2. High degree of standardization. We can produce the standard components which can be installed on-the-spot.

3. Simple, easy and efficient to install within a short amount of time due to superior component design which are connected by standard bolts.

4. Easy to understand . The bolted silo is equipped with relevant accessories, such as: conveyor, ventilation, drying and monitoring devices, etc. to ensure the quality and safety of the material stored in the silo.

5. Easy to maintain. As the parts of the silo are connected by standard bolts, so it is easy to remove or repair it.

6. Low cost and long tenure of use. The cost of bolted silo is just 35%-50% of the cement silo with the same specification; and its life span can reach 30 years.

Pictures

- Q: takes over a nuclear silo in kansas and points at downtown moscow for the russians have planted a bomb in the saudi arabian oil fields to devastate america

- That might be Seven Days In May with Burt Lancaster and Kirk Douglas.

- Q: All I can remember is thinking that all of that grain would now be ruined.

- In Witness a guy gets buried in it.

- Q: What is organisation Silos? How the silos endanger the company? How can we stop working in silos?

- Organization Silos are when individual people, departments, or companies, conduct business in a vacuum without taking into consideration the impact their actions have on the entire organization. For instance an accounts payable department always pay on time within the conditions of the purchase order but accounts receivable don't collect cash to support the amount of money going out. Both departments work along merrily without any communication and both feel they are meeting their responsibilities however cash is drained and the corporation continues to borrow money at a high interest rate to support paying vendors and general expenses. There is always an opportunity to share information and look at the corporate wide impact and ask if it makes sense to do business in the way we always have. A process flow of all activities should show you the interdependency of one department or function to another. Sharing of information problems and actions implemented to correct these issue are vital to the ongoing efficient operations. Silos are basically large vertical buildings that separate and store material on a farm. When organizations run in silos they are not looking at other aspects and the cause and effect of various activities, so it is referred to as working in a silo.

- Q: A silo is to be constructed in the form of a cylinder (only 1 of 2 bases included) topped by a hemisphere. The construction cost per square unit of surface area for the hemisphere is 2.0 times as much as for the cylinder and the volume must be 840000 cubic feet. If construction costs are to be minimized, what should the radius be?

- I was given this problem on a final exam as a freshman. You need to minimize the surface ares. You know that the area of the top is (Pi)*r^2 and the area of the cylinder portion is 2*(Pi)*r*h where r is the radius and h is the height. At this point, it looks like there are two unknowns. This is where you bring in the volume. You vet: V = (Pi)*r^2 * h So: 840,000 = Pi)*r^2 * h You can use algebra to get 'h' in terms of r and go back to the first equation. This puts surface area as a function of r. Take the first derivative and solve for r

- Q: ....and the thermonuclear bombs glare gave proof through the night that Los Angeles was not there....

- Something is going to happen, and I believe sooner, rather than later, unfortunately..... I doubt it'll be a thermo nuke, but your guess is as good as anyone's........

- Q: A grain silo has a cylindrical shape. Its diameter is 18ft, and its height is 46ft. What is the volume of grain that can be stored in the silo?Round the answer to the nearest cubic foot

- The volume of the cylinder is pi*r^2*h where h is the height and r is the radius. So r=9, h=46. Then 81*46*pi is the volume of the cylinder. Or 3726pi = 11706ft^3

- Q: A silo is to be constructed in a form of a cylinder (only 1 of 2 bases included) topped by a hemisphere. The construction cost per square unit of surface area for the hemisphere is 2.8 times as much as for the cylinder and the volume must be 730000 ft^3. if construction costs are to be minimized, whats should the radius be?

- OK. Here is what I get. Not sure if it is correct but it looks like it might be. Say 'x' is cost per unit area for the cyclinder (Ac) then the cost per unit area for the half sphere (As) is 2.8x. You can then create an equation for cost (C) using this: C = 2.8*x*As + x*Ac Using equations for area and knowing that you only have half a sphere you expand this to. . . C = 2.8*x*(2*pi*r^2) + x*(pi*r^2 + 2*pi*r*h) You can find h with respect to r using the volume equations. 2/3*pi*r^3+pi*r^2*h = 730000 so h = (730000-2/3*pi*r^3)/(pi*r^2) The cost equation then becomes. . . C = 2.8*x*2*pi*r^2 + x*pi*r^2 + x*2*pi*r*(730000-2/3*pi*r^3)/(pi*r^2) Simplify and you should get. . . C = 16.547*x*r^2 + x*1460000/r Then find the derivative. . . dC/dr = 33.09*x*r - x*1460000/r^2 Find the min by setting the derivative to zero. . . dC/dr = 0 = 33.09*r - 1460000/r^2 1460000/r^2 = 33.09*r r^3 = 44122 r = 35.34 Hope you could follow that.

- Q: a silo is to hold 1000 m^3 of corn.what dimensions will minimize surface area? plzz show the full steps

- I'm not sure what you mean by silo but create to equations one for Volume and one for surface area in two variables (x and y). But you know what the volume equation equals then you can solve for either of the two variables in the volume equation and the substitute that into the surface ares equation. Then take derivate, equate it to zero and solve for the variable. Then you solve for the other variable. Hope this helps!

- Q: i always see farm trucks filling up water and bringing it to their farms. do all farms have to do this? also how is this done? is there a large water silo or some kind of reserve that is filled up once a week or what? Can you drink the water from those water stations you often find near towns for farm trucks?

- our farm doesn't what i think your seeing is a spray truck - spraying the fields with chemicals - the concentrated liquid is put into the tanker first and then bulked with water to disperse onto the fields some of the very large farms do this in my area - its faster and cheaper to have the city fill that tanker then to wait for a couple hours on the farm well head silo's are for animal fodder or bulk feed sometime silage for cows no that water that is at the stations is not safe to drink

- Q: How do i get the lauch codes and missile key in the multiplayer level, The Missile Silo. where can i find these two things?

- go okorder

Send your message to us

3000Ton-6000Ton Soya Bean Storage Steel Silo

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 50000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords