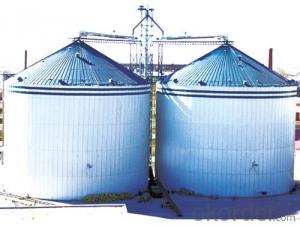

1000Ton-6000Ton Walnut Grain Storage Steel Silo

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 50000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1, Galvanized steel silo wall

2, Storing grain for long time

3, Long time life span

4, Easy to install and maintain

Walnut Grain Storage Steel Silo

Product Description

Application

Hopper bottom steel silos are widely used in storing grain, seeds, flour, feed, cement and chemistry, which need to be cleaned continually.

Features

Hopper bottom steel silo are famous for its automatic discharging process.

The grain inside silos could unload automatically due to gravity, and very efficient;

The steel legs are made of H beam which have good quality and bearing.

2 kinds of angle-45 degree and 60 degree, among which the 60 degree conical-bottom is usually used to store larger pellet and powdered materials of high viscosity.

Hot dip galvanized steel sheets, 275g/m2 coating galvanizing.

Bolt and screw connected, assembly and easy maintenance.

A Completed Grain Storage System

General Flow path: Truck loaded with grain coming--dumping pit --conveyor--pre-cleaning--elevator--hopper silo--conveyor--truck or workshop or packing machine

*We will design for you as per your requirements.

Our Services

Accessory equipments of the hopper steel silo:

Handling equipment

Pre-cleaning

Ventilation system

Installation:

The installation of silos can be carried out by different ways.

*If the client wants to install silos by themselves, we could offer detailed instruction, and we'll give our quickest response to deal with any question in the process.

*We could also send our engineer to supervise the installation process. The client could find local workers for the installation work and our engineer will help them during the process.

*If the client needs, we could send our installation team for the whole installation issue.

- Q: how do you exit the first mission in the missle silo? go to the roof or what?

- actually pretty easy. immedately turn right and there's a ladder.. climb it. then look around (might be right beside you) is a rope) use it. climb as fast as you can. you only have like 1 min to get to that rope and high enough on it i've beaten the game.. if you need any help you can email me

- Q: how was feed loaded into the top of wooden farm silos?

- They used steam traction engines to drive a spindle on a conveyor.There are pictures of such set ups in early agricultural books. Although the silo's weren't that high, the angle of the elevator wasn't that great. Then the blower was invented which still lifted the grain, and still driven by a steam traction engine. This is the first time Ive seen photo's of this set up. I have books on Cimbra equipment for grain and seed dressing, which all have electric motors attached. The first records for Cimbra, are about 1947. But, I have no information on how the grain was stored before hand. I suspect Jute bags were the main tool for storage, which gave all the vermon in the locality a free feed, when ever they wanted it. The place I work at have all the computerised high volume transfer units, with our average silo being 400 tonnes. A big change from the early days.

- Q: I like this But what do you think of this short video

- I'd definitely live in it; seriously, I wonder what it would be like to combine two or three to make a complete home.

- Q: They live in Virgina. Some quot;good old boysquot; changed Indiana's Constitution decades ago to accommodate Lugar being a non-resident for the State he supposed to represent. The election board ruled he could not use the bogus address any more, because it's not his house. They did rule he could use the family farm, which has NO habitable buildings. I think they need to move into the corn silo, but it needs running water and electric.This situation has never been challenged in the Courts, where US Constitution would trump State Constitution.

- Excellent comment and question. Santorum was voted out when it became known his home in Pittsburgh had not been lived in for years and his wife and children worked and attended schools in Virginia. Ted Stevens lived in D.C. area and maintained a home in Alaska, although he did make numerous trips to his home state to hunt and fish. Maybe there should be a law on the books for national representatives to actually live in the state they represent. One of the biggest issues we hear about is the guy/gal that is elected, goes to D.C. and morphs into an Inside the Beltway insider. They forget the issues back home and start to listen to other Insiders and make decisions based on beltway mentalities and lobbyist. They should all be required to go home, stay home, and reconnect for at least 4months each year, 4 continual months no foreign research trips, no campaigning for others (ie: President, or other outside the state politician). Maybe then they would still understand and know those that put them in office the first time they ran.

- Q: Google Earth says there is a missle silo somewhere below Tri-c west campus. Is that true???

- take a shovel see for you're self

- Q: I work at a grain silo and I am trying to figure out if I should tell truck drivers to turn off their engines while the vehicle is being weighed. I don't know if the loads created by the vibrations from a running engine will significantly affect the reading while weighing heavy trucks. I hope somebody can give me an answer. Thanks.

- FYI: weight is not a verb. Weigh is the verb. While there will surely will be vibrations that will yield instantaneous errors in the measurement, these errors do not amount to any AVERAGE steady state errors in the measurement. The midline of the scale reading as a function of time will measure the same value whether the engine is running or not. Many weigh stations actually tell the drivers to weigh while in motion, just to keep a good flow of traffic. In fact, it is possible to cheat these scales with clever braking and accelerating. Braking will load the front wheels more, and accelerating will load the rear wheels more. This is due to the wheel supports needing to constrain with a torque against the truck tipping forward and backward, as it accelerates. I actually know people who mastered this skill of cheating the scales. If done right, you can cheat the scales by 5%. Of course though, there are speed limits to the weigh stations. Plus it is very difficult to change the speed of such a massive truck.

- Q: A silo is to be constructed in the form of a cylinder surmounted by a hemisphere. The cost of construction per square foot surface area is twice as much for the hemisphere as for the cylinder. Determine the dimensions to be used if the volume is fixed (100m^3) and the cost is to be minimum.plz show stepsthanks in advance-lara

- Let V = volume of silo V = volume of hemisphere + volume of cylinder Volume of hemisphere = (2/3)(pi)r^3 Volume of cylinder = (pi)r^2h where r = radius of cylinder = radius of hemisphere h = height of the cylinder Since V = 100, 100 = (2/3)(pi)r^3 + pi(r^2)h and solving for h h = (100/(pi*r^2)) - (2r/3) S = Surface area of silo = surface area of hemisphere + surface area of cylinder Surface area of hemisphere = 2(pi)r^2 Surface area of cylinder = pi(r^2) + 2(pi)rh Therefore, S = 2(pi)r^2 + pi(r^2) + 2(pi)rh since h = (100/(pi*r^2)) - (2r/3) and substituting it in the above equation, S = 2(pi)r^2 + pi(r^2) + 2(pi)r[100/(pi*r^2)) - (2r/3)] Simplifying the above, S = 2(pi)r^2 + [(pi)r^2 + 200/r - 2(pi)r^2/3] S = 2(pi)r^2 + [(1/3)(pi)r^2 + 200/r] Since cost of hemisphere is twice that of the cylinder, then C = cost = 2*2(pi)r^2 + 1*[(1/3)(pi)r^2 + 200/r] C = 4(pi)r^2 + (1/3(pi)r^2 + 200/r C = (13/3)(pi)r^2 + 200/r Differentiating C with respec to r, (dC/dr) = (26/3)(pi)r - 200/r^2 and setting (dC/dr) = 0 and solving for r, (26/3)(pi)r - 200/r^2 = 0 Simplifying the above, 26(pi)r^3 = 600 Solving for r, r = 1.94 meters Now, that r is known, h can be determined by using the above derived formula of h = (100/(pi*r^2)) - (2r/3) Substituting r = 1.94. h = 7.16 meters Dimensions of the silo are: r = 1.94 m h = 7.16 m CHECK: First check: V = (2/3)(pi)(1.94)^3 + pi(1.94)^2(7.16) V = 15.3 + 84.7 = 100 m (this checks with the original condition of the problem that the volume of the silo is fixed at 100 m^3). Second check: Take the second derivative of the original function, i.e., (d^2C/d^2r) = 400/r^3 and since the second derivative is positive (greater than zero), then it confirms that the calculated dimensions for r and h will indeed yield the minimum cost.

- Q: Joey has 3 silos. The large silo has a diameter of 24. The smallest silo has a diameter 1/3 of the largest sil?

- 3 silos. We are told that there are: Large, Smallest and Largest. We are also told how big the Large one is (d = 24) but only that the diameter of the Largest is 3 times the Smallest. Clearly, the Large one is actually the middle sized silo.

- Q: Nothing too fancy, something we could do at home. For a science project so keep it simple. :)

- When a corn silo blows up, it's because of a dust explosion. In a dust explosion, there is a very large volume of air surrounding a small volume of fine particles and an ignition source. Take a coffee can with a plastic lid. Cut a small hole in one side near the bottom. Attach a piece of rubber hose so that it sticks into the can a small amount aimed down to the centre of the can. Put a 1/4 cup of talcum powder in the can. Put a small candle in there too. Light the candle. Snap the plastic lid in place. Blow hard into the rubber hose and watch the results. CAUTION: Don't get too close to the can until you have tried it a couple of times to see how it works and do all your experimenting outside. When you see the lid go flying off for the first time, try to imagine what kind of force is released in a silo explosion.

- Q: I've played this game on Visual Boy Advance. So i'm not really sure the real name but it written there ' Harvest Moon' only.I just want to know how to make fodder to feed chicken and cow. The tutorial just says to take the fodder from the silo but HOW TO MAKE ONE!!!???Please anyone......

- if its friends of mineral town: for cow fodder: grow grass (which can be bought at the supermarket) and when it is fully grown, cut it with your sickle and it will automatically appear in the silo (where the fodder is kept). you'll be able to cut your grass from spring to fall OR you can buy it from barley in yodel farm, he'll send it to you. for chicken feed: grow corn in the summer (which can be bought at the supermarket) and when it has grown, pick it up and put it in the water mill (it's light the brown building attached to your chicken coop with the watermill in the river) 1 piece of corn will get you 30 chicken feed. you just face the light brown building and put the corn in there (facing the black slots) and the feed will automatically go into the silo (where the feed is kept) OR you can buy it from lilia in the poultry farm, she'll send it to you. for most of the other harvest moons: for cow feed: it's the same as the above only you'd buy it from someone else depending on the version. for chicken feed: you have to buy it. if you have any more information (since you don't have the game version's name), just list it. like the places, the people, etc. and it wouldn't be hard for me to figure out which version you were playing.

Send your message to us

1000Ton-6000Ton Walnut Grain Storage Steel Silo

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 50000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords