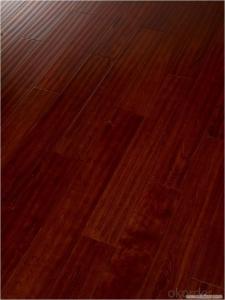

Yongsen Classic Red Oak Color Antique Ecological Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Material properties

Oak is widely used for decoration materials and furniture making, is the excellent material properties: heavy oak hard straight grain, coarse structure, elegant color texture appearance, very high mechanical strength, wear resistance, but the wood is not easy to dry sawing and cutting. Oak is widely used for decoration materials and furniture making, is the excellent material properties: heavy oak hard straight grain, coarse structure, elegant color texture appearance, very high mechanical strength, wear resistance, but the wood is not easy to dry sawing and cutting. Oak is a large number of applications in the decoration materials, furniture, sports equipment, shipbuilding, vehicles, flooring, etc.. Post surface of plywood as the ideal timber production slices of white oak, red oak is, the pattern there are straight and perpendicular to the grain of the difference, straight grain is beautiful, the price is slightly expensive.

2、Product Characteristics

1, has a more distinct mountain wood, and touch the surface with good texture;

2, toughness is excellent, can be processed into a variety of needs, a variety of bending, quite a sense of beauty.

3, solid texture, manufactured goods firm structure, long service life, used in many antique lattice windows and doors production;

4, the stability of the floor is relatively good.

5, higher grades, suitable for the production of European style furniture, Chinese classical furniture, a sense of thick, mahogany furniture is dignified and calm, but the price is lower than mahogany furniture. Cool, comfortable;

6, oak fine texture, tube inner hole more transgressive filling, is not easy to absorb water, corrosion resistance, strength, Europe and the United States used to store wine.

7, texture rich, beautiful, natural pattern;

3、Parameter

1 material: Oak

Origin: Zhejiang

Style: European classical

Standard: Class A

Applicable scope: bedroom

Pattern: Wood

Special purpose: anti-corrosion

Plate finish: 1

Surface shape: hand grasp pattern

Residual depression: no

Formaldehyde release rate: E1

Resist pressure: 1

Wear layer thickness: 3mm

Wear resistance: 1

Fading (grade): 1

Floor thickness: 18mm

Color: Red

Specifications: 910*122*18

4、Reference pictures

- Q:my flooring is hollow underneath in some areas, how can I have this taken care of?

- Call the installer back. Poor job

- Q:Wood composite floor thickness which? Which is better?

- You may also see through the above, in these two kinds of inside, it is obvious that the three layer, the apparent surface of the thickness of your tree is much higher than the multi-storey, so this kind of floor belongs to the top floor;And more than 7 layers, whether it is the 9 or the 11 layer, the relative cost is much lower, so the low-end;

- Q:Want to decorate the home, I heard that the solid wood floor care convenience, composite floor to play regular wax like. But it is said that the solid wood floor for a long time there will be a gap, and step up will quack creak. Want to know this is not the case, by the way, I recommend what to buy the floor of the brand, thank you ~ ~ ~

- So I suggest you go to the formal decoration market, get the floor, see is not the real wood. Now the level of fraud is very high, however, a simple look from the side, you can see it. Or secretly with a nail with a wood, if it is false, on the leakage level.Then, must hear a smell of the floor, is not very kind of smoked flavor, and the eyes will have a feeling of want astringent tears. If not, it proved that the floor paint is environmentally friendly.Any manufacturer of wood products, have environmental protection and ordinary type, so the same thing, expensive

- Q:Solid wood flooring is a tax within the scope of consumption

- First, the excessive consumption of human health, social order and ecological environment caused by the harm of special consumer goods, including tobacco, alcohol and wine, firecrackers and fireworks, wooden disposable chopsticks, wood flooring, etc..Solid wood flooring consumption tax rate of 5%

- Q:Model 8703, the solid wood floor of a plate

- Wood floor types are: solid wood flooring, laminate flooring, solid wood flooring, bamboo flooring, such as more than a dozen. To realize the choice of the kind of floor, and then have the goal to focus on the selection decision.

- Q:We bought a house with engineered oak hardwood floors that look to be 3mm thick. We're trying to determine if we can refinish them or if we just need to replace them, but we're not sure how to tell if they have am aluminum oxide finish. Is there a way to tell without knowing the manufacturer or any other related info?

- Not so much, no. There's no test that you can do at home that can tell you if these engineered floors have an aluminum oxide finish or another type of modern finish. But unfortunately, chances are it's AO. Most engineered floors, especially those that aren't super expensive (so floors bought through THD and etc.) are AO.

- Q:In addition to the bathroom, kitchen and balcony, I would like to decorate the whole house is covered with solid wood, because I like to sit on the floor, you have a home shop wood? The weather is relatively humid in the south, it will be difficult to take care of it? Because it is too much, so I intend to fight! Ha-ha

- (3) the laying of a good moisture-proof measures should be done, especially on the ground floor and other wet places. Moisture proof measures are coated with moisture-proof paint, moisture-proof film, the use of matting treasure, etc.. (4) keel should be flat and firm, not to use cement reinforcement, it is best to use expansion bolts, nails, etc.. (5) the keel should be used to hold a strong grip of larch, wood and other wood. The moisture content of the keel or floor should be close to the moisture content of the floor.

- Q:most durable, Engineered, hardwood, bamboo, laminate floors?

- well hard wood is better. very expensive and if damaged hard to replace, but it lasts centuries and looks elegant. bamboo is much cheaper and easier to replace. i would get one that has a high durable gloss. that is your best protection from damage. rememeber to save some of what ever you buy so if ever needed you can replace it with the same kind of wood, and it will age and color the same.

- Q:Some solid wood floor light, which is good, how to separate

- Several South American wood species, balsam, heavy wood ants and incense two wing bean three is preferred, balsam many places called red sandalwood, the price is very high (teak and better), but the density is high, the stability is also very good, and the color is red, the love is Chinese. Heavy wood ants in some places called rosewood, is actually wrong, now all the red sandalwood on the pounds, but it is indeed very good, belongs to a class of very high density, stability is also very good, but also more color, darker than the price well, not teak Liquidamberis Pigeonpea, but also high enough the. Two winged beans with a lot of weight...

- Q:Because the house is to be demolished, the new solid wood flooring is not a pity, so I would like to ask if we can get the floor to the new premises again?

- Solid wood flooring is a natural wood after drying, processing of the formation of ground decorative materials. Also known as log flooring, wood is directly processed into the floor. It is the natural growth of the wood texture, is a poor conductor of heat, can play a role, cool comfortable and safe use, is an ideal material for the bedroom, living room, room decoration

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Yongsen Classic Red Oak Color Antique Ecological Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords