ceramic wall tiles for bathroom & kitchen / 2016 new styles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

- Option:

- 300*600 mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Ceramic wall tiles for bathroom & kitchen / 2016 new styles

Advantage:

1. All ceramic wall tile are PREMIUM AAA Grade. We established an independent dept to inspect all goods before shipment.

2. OEM service: We can make your brand on the package or even on the tiles. Also, you can customize your own designs with us.

3. Special dimensions are available according to request.

4. More than ten years experience and very professional team in exporting to ensure your order more smooth.

5. On time delivery, in general 15~20 days.

6. Best service: customer can follow their order situation any time, no matter on product line, warehouse or shipment.

7. Own designer team ensure the designs are newest and adjust for pure and right color.

Package Details :

8 pcs/carton

1080 cartons/1*20 GP/with pallet

27 Ton/ 1*20 GP

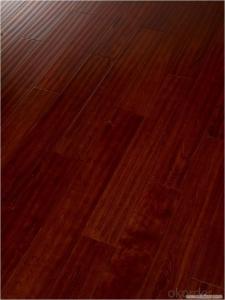

Product effect:

Company information:

Our company founded in 2004,is a professional manufacturer of all types of ceramic tiles and porcelain tiles,covering an area of 180,000 square meters.Currently we have over 1000 staff,including 72 research & development talents with years'experience in this field.

With international advanced machines imported from Italy and Spain, we can provide tiles with superior quality standard. Our company obtained the ISO9001 Quality Management System Certificate,thereby ensuring that we can supply clients with a significant quality guarantee.

Moreover,we greatly pay attention to constant technical innovation.Over the past few years,we have developed a wide range of wall tiles and floor tiles.These products are available in 300*600mm,400*800mm,300*900mm,600*600mm ,800*800mmm ...

Factory show:

FAQ:

1. What is your MOQ?

MOQ: one design one container .

Decoration design: one design 1x20’GP, also can mix color in one container.

2. What is the MOQ to use customer design carton?

MOQ: 5x20'GP. if less than this qty will charge for carton design draft fee.

We have own designers to meet your requirements.

3. What is special of your tiles?

More glossy, more shine, more 170g glaze , special technology of tile body more stable.

4. How you assure the quality?

We inspect the quality during incoming material, production process, packing and loading.

5. Where is you market ?

Our main markets are North America , South America , Asia and Middle East .

6. Do you attend oversea fairs ?

Yes, we attend the fair in Dubai, Vietnam , Algeria , Korea ,Brazil and Frankfurt etc .

7. Can you make OEM ?

Yes ,we can .

8. Where is you famous customers ?

Our customers are including The Homedepot, OBI,...

9. What price you can offer?

EXW, FOB, CFR/CIF, ect

10. Do you have quality control team and designers?

Yes, we have 10 QC and 8 designers to guarantee quality and meet your colors and styles need

11. What payment you accept?

Normally By TT, L/C also acceptable.

- Q:The floors in my house look like dark wooden planks and at each end are 2 sets of nails (the way they are supose to look). The head of the nails are about the size of maybe a dime and have the sides sanded so there are no rough edges. Can someone tell me what the name of this flooring is?

- There are two types of hardwood flooring: Engineered flooring is manufactured in a manner similar to plywood, where three or five thin sheets (plies) of wood are laminated (glued) together in a crisscross formation for strength. A top layer (veneer) of hardwood is added as a finished top layer. Engineered flooring is available as strips or planks. Strips are 3 or less in width. Planks are over 3 wide. Engineered floors are very stable and can be installed on any grade level. Although engineered wood floors are manufactured through a laminating process, they are not the same as a laminate floor. Longstrip flooring Parquet flooring Solid floors are cut from solid pieces of wood and milled to standard specifications. The flooring can be installed as planks or strips. A longstrip board is constructed of individual slats glued together end to end to form strips. The strips are then installed as tongue and groove. Parquet flooring is normally a 12x 12 square consisting of narrow strips of wood. The parquet tiles, often of varying finishes, are arranged in geometric patterns. Some wood flooring is pre-finished, others will require finishing and sealing. Many wood floors can also be refinished. A surface stain can be removed and re-stained. Penetrating stains have in essence become part of the wood and are permanent. Check the manufacturer’s specifications about refinishing. Whichever wood floor you choose, you install it using one of these methods: Nail down — attached to a wood subfloor with flooring nails. Staple down — attached to a wood subfloor with a pneumatic stapler. Glue down — engineered floors are applied to the subfloor with trowel and adhesive. Floating — tongue and groove floor planks are glued together. Rather than fastened to the subfloor, the floor rests on a pad between the floor and subfloor. as far as the wood you would need to provide more info becides Dark wooden planks

- Q:The advantages and disadvantages of solid wood flooring?

- Solid wood flooring removes moisture in the processing process, not easy to deform, and durable and non wood floors are easily affected by environment outside, decompose and release the gas expansion or deformation, no wood using a long period

- Q:What's the difference in quality!!!

- . Strengthen the floor of the test report that formaldehyde emission is low, and some floor that only 0.1 mg/L, I personally expressed doubts about this value. After the installation of the floor, we should know that the main problems in the following areas: from the drum, deformation, cracking, etc.. Laminate flooring waterproofing and moisture resistance is very poor, so it must be installed in the moisture-proof treatment. So he must install moisture-proof plastic cloth and PE mat, in order to moistureproof. In addition, the basic characteristics of the natural wood floors do not have the advantages of: sound-absorbing, anti-bacterial, rich in more refined Fen, etc., with the strengthening of the use of geothermal floor in the bedroom, I personally oppose. In the case of ground heating, the floor is prone to drum, deformation and other issues. There are a lot of domestic laminate flooring brands, but the real production line has few brands, most of them are OEM. I also borrow wood solid wood flooring. 2 solid wood flooring: wood floor has the advantages of good environmental protection, the disadvantage is maintenance trouble, fragile, easy deformation, can not be used for geothermal resource limited, solid wood floor will eventually withdraw from the market.

- Q:Shop a few years of the floor, was not a sound, and now a few steps up the sound, there is no relatively simple maintenance methods. Check Baidu, most of the answers to such questions in the post to talk about the principle of sound, as well as attention to the floor. The question now is not a new floor, so if your answer is similar, it will not trouble you. Others say that..

- Noise caused by uneven groundThere is no real or no pad pad pad, but also after the installation will occur during use, and is partial, part of floor did not fully contact with the wood keel, some places slightly convex, imbricate deformation serious floor does not have a sound, the sound of walking on the floor, the floor after installation, the floor side and adjacent floor friction, the floor will not move up and down, the installation of the floor must be according to the actual water floor rate between the relatively tight squeeze

- Q:It's a dish bean

- In fact, it is called solid wood composite floor, the performance is better than solid wood flooring and laminate flooring, the price is suitable, durable. Not only is used a lot of glue. From the point of view of environmental protection of pure wood floor is better, but I think it is more suitable for solid wood flooring.

- Q:Wooden floor can be installed for a few days to step on, solid wood and composite respectively need to hang a few days? Because of the urgent need to install curtains!!

- If it is a composite floor and multi floor, after the installation is complete, you can stay, because multi floor cash and composite floors, are free of nail products, do not use nail glue, installation can be completed using.

- Q:We are looking to put in about 600 sq of engineered hardwood floors in our house. What are some of the better brands out there. We heard Johnson hardwood is pretty good. Any thoughts?

- Bruce, Mohawk, Shaw, Bella Woods and Armstrong to name a few to get you started.Now remember each one ( and all ) of these will have a low end and a high end so shop apples to apples. As far as Johnson hard wood, I haven t heard either way with that particular one. GL

- Q:I plan to install engineered hardwood floors over a concrete slab. Should I glue it down or float it? Any other pointers for this job?

- Glued direct to the concrete will give you a better, more solid sound. It will seem to be more substantial and better quality glued down because of the solid sound. Most concrete slabs are smooth enough if you scrape up all paint over spray and drywall patch. Do test for moister. Do use the glue that the manufacture recomends, don't cheat and buy the cheap glue.

- Q:what looks the best, what is the softest for a baby to fall on?

- The best looking in my opinion is the real wood, which is what it sounds like, wood cut to fit together to make a floor. Softness, really not much difference. Engineered flooring and laminate are both factory made flooring systems that resemble wood floors. My daughter is 9 months old, and we just replaced real wood floors which were cracking and splintering, with laminate.

- Q:While laying new engineered floor boards we found some boards have a residual film after removing glue. Is there something that will remove this film without damaging the boards. We have tried wd-40, paint thinner, magic sponge.We need help floors looks baaad!! Thanks

- thinner won't hurt the floor and should remove it. Also are you sure it is not from the factory? it might be a manufacture flaw at any rate if it is glue you use thinner will do the trick

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ceramic wall tiles for bathroom & kitchen / 2016 new styles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

- Option:

- 300*600 mm

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches