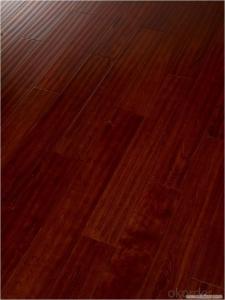

High Standard Solid Oak Flooring

- Loading Port:

- Dalian Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20'GP m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Solid Oak Flooring:

1. CE&FSC Approved

2. Custom Design

3. White oak

4. Excellent Quality and Service

5. Solid wood floor& Engineered wood floor

Product name: Solid Oak Flooring

Species |

oak |

Construction |

Solid hardwood CD Grade

|

Surface effect |

UV Lacquered, stained colour, brushed

|

Bevel | 1mm micro bevel/ can be adjusted according to requirements |

Joint System | T&G |

Moisture content | 9%-11% |

Size |

size: R.L.300-1200x125x18mm(average length 700mm) Other size selection: 57,70,83,90,120,125,130.150 180mm width

|

Certificate | CE/FSC certificate |

Packing |

white Neutral box or according to client Requirement

|

Packaging & Delivery:

Packaging Detail: 1. Carton Box 2. Carton Box on pallet 3. Wrap film packaging

Delivery Detail: About 45-60days

- Q:What is the general size of wooden floor?

- Solid wood flooring from the bottom to the surface are made of a wood processing. Common materials: wood, oak, ash, maple and cherry, with rosewood, red sandalwood and other precious species leaching paint the floor. The specification of this floor is more general: 450 mm x 60 mm x 16 mm x 750 mm x 60 mm x 16 mm x 90 mm x 16 mm x 900 mm x 90 mm x 16 mm.

- Q:I purchased engineered wood flooring, following manuf. requests, but it started to separate within a month. I pulled it all apart and GLUED it back down, removing the moisture foam barrier stuff. Now EVEN after glueing the flooring to the subfloor- it is still separating in places, not as many, but Dang! lol

- If you mop it, and it isn't nailed to the subfloor, it will absorb water and expand when wet and shrink when dry. This creates cracks as the expanding and shrinking causes it to pull away from each other.

- Q:What is the selling point

- Multilayer solid wood floor consists of plates of different species cross laminated solid wood flooring, overcomes the shortcomings of single sex, dry shrinkage and wet expansion rate is small, has good dimensional stability, and retains the natural tree wood floors and comfortable feeling. Wood flooring is divided into three layers of solid wood flooring, parquet parquet, model three, to solve the deformation defects do not wear the wood floors, and feel very comfortable, but also solve the old wood floor maintenance difficult disadvantage, represents the direction of development of the wooden floor. Its price is between solid wood flooring and laminate flooring.

- Q:Buy solid wood floor material which good?

- There are many kinds of solid wood flooring, each has its advantages and disadvantages, can be selected according to individual needs.

- Q:if laying a new wooden floor on top of existing old floor boards, which is best, engineered wood or solid wood.

- If you’re installing hardwood flooring in a lower level of your home or in an area where moisture or high (or low) humidity might be an issue, then you’re going to want to stick with engineered hardwood. On the other hand, if you are installing the new floor on an above-grade level and you want a traditional hardwood floor, then you can go ahead with solid hardwood.

- Q:I have been spending a lot of time researching and inspecting. For those who have actual experience with both these type of floors, would you please give me your take on whcih one to go for.My biggest concern keeping me away from going solid hardwood, is the scratching/denting, particularly the scratching part factor. It apperars that lamiate flooring is a lot harder and more durable to abuse.It is my house, but I do not want to live like a guest in it. Taking the shoes off, watching not to pull the chair to fast, etc.Thanks for your input.

- So you either do your best by the wood floor and accept the increased amount of scratches/dents, (pets or kids?) or do the laminate. I think laminates with grain patterns tend to be somewhat predictable with their patterns. Many engineered wood floors can be re-sanded and finished.

- Q:Solid hardwood?

- Solid hardwood is just that. Engineered is not solid wood but plywood. Eng is less expensive. The key is the quality of the finish. If the finish is good it will last longer and not wear through to the wood layer.

- Q:Wooden floor can be installed for a few days to step on, solid wood and composite respectively need to hang a few days? Because of the urgent need to install curtains!!

- If it is a solid wood floor, after installation should be placed 2-3 days is appropriate, because the wax wax on the surface of the floor has not yet fully into the solidification state, if you step up during the maintenance will leave traces.

- Q:i know engineered flooring uses adhesives and this worries me. i think hardwood installation over conrete would be complicated (we live in a condo) and we were advised to choose engineered wood. thank you!

- You can use the type of laminate that snaps together. This is installed over a pad that is rolled over the concrete. There would be no adhesive required. If you do go with the type of engineered wood that is glued together, the glue used is basically the same as yellow carpenters glue. The formula is slightly different, but for the most part it is very similar. The glue dries quickly, and once it's dry it should be sealed enough to not cause allergy issues. Hope this helps.

- Q:Can someone tell me the differences between Parawood flooringEngineered wood flooring I think I saw parawood flooring in Wickes but it looks like the backing is made of real wood. And it's around ?!5/m^2. Can it be cheaper than that? Any advice is greatly appreciated.

- Sorry no clue. But my grandpa's a general contractor. =D

1. Manufacturer Overview |

|

|---|---|

| Location | Fushun, China |

| Year Established | 2008 |

| Annual Output Value | Above US$ 5 Million |

| Main Markets | 60.00% North America 30.00% Western Europe 10.00% Domestic |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

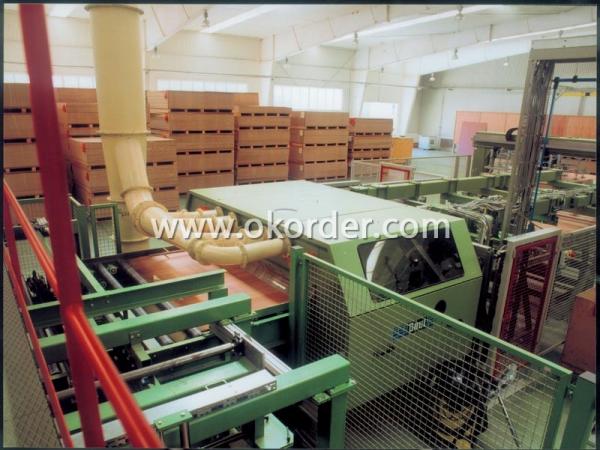

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Dalian |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 2-5 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 20,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average; Low |

Send your message to us

High Standard Solid Oak Flooring

- Loading Port:

- Dalian Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20'GP m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords