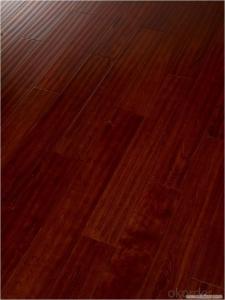

Yongsen Solid wood Floor Of The Disc Beans Red Light A Grade Pure Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 3000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Material properties

Geographical environment and climate characteristics of the material itself has a unique aesthetic and textured, dark stripes and glossy, and sapwood distinguishable. In the structure, the wood is very resistant to decay, and the wear resistance is good, and it has good weather resistance. Air dry density 0.61-0.99g/ cubic centimeters and modified wood drying after yellowish brown or dark brown, hard materials, slightly oily, stability is very good, natural resistance to rot.

2、Characteristic

1.solid wood floor, the solid wood floor, is not easy to deformation, the use of geothermal heating of the user if you must use solid wood floor, then you can use the disc beans solid wood floor.

2. disc beans solid wood floor color, made of dark wood floor is very high, but not suitable for light colored floor users.

3. disc beans solid wood flooring high hardness, impact resistance, good abrasion resistance, and occasionally hit the heavy will not have any trace.

4.Disc beans solid wood floor pattern, and therefore larger, not suitable for the pursuit of the perfect style of the user.

3、Application

Solid wood flooring is the direct processing of wood into the floor. It has the natural development of the wood texture, is a poor conductor of heat, can have the effect of warm in winter and cool in summer, comfortable foot feeling, the safe use of the characteristics is the ideal material for the bedroom, living room, study, ground decoration.

4、Parameter

The water content index refers to the solid wood floor in the sales area or just remove the unopened packaging under the condition of water rate. National standard provisions of the moisture content of solid wood floor indicator for the balance of the 7% to the sales site.

Reflect the paint board surface wear-resisting is solid wood flooring paint surface wear-resisting degree, national standards for superior quality solid wood floor paint board surface abrasion resistance index is less than or equal to 0.08g/100r; first-class product is less than or equal to 0.10g/100r; qualified product is less than or equal to 0.15g/100r.

Reflect the adhesion of the paint to paint the adhesion strength of solid wood flooring, national standard superior quality solid wood floor paint film adhesion index 0 to 1 level; first-class product is less than or equal to 2; qualified product is less than or equal to 3.

Film hardness is a reflection of the strength of the surface film of solid wood flooring, the provisions of national standards of superior quality solid wood floor paint film hardness index for 2h grade; first-class and qualified products is greater than or equal to H.

5、Reference pictures

- Q:We are trying to decide between two products based on their different application. 1. Home Legend Maple Durham click-lock to be installed floating (with moisture barrier and padding)2. Shaw Brass Maple to be glued (using new one step non-toxic glue) Our slab is not perfect. We are doing a large 700 sq ft room including foyer, kitchen, hallway, and large living area. I do not like the hollow sound laminate makes and want to avoid this. Should we glue the floor or install floating? We will be installing ourselves (husband works in masonry).

- Last summer I installed about 1200 ft2 of floating wood floor in 5 different places in the house. After a year everything is looking good and there are no issues with floor. I was careful to make sure the floor had room for expansion and there are no humps or shrinkage openings. Neighbor across the street has a few humps in his glued down version. When you walk across the floor, there is a slightly hollow sound but I have had this in nail down floors. Where the floor slab had some dips the sound is a little more hollow. One of the reasons that I decided to go with the floater is that I could work at my own pace and not have to brace the floor so that it did not expand overnight with the glued version. I did a nail down 1300 ft2 in a previous home and it was solid with 15 pound tar paper under it. That floor had the hardwood click to it. It was much harder to install than this floater. In looking at the fact that the flooring is not all exactly straight and perfect and that I could not do 700 ft2 in a day and did not want to brace, I would probably go with the floater again. You still need a vapor barrier under the glued floor to prevent moisture absorption through the slab.

- Q:How thick is the layer below the wood floor

- Clean light composite wood flooring tips: use cloth dipped in clean water wipe directly on the floor, or the washing water is evenly sprayed on the wooden floor (not too much), 5 minutes with dry dishcloth, the floor will be clean a lot. Special stains cleaning: grease, paint, printing ink can be used special stains to wipe oil; blood, juice, wine, beer and other stains with a damp cloth or wiping the floor cleaning cloth dipped in the amount of wax; and chewing gum, with ice on it for a while, the frozen contraction, then gently sweep, reoccupy a wet cloth or wiping the floor cleaning cloth dipped in the amount of. Do not use strong acid and alkali liquid to clean the compound wood floor.

- Q:The floor, the floor to the factory maintenance time, the new floor miaojie special oil, was trying to sell me, too expensive, not to buy. Want to go to the supermarket to buy a little, but do not know what brand is good, to understand the MM point of view ah, thank you!

- If you do not accidentally pour water or omission of water on the ground, it is necessary to wipe dry with a soft cloth. After cleaning, can not be directly exposed to the sun or baking with electric stove, so as not to dry too fast, dry floor. Animal urine with acid-base, when used to clean up.

- Q:What is the preferred method of installing an engineered wood floor over a concrete slab? Float or glue & why?

- It depends what you mean with engineered wood floor. Normally that term means that the planks have tongue and groove. If you have a massive wood floor with tongue and groove you should always glue it to the floor with an elastic glue. Anoter option is to lay an underconstruction with peaces of wood 40cm away from each other across the room. Then with 90° you can screw the floor to the unterconstruction through the tongue and groove.

- Q:How to protect the wood floor?

- Strengthen floor maintenance easily fall into two errors:First, excessive maintenance, such as waxing, or repeated a day with a very wet mop mopping the floor, are wrong;Two is to ignore the maintenance, long time is not clean, do not pay attention to ventilation, the situation is not timely repair, such as the drum after a long time does not repair, it is easy to cause the edge can not be repaired, etc.. In view of this situation, as long as the understanding of the basic knowledge of the use of the floor, laminate flooring maintenance is not trouble. In daily life, pay attention to the details, you can bring the floor of the consumer long-term stability

- Q:I have a very old home that is on blocks. It was built with a 1 x 3 pine plank floor with no sub-floor. I recently remodeled and installed felt paper over the old planks then a polyfoam underlayment pad with an engineered wood floor on top. After several weeks the original wood plank floor began to cup and buckle underneath from moisture. I have now removed the expensive new flooring and am at a loss of what underlayment to use. I suspect that my problem was either evaporation from under the house or condensation from the polyfoam pad. Any suggestions?

- You need to install a good plywood sub floor. Your problem was not with the underlayment as it was on top of the pine plank sub floor that buckled. Use a good 3/4 plywood subfloor with clips (to hold it together). You may be able to put it over the pine planks but it must be layed so that the seams run at a 45 degree angle to the seams of the pine planks. You would then, ideally, want the seams of the hardwood run at a 45 to the sub floor. That will make it very stable. If its a floating system use a good underlayment fabric as well.

- Q:what's a good brand for hardwood floor, laminate and engineering wood?

- Bruce is a good brand of flooring products, and they carry solid wood too. They carry a variety of prefinished flooring product, that would save you a lot of time on installation. Pergo is gaining recognition as a laminated floor manufacturer, but honestly, Ive seen other product at Lowe's that was just as good, and cost less...

- Q:How to do under the solid wood floor

- Water reaction1 floor joint edge deformation.2 baseboard deformation.

- Q:I'm installing an engineered wood floor in a second floor bedroom. Currently has a plywood subfloor in fairly decent shape. However there are some voids and gaps in the subfloor. What product should be used to fill these areas? Would ceramic tile adhesive work? Do the gaps between plywood sheets (maybe 1/8 gap) need to be taped and filled?Thanks?

- You shouldn't have to worry about gaps that small. just make sure floor is pretty level.

- Q:hardwood flooring is not so popular in my country but I like it , I went to store today and found 3 strip engineered wood flooring ..will it look as good as the plank wood flooring ? or it'll look cheaper ?

- Although some of these look better than others , you ll be able to tell it comes in a 3 strip pc. You ll be able to see the seams a bit. Some do go together better than others and are not as noticeable but again some look real bad. The over all top look plays a part in the final look also. But the bottom line is that it won t look quite as good as the single stripe. GL

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Yongsen Solid wood Floor Of The Disc Beans Red Light A Grade Pure Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 3000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords