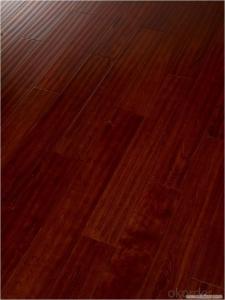

CE Cetified Laminate Flooring CM-001

- Loading Port:

- ShanghaiPort

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2000 m² m²

- Supply Capability:

- 20000 m² m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Laminate Flooring

1)Core:HDF green or brown

2)Thickness:7,8,12mm

3)HDF Density 850-920kg/CBM

4)ISO9001,ISO14001,CE,SGS,E1

We are a private export manufacturer of Superior Laminate Flooring founded in 2001.Our aim is Customer's Satisfication to keep long-term business!In order to control good quality,we establish professional lab to test products to European Standard EN13329.All MEIQI members will do efforts to develop High-grade laminate flooring,best service,and fast shpiment to build best cooperation with all customers!

laminate flooring

1)Thickness:7mm,8.3mm,12.3mm

2)Surface:Crystal Surface,Feather Surface,Glossy Surface,S/M/L Embossed Surface,Semi-Glossy Surface,Hand Scratched Surface,Pine Surface,Synchronized Surface,Registered Embossed Surface.

3)Color:Oak,maple,cherry,beech,walnut,ect

4)Basic material:HDF green or brown Density 850-920KG/CBM

5)Click system:Double click,ARC(Half round click)

6)Size and Package

1218*197*8.3mm 60ctns/pallet,20pallet/20'C=2880.00SQM(with pallet)

1350ctns/20'C=3240.00SQM(without pallet)

1215*196*8.3mm 60ctns/pallet,20pallet/20'C=2857.68SQM(with pallet)

1350ctns/20'C=3214.89SQM(without pallet)

808*130*12mm 32ctns/pallet,28pallet/20'C=1882.32SQM(with pallet)

1010ctns/20'C=2121.81SQM(without pallet)

1215*196*12mm 60ctns/pallet,20pallet/20'C=2004.00SQM(with pallet)

1350ctns/20'C=2254.50SQM(without pallet)

810*148*12.3mm 32ctns/pallet,28pallet/20'C=2148.25SQM(with pallet)

1010ctns/20'C=2421.58SQM(without pallet)

400*800*12.3mm 39ctns/pallet,28pallet/20'C=2096.94SQM(with pallet)

1200ctns/20'C=2304.00SQM

7)Standard:ISO9001,ISO14001,CE,E1,SGS

- Q:And where's the best place to shop for either hardwood floor in Toronto?

- All depends on the exact installation method your doing. Not all engineered wood is of the click and lock variety and can be stapled ( special air driven stapler that you can rent) or glued down. Solid wood needs to also be nailed or stapled to install. Solid wood cannot be glued down. So choose your installation method. But between the 2, I prefer engineered wood. Fits together easier, lighter weight and much faster if your stapling it down. Gluing is easy but messy. But your solid wood will be a bit better in the long haul. As to were to get it, I prefer the small flooring stores to get more personalized service. You will pay less at times in the big box stores, but not always, check both places. Any questions you can e mail me through my avatar. GL

- Q:whats the different between this two type of wood for flooring??i don't really understand ... as i know hardwood was cut from timber and engineered wood was like few wood plank stack together...is that correct??which one better for flooring?? as in maintenance or pricewhich one worth??

- Engineered wood flooring is essentially plywood with a hardwood veneer for the top layer. It comes pre-finished, is stable, and easy to install. The thickness of the veneer layer can vary. Usually, there's enough so that the floor can be sanded and refinished....one time. Hardwood flooring is solid wood. It comes both pre-finished or unfinished. Being solid, it can be sanded and refinished many times. Installation is a bit more difficult than engineered wood. Some of the pieces develop a slight warp and it takes a lot of work to force them into a tight fit.

- Q:The floors seem very dull although I have been told the finish should last 20 years. I have cleaned and once dry it is still dull. I have been told by a floor guy that I cannot buff it up because it is not real wood.

- nothing, it was engineered that way

- Q:Which is better and why? Which is better for resale-ability? I realize they both have pros and cons, but - we're looking at it for the 1st floor - above ground, and not in the basement (no moisture problems).

- pure hard wood floors around 5 time the price of engineered flooring... if you were intending and staying there, use pure wood, looks better out last engineered floor 10 time much longer..... from a buyer point of view engineered flooring looks new, and fresh ,and this is what you want the buyers to see right? but engineered floor is a pain to lift up if you chip.spill paint on it. burn it.... the list goes on, on the other hand , pure wood can be sanded, painted and removed very easily so there you have my thoughts !! if you selling pick the plastic wood, if your staying use real wood .

- Q:What is the preferred method of installing an engineered wood floor over a concrete slab? Float or glue & why?

- Floating a floor is easier to install than a glue down especially for a less experienced person or a DIY. There are less harmful fumes to breath when floating a floor. Floating flooring has more give and so the sub floor can have more unevenness/small dips compared to a glue down. Glue down will have a more solid feel when walking on it, and floating will have more give. Some people are bothered by a slight hollow sound when walking on a floating floor. The sound or give do not bother me, personally. Also, check with the store...some actually require a glue down.

- Q:I am building a new house, and I have two large dogs. The house is a $200k smaller home with very nice appliances, granite counter tops, etc. Anyways, I have two large dogs who have scratched up the hardwood(not terribly) in my condo, so I am thinking about putting in the engineered flooring. I have been to lumber wholesalers, and it isn't really much cheaper than hardwood, but it is my understanding that it is much more durable. It seems to look and feel like hardwood, and I have heard that the engineered floors have come a long way, but I'm paranoid that it's going to look cheap. Would putting in the engineered flooring be a mistake?

- Engineered woods have their place but in comparison to real hard wood they don t come as close. If fact if either flooring was and aluminum oxide finish , both are very hard to refinish so a real hard wood you can resand a bit more to be able to refinish them. Aluminum Oxide is one of the toughest finishes in a pre finished hard wood.Not available in finished on site applications. You have to nice of home to put in a good quality laminate which will hold up to the dogs. Where the cheap laminates won t.. Get the hardwood and think maybe of getting a harder species with multiple coats or urethane if your doing finished on site. Any questions you can e mail me through my avatar..GL

- Q:Was it as difficult as all the hype ? What was the hardest part?Estimates for having done are 8-10K, just can't pay that.

- Yes. If you've installed floors before you'll know, but for one thing you have to use leveling concrete to make sure the surface is level. Then you've got to be sure to spread out the wood evenly as you're installing it to give it tht more natural look. Make sure that no seams are lined up or at least 6 apart within two rows.Working with a trowel an polurethane glue takes some practice, too. When you get to the end pieces piece backwards and mark upside down w/a pencil to get the right size before you cut. Leave at least a 1/4 gap on the sides. You will also need ratcheting floor clamps and blue tape to hold everything in place while the glue cures.Also,you will need shims and a bar(I don'tknow how it's called) that you can pound backwards on the flooring to get it in place. Put weight on any loose spots te hold down and if any are loose afterward, you can inject filler at the end, but be sure to level everything. I think the hardest part would be leveling, getting the rythem, and using the glue.

- Q:Some solid wood floor light, which is good, how to separate

- The floor is mainly to see the stability, than the major wood species in the impact resistance wear better, but there are many there will be little paint adhesion, poor toughness (Yi Kailie) etc., and the proportion of small plates most paint with good adhesion and good toughness, but because of low density and fiber hole, shrinkage and swelling rate some big.

- Q:Contractor has quoted me a price of $5.50 / sq. foot for materials (engineered maple), and $4.50 / sq. foot for glue-down installation. I thought since he's doing our whole house (2000 sq feet) he'd give us a cheaper price for the installation. Do you think $1.50 / sq. foot is reasonable to ask?

- Then try to get a quoter closer to the $3.25, saying that getting work done depends a lot on the availability of local labor, not having many installers in your area will cost you more sad to say. I hope this helps

- Q:Does buffing engined hardwood floors really work? Could it take out scratches and slight water damage?

- Engineered flooring can be treated just like regular hardwood flooring.... UP TO A POINT. Engineered flooring is a product made up of a thin veneer of the preferred wood applied to a plywood backing or base. You can do anything to this veneer that you would do to a solid hardwood, BUT you will be limited to how aggressive and how many times you can do it by the thickness of the veneer. You will eventually wear though the veneer and into the substrate. So unless the water damage has delaminated the flooring, slight sanding and buffing will help remove the damage provided you do not go too far

1. Manufacturer Overview |

|

|---|---|

| Location | Fushun, China |

| Year Established | 2008 |

| Annual Output Value | Above US$ 5 Million |

| Main Markets | 60.00% North America 30.00% Western Europe 10.00% Domestic |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Dalian |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 2-5 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 20,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average; Low |

Send your message to us

CE Cetified Laminate Flooring CM-001

- Loading Port:

- ShanghaiPort

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2000 m² m²

- Supply Capability:

- 20000 m² m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords