Aluminum Foil with PET and LLDPE for Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

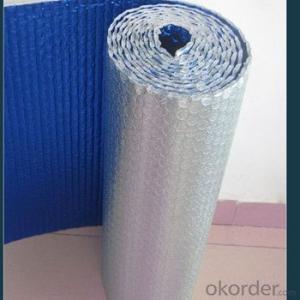

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q:I've never been a salesman. My company wants me to do business, but I don't know how to start doing it. I just got into the company soon. I don't know about the film yet. I don't know where to start.

- Then you start with phone sales, and look for protective coatings on the Internet. Call, ask, sample, try, and then visit.In short, the business is not accomplished overnight, the long-term accumulation of experience, experience in communication with people, product experience, industry experience.

- Q:What does it mean that a protective film is anti-blue-ray?

- Anti-blue-ray protective film can weaken the blue ray of the screen. It would not be so dazzling that it can ease visual fatigue. Blue ray is the light emitted LED screen. It's a component of artificial light. It's bad to the eyes looking at the screen for a long time.

- Q:How to remove the protective film on painted iron plate without damaging the paint? The film is very thin.

- Blowing it with electric hair drier to make it easy to peel off.

- Q:Is there any way to tear off the protective film on furniture that is used for too long?

- Blow the film with electric hair drier for half an hour. When the film gets soft, you can gently pull it by hands to tear off the whole film.

- Q:What kind of protective film can cover the matte surface?

- The glue of the film must be thick, as least 0.03mm.

- Q:What's the use of PET protective film?

- Product application: suitable for panel protection, such as stainless steel, aluminum plate, nameplate, and notebook computer casing and display screen, mobile phoneThe screen support, such as baking paint, plastic film, etc..Product color: white transparent, milk white, blue, black and so on. (can also be customized according to customer requirements)

- Q:There are several labels on the toughened film, which are the protective films that need to be torn off

- I hope my answer will help you. If you have any questions, please feel free to ask questions. Thank you!

- Q:How to clean the glue marks left by the protective film on the stainless steel plate of the light in the living room?

- Alcohol works.

- Q:Use of protective film for decoration

- Through the use of protective film to protect floors and doors and other products, can effectively prevent scratches or crash floor tiles and doors, reducing the risk of unnecessary losses during renovation.Hope to adopt

- Q:The PET protective film appears to be a solution to the problem

- PET protective film in use after a period of time will be two wings, the main reason for this phenomenon is a protective film on the protection and profiles in the paste process, the degree of tension is large, in the post after, in high temperature environment, the retraction phenomenon is not necessary,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil with PET and LLDPE for Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords