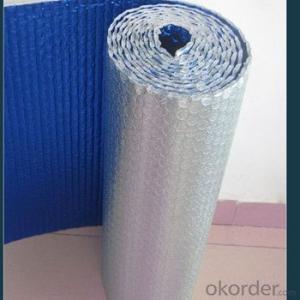

Aluminum Foil Facing Mylar for Bubble Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q:PVC protective film and weaved cloth, which is better to protect floor?

- You'd better use cotton PVC film. But it's expensive. Using ordinary gypsum board is also okay. You can cover the edges of the board with tape.Its cost performance is high. And it's really durable.

- Q:How to get rid of the Kraft protective film on the plastic plate?

- Heat the plastic plate at first (Baking it on fire. Note not to put it too close to the fire, otherwise the plate will be out of shape; Or putting it on heating radiator for a while; Of course if it's summer, you can just put it under the sun.). And then slowly pick up one cornor with your nails and tear it off. Roll it while tearing it. You can grasp the film when you roll it for 6 or 7 times. And then tear off the whole film. The key point is patience. If there's a part where the glue is too sticky, stop pulling and dig it with your nails. Remember not to pull it too hard.

- Q:How to use super light clay to make transparent protective film?

- As for clay, especially the soft type, if you apply protective oil before it's complete dry, indentations may remain at the last stage of pressing.

- Q:What's the use of PET protective film?

- PET protective film refers to the protection of PET material paste, as we usually see the beverage bottle is PET material, can be used to protect the screen, mobile phones, cameras, etc., to avoid scratches, to protect the effect.

- Q:Use of protective film for decoration

- Entrance door protectionAll kinds of decoration materials and a variety of architectural decoration into garbage clean-up, will go through a door, these items in the handling process, the probability of collision, friction and Ruhumen greatly increased, therefore, the first need to protect product place is our entry door. Recommendation: all doors should be protected before the decoration starts until the furniture comes into play! For this, you can use the finished protective film to wrap the door.

- Q:What kind of printing press is needed to cover decorative protective film?

- During the processing of protective film, film mulching machine must be used in film mulching. And gravure rotary press can be used in printing the protective film.

- Q:What kinds of materials is the protective film made from?

- According to material quality, it can be made from common materials including PET, OPP (PP), PVC and PE.

- Q:What are the differences between PE release film and PE protective film?

- The adhesives used in PE release films are release agents which the property that make it impossible to stick sticky objects to it. It's mainly used on the separation of double-sided adhesive tapes and that of label and its backing paper. The adhesive used in PE protective films is glue of low adhesion which makes the film adhesive though not very sticky. And the film is used on surface protection of materials.

- Q:How to prevent the protective film from damage and the stainless steel from marks when drawing the steel?

- The surface quality of drawing dies of stainless steel is highly required. Rough surface can decrease friction and increase the property of adhesive resistance. Therefore, after the grinding processing, the more important work is to remove the processing marks left on the drawing dies. However, few people know the importance of the grinding and polishing processes when making dies. Throughout the whole process, the proportion of grinding and polishing processes should reach one third because the appearance quality of stainless steel products,to a large extent, is determined by the grinding and polishing techniques of making dies. The rougher the surface of dies is, the less it needs re-grinding. And the life of the dies also extends accordingly. If the surface of dies is not well grinded and polished, the marks on the drawn products will be clear. Although there's something to do with the fact that drawing stainless steel can easily cause seizing tumour, too. And to polish these marks takes time and the result is not good. Thus we should pay more attention to the grinding and polishing processes. Only when the surface processing precision of dies improves, can the marks decrease and the life of dies extend. In recent years, various new polishing techniques and polishing tools have arised at home. New processes and equipments such as ultrasonic polishing, electropolishing, abrasive jet and extrusion honing have been developed.

- Q:Is PET film anti-static?

- We have developed a kind of inner-added transparent raw material for anti-static film that can be used in curtain coating, film blowing, calendering, extrusion, extruded profiles and tubular products, injection molding as well as co-extrusion. The tranparency of the finished products is high. The anti-static value reaches 10 to the power of 9. And there's no educt.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil Facing Mylar for Bubble Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords