Stainless Steel Fermenter With CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

Processing: Storage Tank, cutting-rolling-welding-polishing-assembling-testing-warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: bright tank, KB-006

Processing Types: Alcohol

Voltage: 380V, 50HZ

Certification: B&V; CE

Image:

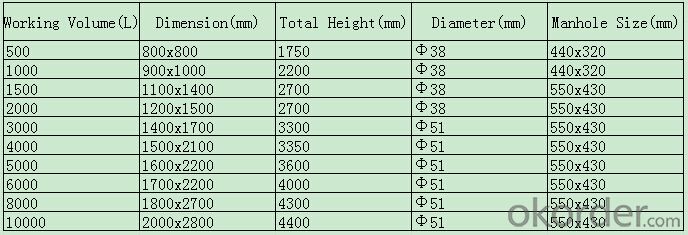

Specifications

Technical Data:

- Q:Explain the effect of magnetic scale to the boiler tube?

- I think you are talking about the formation of magnetite (Fe3O4). A layer of magnetite is considered to be a protective layer on the tube formed by the corrosion of a small layer of the base metal (tube wall). The layer of magnetite is desirable and is actually a controlled corrosion which degrades the tube at a slow and uniform rate. Boilers are designed for a corrosion allowance and the loss of tube wall thickness due to the magnetite layer is expected. Water chemistry is maintained to protect the magnetite layer to prevent other forms of attack and corrosion. Other forms of scale due to salts form buildup on the tube wall. Any scale buildup causes the temperature difference across the tube wall to increase. If an entire boiler system was scaled up, to maintain the same thermal output, the temperature on the fire side of the tube would have to be increased to maintain the same temp. on the water side of the tube. Eventually, tubes will fail due to the extreme temps.

- Q:What is the concept of "hydrophobic" and "condensate" in the boiler?

- Boiler in the normal operation of its steam pipeline inside the flow of steam, steam is absorbed by the water vaporization, when the boiler outage, the pipeline will be hot inside the steam condensed into water, it formed what you said

- Q:In boiler,how drum level can be measured by differential pressure transmitter.How can we give minimum and maximum value.Explain with example

- - in the drum : there are two pip , 1 no. connected to top 1 no. connected to bttom of drume. - in the PT : there are two pine , 1 no. high ( H ) 1no. low ( L ). - to measure the level : connecte the top pip in the drum to the pin L in PT

- Q:The role of the boiler

- 3, according to the use of points: life boilers, industrial boilers, power boilers, marine boilers

- Q:I want to build a monotube boiler. I have plenty of muffler pipe in the garage, and its thickness complies with the ASME formulas for the design pressure, but the type of steel may not be boiler type. What do you think?

- I would think muffler material would work for a boiler since it sees fairly hot temperatures when in service. To me the question is what pressure will you be operating at and what safety devices will you have to prevent over pressure. If the tube was to fail, it is likely to split and not explode. Is the muffler pipe seamless or erw? If erw then you need to be concerned about the quality of the welded joint. I would do a serious pressure test before I used it for a boiler. Probably at least twice the operating pressure.

- Q:What is the net efficiency of the boiler

- Net efficiency is to put other energy consumption as input heat, as a base to calculate.

- Q:Hot water pipe to boiler was cracked and fixed but the radiators weren't bled. The boiler and house radiators worked fine apart from the upstairs ones only getting hot at the bottom. I bled the upstairs radiators as normal and re-pressured the boiler and turned the system on. The pressure was fine until the heating was turned off and then as the radiators got cooler the pressure dropped and finally got to 0. Re-pressured the boiler again and left the heating this time and the pressure stayed the same, turned the heating on the everything worked fine until I turned the heating off and the same thing happened with the pressure (as the radiators got cooler the pressure dropped slowly down to 0). I have noticed now as well that the overflow pipe outside for the boiler has a very slow drip.

- The pressure relief valve is failing, and needs replacing. It is the valve that the overflow pipe is connected to. Priced at anything between ?45/65 depending on the type of boiler.

- Q:i have an old fireplace with back boiler, and i want to upgrade it and take the back boiler out. I've been told the boiler from the bathroom will need moving (i dont know why) to adifferent location within the house. How much will it cost to upgrade the fireplace and to buy and install a new boiler?

- taking the old back boiler out can be a dirty, dusty job, it not only involves a plumber but also a builder. I cant help you with the costs you will have to get a couple of estimates. The boiler in the bathroom is a different matter. This is not allowed under the gas regulations unless it is a room sealed unit (balanced flue). The moisture laden air in a bathroom can interfere with the burning gas in an open flued boiler and produce carbon monoxide. I suspect you have an open flued boiler. However a new room sealed boiler could possibly be installed there, it would depend upon the manufacturers instructions, for example how far would the flue be from an openable window, plus other conditions. a CORGI installer would have to check it out. Most modern condensing combi boilers are room sealed, and they vary greatly in price. Get a few estimates, and don't take the first guy that comes along

- Q:what are smoke tube boiler ?detail working required?

- Same as a fire tube boiler. There are fire tube and water tube boilers. I bet wikipedia has articles on this.

- Q:what is the difference between waste heat recovery boiler and waste heat recovery in boiler?

- A waste heat recovery boiler is a boiler that specifically does only that function, there is waste heat from a process and the boiler is added to turn that heat into steam. There is no actual furnace or firing section in the boiler. An example is what is called a heat recovery steam generator that is put on the output of a combustion turbine. Have both is called a combined cycle generating unit. A boiler that also recovers heat has a furnace section in it, fuel is burned in the boiler but it also has additional heat transfer equipment added to it to extract the energy that would have gone up the stack. This heat may be used in another process or may be used to make the boiler more efficient by preheating the combustion air or feedwater.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Fermenter With CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords