Pleated PTFE membrane filter cartridges for air or solvents

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hydrophobic Pleated PTFE membrane filter cartridges for sterile air or solvents

PTFE Filter Cartridge

PTFE Filter isa sterilizing grade air & gas filter that utilize naturally hydrophobic

material provides effective retention of microbes and particles in air/gas.

Features

l Inherently hydrophobicity.

l High flow rates at low differential pressures.

l High steam cycle lifetimes and thermal strength.

l Reliable separation of microorganisms and bacteriophage.

Materials

l Media Layer: Hydrophobic PTFE

l Support Layer: Polypropylene

l End Caps/Core/Cage: Polypropylene

l O-Rings/Gaskets: Silicon, EPDM, Viton, Teflon

l Internal Adaptor Ring: PS / Stainless Steel 304

Operating Conditions

Max. running temperature | ≤80 ℃ |

Max. Allowable Differential Pressure | ≤5Bar(20℃) |

≤2Bar(80℃) | |

Inline Steaming Sterilize | 121 ℃, 30min@max differential Pressure of 0.05MPa up to 25 times |

Food and Biological Safety

Extractables | <30mg per 10 inch |

Endotoxins | <0.25EU/mL |

Ordering Information

PTFE | Micro Rating | Connection | Length | Gasket |

01=0.1μm | 0=222+Flat | 10=10 inch | S=Silicon | |

02=0.22μm | 5=222+Spear | 20=20 inch | E=EPDM | |

04=0.45μm | 7=226+Spear | 30=30 inch | V=Viton | |

10=1μm | F=DOE | 40=40 inch | F=PFA |

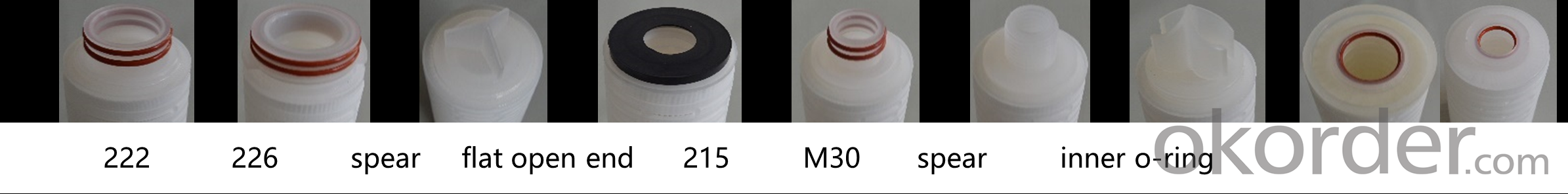

Connection details

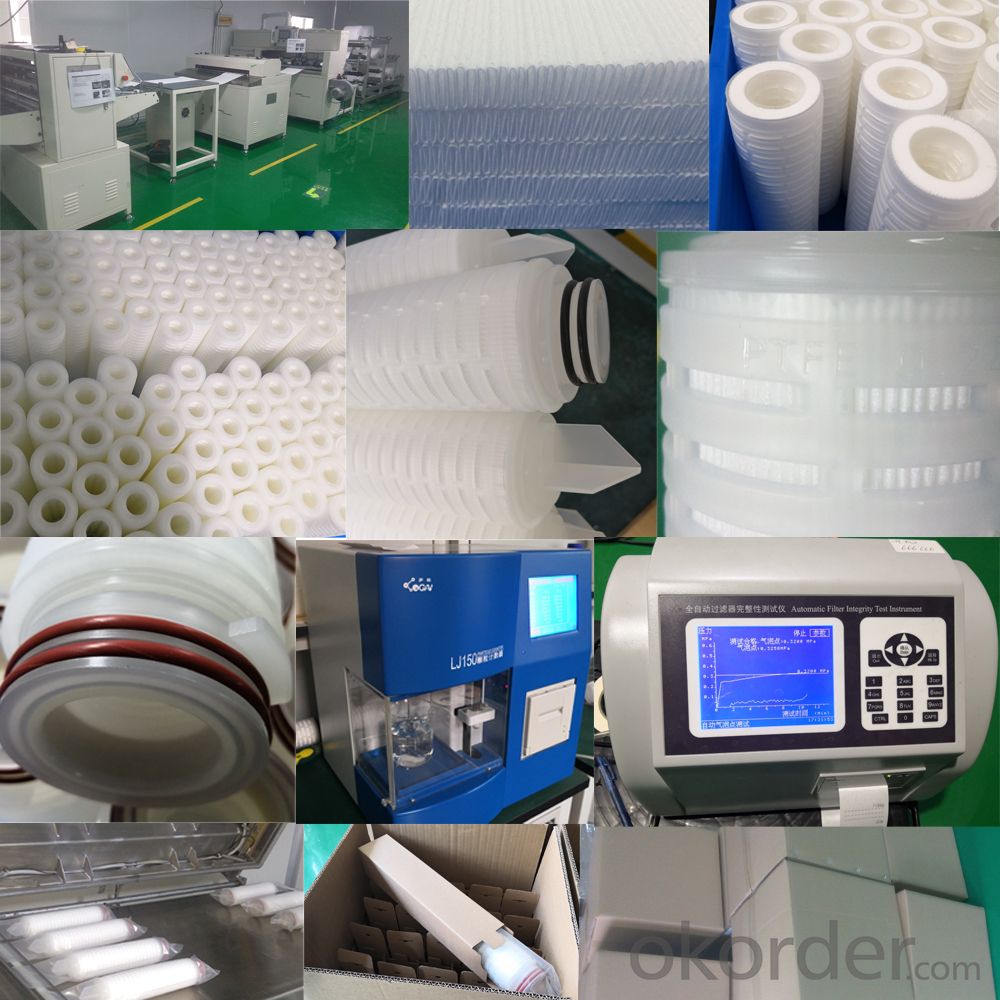

Process

- Q:Does Honeywell have an industrial prefilter?

- Such as industrial waste water, filtration of circulating water, regeneration of emulsion, waste oil filtration treatment, continuous casting water system in metallurgical industry, blast furnace water system,

- Q:What are the famous water treatment plants in China?

- Main uses: power plants, factories, high and low pressure boilers, air conditioning, cold storage and other recycling water. Microelectronic products are produced with high purity water, semiconductor, display tubes, high purity water, computer circuit boards and other integrated circuit water, solar cells, dry batteries.

- Q:Classification of filters

- Negative pressure is formed at the outlet of the filtrate as a driving force of filtration. The absolute pressure of the operation vacuum of the industrial vacuum filter is (2.5 ~ 8) * 105 PA. When filtering, the temperature of the suspension should be lower than the evaporating temperature of the filtrate under the operating vacuum.

- Q:Application range of quartz sand filter

- Also used in the water reuse system, swimming pool, circulating water treatment system depth filtration. It also has good removal effect for suspended solids in industrial wastewater.

- Q:What is the principle of industrial dust collector?

- With repeated attachment to the outer surface of the bag of powder, powder thickening layer continuously, industrial bag dust collector resistance value increases; pulse valve diaphragm instruction about submerged pulse valve open, compressed air in the air bag through, if there is no dust or small to a certain extent. Mechanical cleaning work will stop working.

- Q:What is the scale of industrial circulating water system and what method or equipment is used to remove scale?

- Industrial circulating water system in scale, application of what methods or equipment cleaning in industrial circulating cooling water system for open cycle system (such as counterflow and crossflow cooling tower), full contact with air and water cooling tower.

- Q:What are the requirements of industrial dust collector for filter bag?

- Hello, industrial dust collector bag has high temperature resistant, corrosion resistance, low water absorption,

- Q:What about the cooling performance of industrial refrigerators?

- dry filter part blocked. Blocking the filter will reduce the refrigerant supply, the water cooler evaporation temperature is low, the evaporator fin will be frosted, refrigerant evaporation, flow into the back pipe and compressor continue to evaporate.

- Q:What about the quality of industrial filters, filter cores and filter bags produced by fly wave filtration?

- The flying development tide of precision filtering system with independent intellectual property rights, has won the domestic and foreign patents, and bear the national standard "general specification for liquid filtration filter" work, get the industry recognized.

- Q:The features of paper tape filter and disc vacuum filter?

- gravity type paper tape filter: flat screen drum type paper tape filter, filter paper tape, arc net type paper tape filter, frame filter paper tape such belong to gravity type paper tape filter within the scope of filtration depends on the gravity of liquid permeability formation of filter cloth

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pleated PTFE membrane filter cartridges for air or solvents

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products