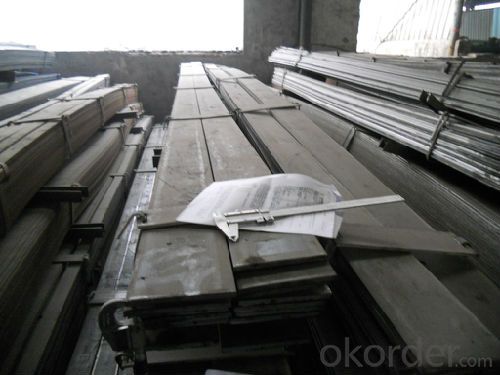

Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Flat Steel

1.Thickness:1.5mm-14mm

2.Width:10mm-1010mm

3.Grade:Q235, Q345, A36

3.Factory producing, guaranteed material

| Flat Steel | |||

Width (mm) | Thickness (mm) | Length (m) | Theoretical Weight (kg/m) |

| 20 | 2.0 | 6/9/12 | 0.31 |

| 20 | 2.5 | 6/9/12 | 0.39 |

| 20 | 2.75 | 6/9/12 | 0.43 |

| 25 | 2.5 | 6/9/12 | 0.49 |

| 25 | 3.75 | 6/9/12 | 0.74 |

| 30 | 2.5 | 6/9/12 | 0.59 |

| 30 | 3.5 | 6/9/12 | 0.82 |

| 30 | 9.75 | 6/9/12 | 2.30 |

| 40 | 3.5 | 6/9/12 | 1.10 |

| 40 | 4.75 | 6/9/12 | 1.50 |

| 40 | 11.75 | 6/9/12 | 3.69 |

| 50 | 2.75 | 6/9/12 | 1.08 |

| 50 | 4.5 | 6/9/12 | 1.77 |

| 50 | 9.75 | 6/9/12 | 3.83 |

| 60 | 5.5 | 6/9/12 | 2.60 |

| 60 | 7.5 | 6/9/12 | 3.53 |

| 60 | 11.5 | 6/9/12 | 5.42 |

| 80 | 5.5 | 6/9/12 | 3.45 |

| 80 | 7.5 | 6/9/12 | 4.71 |

| 80 | 11.75 | 6/9/12 | 7.38 |

| 100 | 3.25 | 6/9/12 | 2.55 |

| 100 | 4.75 | 6/9/12 | 3.73 |

| 100 | 7.5 | 6/9/12 | 5.89 |

| 120 | 9.75 | 6/9/12 | 9.18 |

| 120 | 11.75 | 6/9/12 | 11.07 |

| 150 | 9.75 | 6/9/12 | 11.48 |

| 150 | 11.5 | 6/9/12 | 13.54 |

| 150 | 13.5 | 6/9/12 | 15.90 |

| 160 | 11.75 | 6/9/12 | 14.76 |

| 200 | 9.5 | 6/9/12 | 14.92 |

| 250 | 5.75 | 6/9/12 | 11.28 |

| 340 | 7.75 | 6/9/12 | 20.68 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:Are steel flat bars commonly used in the construction of residential buildings?

- Residential buildings often incorporate steel flat bars as they offer numerous advantages. Firstly, their exceptional strength and durability provide structural stability and support. With a high strength-to-weight ratio, they can bear heavy loads without burdening the structure. Consequently, they are ideal for constructing load-bearing walls, beams, and columns. Furthermore, steel flat bars are highly versatile and can be easily customized to meet specific design requirements. They can be cut, drilled, and welded to create various shapes and sizes, enabling architects and builders to achieve the desired structural configuration. Additionally, their excellent resistance to fire, corrosion, and weathering ensures the longevity and safety of the building. Moreover, steel flat bars are a cost-effective choice compared to other construction materials. They are readily available and can be purchased in bulk at a reasonable price. Furthermore, steel is a sustainable and recyclable material, aligning with the increasing focus on eco-friendly construction practices. In conclusion, the strength, versatility, durability, and cost-effectiveness of steel flat bars make them a popular choice in residential construction. They play a crucial role in providing structural support and stability, making them highly favored by architects, engineers, and builders in the construction industry.

- Q:Cold rolled flat steel standard. What is cold rolled flat steel?

- Section steel is one of the four major steel products (plate, tube, mould, wire). According to the section shape, the section steel is divided into simple section steel and complex section steel (deformed steel). The former refers to the steel, round steel, flat steel, angle steel, six angle steel; the latter refers to the I-beam, channel steel, steel, steel, steel frame bending etc..

- Q:Are steel flat bars heat-treatable?

- Yes, steel flat bars can be heat-treated. Heat treatment is a process used to alter the properties of steel by subjecting it to specific temperature conditions. This process can be used to increase the hardness, strength, and durability of the steel. Heat treatment involves heating the steel to a specific temperature, holding it at that temperature for a certain period of time, and then cooling it at a controlled rate. By carefully controlling the heating and cooling cycles, the structure and properties of the steel can be modified. This allows steel flat bars to be customized to meet specific requirements for different applications.

- Q:What are the different specifications for steel flat bars?

- Steel flat bars can have different specifications depending on their dimensions, such as width, thickness, and length. They can vary in width, ranging from 1/8 inch to several inches, and thickness, ranging from 1/8 inch to 1 inch or more. Lengths can also vary, commonly found in standard sizes of 8, 10, or 20 feet, but can be customized as well. Additionally, steel flat bars can have different grades or types of steel, such as carbon steel or stainless steel, which can affect their strength and corrosion resistance properties.

- Q:Are steel flat bars suitable for making electrical machinery or equipment?

- Depending on specific requirements and application, steel flat bars can be used for electrical machinery or equipment. Steel provides several benefits, including high strength, durability, and excellent conductivity, which are advantageous for electrical applications. However, it is important to consider factors such as electrical conductivity, magnetic properties, and corrosion resistance when choosing the right steel flat bars for electrical machinery. In certain situations, copper or aluminum may be preferred over steel due to their superior electrical conductivity. Furthermore, the design and construction of the machinery or equipment must comply with relevant electrical safety standards and regulations to ensure proper functionality and protection against electrical hazards.

- Q:What are the different joining methods for steel flat bars?

- There are several joining methods available for steel flat bars, depending on the specific application and desired outcome. Some commonly used joining methods for steel flat bars include welding, bolting, riveting, and adhesive bonding. 1. Welding: Welding is one of the most common and versatile joining methods for steel flat bars. It involves heating the surfaces of the bars to their melting point and then fusing them together using a filler material that acts as a bonding agent. This method creates a strong and permanent bond between the flat bars. 2. Bolting: Bolting involves using bolts and nuts to join steel flat bars together. It is a simple and effective method that allows for easy disassembly and reassembly if required. Bolting provides a strong and rigid connection between the bars, making it suitable for applications that may require frequent assembly and disassembly. 3. Riveting: Riveting is a mechanical joining method that involves using rivets to connect steel flat bars. It requires drilling holes in the bars and inserting a rivet, which is then deformed to secure the connection. Riveting provides a robust and durable joint, suitable for applications that require high strength and resistance to vibrations. 4. Adhesive bonding: Adhesive bonding involves using industrial adhesives to join steel flat bars. This method offers excellent flexibility, as it can bond different materials together and allows for uniform stress distribution. Adhesive bonding also provides good resistance to corrosion and can be used in applications where welding or other methods may be impractical or unsuitable. Each joining method has its advantages and limitations, and the choice of method depends on factors such as the application requirements, material properties, and cost considerations. It is crucial to select the appropriate joining method to ensure a secure and durable connection between steel flat bars.

- Q:Can steel flat bars be used for making shelving units?

- Yes, steel flat bars can definitely be used for making shelving units. Steel flat bars are strong and durable, making them an excellent choice for shelving units that need to support heavy items. They can be easily cut and welded to create the desired size and shape of the shelving unit. Steel flat bars also have a sleek and modern look, making them suitable for various styles of interiors. Additionally, steel is resistant to corrosion, which ensures that the shelving units will last for a long time without rusting or deteriorating. Overall, steel flat bars are a reliable and versatile material for constructing sturdy and functional shelving units.

- Q:Are steel flat bars used in the manufacturing of furniture?

- Yes, steel flat bars are commonly used in the manufacturing of furniture. They provide strength and stability, making them suitable for various applications such as table frames, chair legs, and shelving units.

- Q:Can steel flat bars be used for making window frames?

- Absolutely! Window frames can be made using steel flat bars. These bars are highly versatile and are frequently employed in construction because of their robustness and endurance. When utilized for crafting window frames, steel flat bars offer exceptional support and stability. They can be effortlessly tailored to accommodate various window dimensions and designs. Moreover, steel flat bars possess excellent resistance to corrosion, rendering them suitable for outdoor applications. All things considered, opting for steel flat bars to manufacture window frames is a pragmatic decision that guarantees enduring and dependable windows.

- Q:Can steel flat bars be welded or joined together?

- Steel flat bars can indeed be welded or joined together. The process of welding is widely employed to join metal components, including steel flat bars. During welding, the edges of the steel bars are melted and fused together using a welding filler material. This results in a robust and long-lasting bond between the flat bars. However, it is crucial to verify that the steel flat bars being welded possess the same or similar composition to avoid any complications with the quality of the weld. Moreover, employing appropriate welding techniques and equipment is essential to attain a weld of superior quality and guarantee the structural soundness of the joined steel flat bars.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords