Customized 5052 H36 Wide Aluminum Coil of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

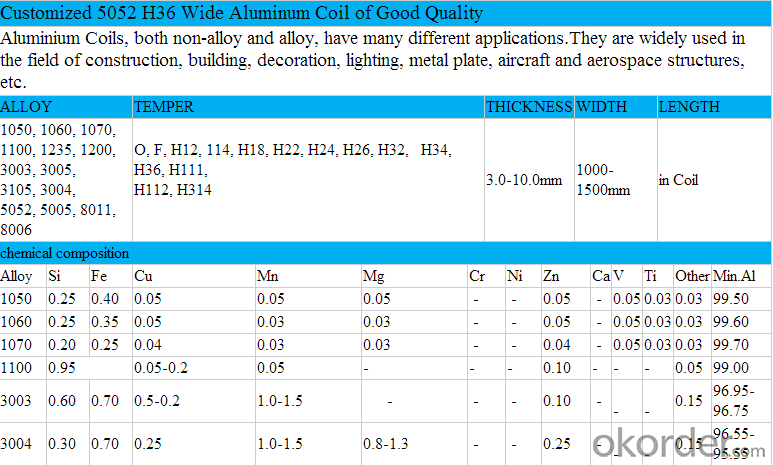

Customized 5052 H36 Wide Aluminum Coil of Good Quality

Aluminum coil is a kind of metal product. Rolled through by casting machine and processed by pull corner machine, aluminum coil is ready for the conduct of the shears. It is widely used in manufacturing aluminum thin sheet and aluminum foil. Aluminum coil is suitable for further machining with original standard quality. It is easy to controll and manufacture according to each customer's requirements.

5000 series aluminum alloys are more commonly used aluminum series, the main elements of magnesium, magnesium content between 3-5%. Also it can be called aluminum-magnesium alloy.

Aluminum Coil Specification:

l Packaging&Shipping

Packaging detail: Standard seaworthy exporting carton, wooden pallets, waterproof paper and plastic coverage or as customer's requirements.

Delivery detail: About 25 days from received original L/C or advance payment.

l Features

1. Name: Customized 5052 H36 Wide Aluminum Coil of Good Quality

2. Temper: O, F, HXX

3. Thickness: 3.0-10.0mm

4. Width: 1000-1500mm

5. Type: Coil/Roll

6. Surface Treatment: Mill finished

7. Application: Decoration, packaging, printing, covering

8. Standard size: Upon customer's demand

9. Quantity: 18tons(±10%)in one 20 feet container

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42800 employees and sales in 2005 of US Dollar 4.395 billion.

The Aluminum Product Department of CNBM manufactures and sells aluminum products including aluminum coils, aluminum foils, aluminum sheets, aluminum circles etc. With strong technical strength and strong ability to innovate, CNBM aluminum coils are being sold to many countries in around the world.

l CNBM World Wide

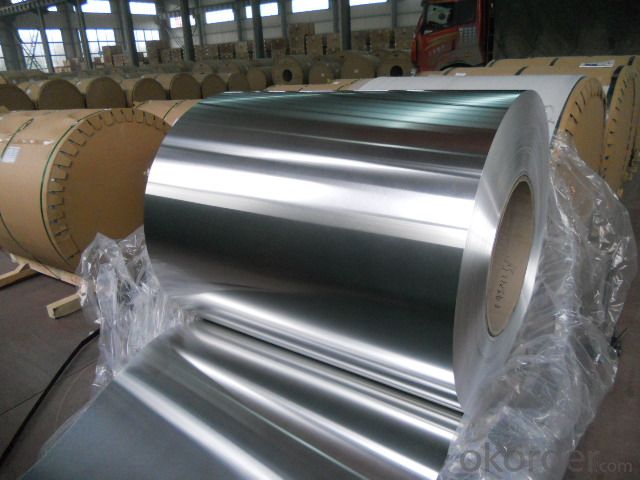

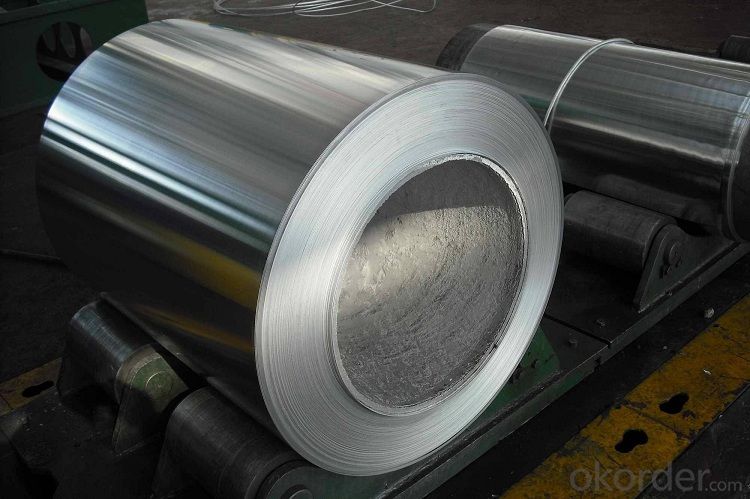

l Products images

l FAQ

Q: Do you provide free samples?

A: Yes, free aluminum coil samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

Fore more information about aluminum coil or other aluminum products, please contact service@okorder.com

- Q:I'm trying to cast aluminum using plaster and i was wondering if any one know how much the plaster has to be baked and how to tell if the plaster is dried fully and ways to do it. thx

- Plaster releases water at two points - in ordinary or accelerated drying it loses the water needed for setting and stops feeling cool and feels dry. If it is heated past 900F it loses chemically bound water and may fall apart. Aluminum melts at several hundred degrees higher than this and if the mold is intended to hold a mass of aluminum is is likely to destroy the mold. If the aluminum casting is fairly flat less of a problem. The common method for dealing with this is to add 50% silica flour (bad for lungs warning) to the dry plaster when making the mold. Then the mixed material mold can be used and preheated to take materials at least up to fused/molten glass, although the mold is commonly lost (not reusable) at these temps and just barely holds together.

- Q:I know aluminum has gone up in price. I know very little about gutter material. Durability, leaf guards, etc. I am on a limited income, and need the most and best for my few bucks. Thanks Lee

- Use Aluminum gutters with the leaf guard drip edge system. You can get them in a seamless design from a pro contractor (check Licenses ). You will not have to clean them. Plastic gutters ot leaf guards deteriorate (dry rot) and become brittle.

- Q:can you use the Brasso Aluminum cleaner on aluminum wheels? i have a set of mickey thompson classic II wheels and i want to polish them up. they have water spots that are almost impossible to clean. how can i shine them up to make them almost like chrome wheels? i heard brasso works great but then i heard it damages the wheels?

- hello ,it says aluminum cleaner !!!

- Q:What are the factors that affect the cost of aluminum coils?

- There are several factors that can affect the cost of aluminum coils. 1. Raw material costs: The cost of aluminum, which is the primary material used in manufacturing coils, can fluctuate based on global supply and demand as well as market conditions. Changes in the price of aluminum can have a direct impact on the cost of aluminum coils. 2. Manufacturing process: The production process involved in making aluminum coils can also impact their cost. Various techniques such as casting, rolling, and annealing are used, and each method has its own associated costs. The complexity and efficiency of the manufacturing process can influence the final price of the coils. 3. Size and specifications: The size, thickness, and specifications of the aluminum coils can affect their cost. Larger coils or coils with specific dimensions may require additional raw materials, processing time, or specialized equipment, which can contribute to higher costs. 4. Surface finish: The type of surface finish applied to the aluminum coils can also impact their cost. Coils with a higher-quality finish, such as brushed or coated surfaces, may be more expensive due to the additional processing and materials required. 5. Quantity and order volume: The volume of aluminum coils ordered can often impact the cost. Larger order quantities may lead to economies of scale, resulting in lower unit costs. Conversely, smaller orders or customized specifications may incur additional setup costs or higher per-unit prices. 6. Market competition: The level of competition in the aluminum coil industry can affect pricing. If there are numerous manufacturers offering similar products, prices may be more competitive as companies strive to attract customers. On the other hand, if there are limited suppliers or unique product offerings, prices may be higher due to reduced competition. 7. Transportation and logistics: The cost of transporting aluminum coils can also influence their overall price. Factors such as distance, mode of transportation, and fuel prices can impact shipping costs, which in turn can be passed on to customers. It is important to note that these factors are not exhaustive and can vary depending on the specific circumstances and market dynamics. Additionally, other external factors such as taxes, tariffs, and government regulations can also affect the cost of aluminum coils.

- Q:Are aluminum coils suitable for solar panel applications?

- Yes, aluminum coils are suitable for solar panel applications. Aluminum is a lightweight, durable, and corrosion-resistant material, making it an ideal choice for solar panels. It provides excellent heat dissipation, ensuring optimal performance and efficiency of the solar panels. Additionally, aluminum is readily available and cost-effective, making it a popular option in the solar industry.

- Q:I am writing a science-fiction story, and I am planning on making Aluminum this ultra-valuable element (Which adds irony - Aluminum is the third most abundant element on Earth!) Even if ol' atomic no. 13 is as common throughout the universe as it is on Earth, I can bring up 'multiverse' to get away with it. I think it'd still be nice to know.

- Interesting, the aluminum must flow? Aluminum is not as common as other elements. It is not readily produced in the cores of stars through the alpha-capture process (which produces things like carbon, oxygen, neon, magnesium, silicon, etc.). This means it is only produced via supernova explosions. The table in Wikipedia (see link below) will give you an idea of the relative abundance to other elements. (Notice that magnesium and silicon, which are before and after aluminum, are nearly 100 times more abundant). As a fellow, Sci-Fi enthusiast, I'd remind you to make you're story believable. If you decide that your universe won't have supernovae, remember that would mean there would be no iron, gold, uranium, etc. My answer has been long enough, but I'm sure you have an idea why aluminum is so abundant on the Earth's crust so I'll stop here.

- Q:What are the different forming processes for aluminum coils?

- There are several different forming processes that are commonly used for aluminum coils. These processes include: 1. Hot rolling: This is the most common method used to form aluminum coils. It involves heating the aluminum to a high temperature and then rolling it between two large rolls to reduce its thickness. This process allows for precise control of the thickness and shape of the coil. 2. Cold rolling: This process is similar to hot rolling, but the aluminum is cooled to room temperature before it is rolled. Cold rolling is often used to produce coils with a smoother surface finish and tighter tolerances. 3. Continuous casting: In this process, molten aluminum is poured into a continuous casting machine, which produces a continuous strip of aluminum. The strip is then cooled and coiled to form aluminum coils. Continuous casting is often used for large-scale production of aluminum coils. 4. Extrusion: This process involves pushing aluminum through a die to create a specific shape or profile. The extruded aluminum is then cooled and coiled to form aluminum coils. Extrusion is commonly used to produce coils with complex shapes or profiles. 5. Slitting: Slitting is a process used to cut aluminum coils into narrower strips. It involves passing the coil through a set of rotating blades that cut the coil into multiple smaller strips. Slitting is often used to produce coils with specific widths or for further processing. These are just a few of the different forming processes that can be used to produce aluminum coils. The choice of process depends on factors such as the desired shape, thickness, and surface finish of the coil, as well as the production volume and cost considerations.

- Q:Can aluminum coils be used in the production of automotive body panels?

- Automotive body panels can indeed utilize aluminum coils. This material, being lightweight and extremely malleable, is an excellent option for automotive purposes. It strikes a fine equilibrium between strength and weight, thereby enhancing fuel efficiency and overall vehicle performance. Furthermore, aluminum boasts exceptional resistance to corrosion, a vital characteristic for body panels enduring harsh environmental conditions. The popularity of incorporating aluminum coils in the production of automotive body panels has been steadily rising as automakers endeavor to lessen vehicle weight and enhance sustainability.

- Q:I want to paint my cars rims and grill metallic pink. But supposedly paint doesn't stick well to aluminum. What can I do to make it stick better and not chip?

- make sure the aluminum is ruffed up with at least 800 grit sand paper after that clean well and make sure is is dry after you clean after that use a product called adhesion promoter it will help the paint stick to the wheel hope this helps

- Q:wikipedia says welding aluminum by means of stick welding is possible but i have always been told TIG is the only way to weld aluminum. what do i need in order to stick weld aluminum? BTW i have a Lincoln Electric AC 225 Stick Welder

- Stick Welding Aluminum

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Customized 5052 H36 Wide Aluminum Coil of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords