Mens Stainless Steel Cross

Mens Stainless Steel Cross Related Searches

Men's Stainless Steel Cross Stainless Steel Cross Mens Stainless Steel Chain Stainless Steel Mens Chain Stainless Steel Crosses Stainless Steel Chain Mens Men's Stainless Steel Chain Mens Stainless Steel Chains Men Stainless Steel Chains Stainless Steel Chain Men Stainless Steel Cross Chain Stainless Steel Male Chastity Stainless Steel Crucifix Stainless Steel Post Stainless Steel Jewlery Stainless Steel Strap Stainless Steel Jewellery Metal Stainless Steel Stainless Steel Collar Stainless Steel Stainless Stainless Steel Jewelery Stainless Steel Neckless Stainless Steel Signs Material Stainless Steel Stainless Steel Belt Stainless Steel Hardware Stainless Steel Counter Chrome Stainless Steel Stainless Steel Engraving Stainless Steel SignageMens Stainless Steel Cross Supplier & Manufacturer from China

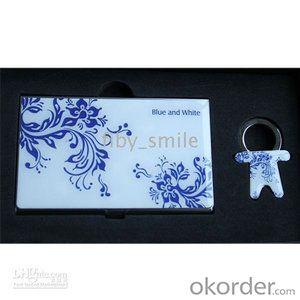

Mens Stainless Steel Cross is a collection of high-quality, durable, and fashionable accessories designed for men. These crosses are crafted from premium stainless steel, ensuring that they are resistant to rust, corrosion, and tarnishing. The products in this collection come in various sizes, styles, and finishes, catering to different preferences and tastes. The intricate designs and attention to detail make these crosses a popular choice for those seeking a stylish and meaningful accessory.The Mens Stainless Steel Cross is suitable for various occasions, from casual outings to formal events. It can be worn as a pendant on a necklace or bracelet, or even as a lapel pin or keychain. These crosses make excellent gifts for friends, family members, or loved ones, especially those who appreciate religious or spiritual symbols. They can also be used as a daily reminder of one's faith and beliefs, providing a sense of comfort and reassurance.

Okorder.com is a leading wholesale supplier of Mens Stainless Steel Cross, offering a vast inventory of these products at competitive prices. With a wide range of designs and styles to choose from, customers can easily find the perfect cross to suit their needs and preferences. The company's commitment to quality and customer satisfaction ensures that each cross is crafted with care and attention to detail, making them a popular choice among retailers and consumers alike.

Hot Products