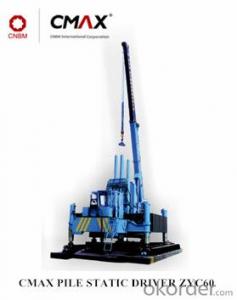

ZYC60 Used Pile Driver Hydraulic Static Pile Driver for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC60 Used Pile Driver Hydraulic Static Pile Driver for Sale

| Lower Energy Consumption: |

>>We use variable hydraulic systems with low loss and constant power in this series of products, so that energy consumption decreases by 30% and working efficiency increase by 60%. |

| High Efficiency: |

>>To ensure the high working efficiency of the whole machine, we use hydraulic systems with big power and great flow, the pile driving mechanism with multi-speed control and being quick in getting ready for operation. |

High Reliability: |

>>To ensure the high reliability of our products which engineering machines should possess, we improve the design and use very reliable materials or components which we select carefully in the process of purchasing. |

|

Convenience in dismantling, transportation and maintenance: |

>>Since we have constantly improved our design of pile drivers for more than 10 years, every part of the machine is easy to be taken apart, which provides convenience in transportation and maintenance. |

|

Multi-function: |

>>Our products are multi-function static hydraulic pile drivers with embracing pile driving, top-pressing pile driving or both at the same time because they are well combined with each other. |

|

Systemization and Maximization: |

>>Our company has developed 14 models of pile drivers with the capacity of 60 tons to 1200 tons and each model is classified into 4 kinds according to its function with the maximum tonnage of 1200. |

|

Flexibility in Designing: |

>>To keep up with the development in the engineering machinery of the world, we will integrate all useful high technologies from machine-building, electricity, hydromechanics and electronics into our products and meet different individual needs of our customers. |

|

| Two Patents: |

>>The design of inverted cylinder as a supporting leg which avoids the radial force on the piston extends the life-time Of the cylinder. |

| Parameter/Model | ZYC60 | |

|---|---|---|

| Rate piling pressure(KN) | 600 | |

| Piling speed(m/min) | Fast | 4.0 |

| Low | 1.1 | |

| Piling stroke(m) | 1.4 | |

| Pace(m) | Longitudinal | 1.4 |

| Horizontal | 0.4 | |

| Angle range(°) | 15 | |

| Rise stroke(m) | 0.6 | |

| Square pile(mm) | Max | 300 |

| Circle pile(mm) | Max | ... |

| Side piling(mm) | 400 | |

| Corner piling space(mm) | 800 | |

| Lifting weight(t) | 5.0 | |

| Pile hanging length(m) | 7 | |

| Power(KW) | Piling | 15 |

| Lifting | 7.5 | |

| Main dimension(m) | Work length | 5.44 |

| Work width | 3.8 | |

| Transpot height | 2.6 | |

| Total weight(t) | 60 | |

Advantages

1 sincere

CNBM International is a state company, now is one of the largest state-owned group cooperation in China! All the outdoor heaters produced by CNBM are compliant with the national level quality.

2 professional

Our engineers will at your services 24hours to answer your questions. Our goal is to provide the best professional services.

3 quality

CNBM International’s outdoor heater have strict quality control, only the best quality products can pass the test.

4speed

We have professional sales team to guarantee your reply within 12hours to save your precious time.

5 After sales

If the tower crane has any problems, we will solve your problems in first time.

Others

1.Reply your inquiry in 24 working hours.

2.Experienced staffs answer all your questions in professional and fluent English.

3.Customized design is available. OEM is welcome.

4.Exclusive and unique solution can be provided to our customer by well-trained and professional engineers and staffs.

5.Special discount and protection of sales area provided to your distributor.

6.Do the best reliable heavy-duty single drum vibratory road roller in China.

7.Warranty period is 1-year or 1500 working hours against Bill of Lading.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

e. To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

f. On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

g. Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

- Q: But in a few days, wait for the water to ease up, and plug it directly with earth rockIs there no way directly to seal the breach?

- The width of 340 meters, so excited water, so a wide breach, the water is so deep, the boat stopped, so how long pile up? Where is the man standing? People have no place to stand. How can the pile driver be put into the wooden pile? Under such circumstances, even if there is a pile driver, what's the use? This is the changkai dike breach after there are no reasons for piling piling machine.Answer to your supplementary question:Closure of crevasse is a system engineering, it should include: pile, piling machine, operating platform, platform connection between the anchor pile, etc.. Not only one or two of them can be done.The following is the Liyang Ding Ding Mini piling equipment factory produced dragon dragon brand dam information, hoping to help answer your questions, if you do not see clearly, you can click on the map to see the original picture.First, dragon Ding card dam mapSorry, I'm only level one now. I can't upload pictures. If necessary, go to the website of the new tripod piling equipment factory in LiyangTwo, the Dragon Dingpai dam burst when the working drawing of pluggingThree, dragon card blocking effect after the burst dam closure graphWhen all of the pile are good, can seal the 90% water, finally burst all filled with debris, if there is enough manpower, also can be in front of the pile at the same time, immediately behind the embankment filling. Crevasse sealing is completed, will pull out all the repeated use of pile.

- Q: How much can a pile driver make in a year?

- Hello Can contact Huilong spiral drill, rotary drilling is burning diesel, the average is 40 or so, to see what much of the diesel engine, what brand of Oh ~ what needs, you can consult a wylong machinery in Hunan!

- Q: How much is the hydraulic pile driver?

- Between 16-40, 000. Different manufacturers. Different tonnage difference big ah, soft land dozen20 tons will be enoughI hope my answer is useful to you, if satisfied, please take ~!

- Q: Several common pile foundations and pile driving techniques

- Bored pile foundation construction - long spiral drilling bored pile construction, the main processes are: site preparation, the laying of protective cylinders, preparation of mud, drilling, cleaning, reinforcement cage, into the hole and pouring underwater concrete. The key is drilling, the main methods are: rotating method, impact method and punching method. The rotary drilling can be divided into positive revolving drilling, reverse circulation rotary drilling, long spiral drilling machine and so on. Bored pile foundation construction - reverse and reverse rotating drilling, positive rotation drilling: mud from the mud pump at high pressure from the mud tank into the bore of the drill pipe, the drill hole through the mouth of the injection.

- Q: Why do some people need to dig the foundation and pile it up to dig a hole?

- First of all, depends on the type of your pile, prefabricated or bored pile.If it is a bored pile, then it is obvious to dig first.If it is a prefabricated pile, then pile it directly, then dig it.

- Q: How much money piling machine, which is good

- Depends on how big you buy, Shandong force strong pile driving function to play within 20 meters deep, within a meter of aperture, online direct search can find him

- Q: What's the use of a pile driver?

- See what you have needs for foundation piling piling machine, as well as for piling machine polishing V pile, as well as for highway guardrail guardrail installation pile piling machine, and a spiral piling machine. The foundation of the piling machine are large, the appearance looks a bit like a machine modification, it is actually the crawler chassis, and digging machine, guardrail piling machine is much also, now what are the loading type, vehicle type. There are many kinds of piling machines, such as the machines in Chengdu, what type 260, the loading type, the all-in-one, and so on.

- Q: Buying a pile driver doesn't know how to make a profit Has anyone done that yet?

- (personal advice not to buy Nantong machines, Nantong machines, good and bad, before the site was used in Nantong machine, although the price is cheap, but there are many problems, and now the site basically does not need)Hit the general pile, pile driver 8 tons on it, of course, it is best to choose a strong load capacity, or once the load, the machine easily damaged. To goods than three, can not blindly pursue cheap, otherwise it is easier to lose than gain. To pursue a low in the high quality, cost-effective high is really good.

- Q: How much are the pile and Larson piles of a pile driver?

- Would you like to ask the price of the material or the price of the construction?AskMaterial priceChasing the answerI mainly do Larson steel sheet pile products. Domestic 5000 or so, Japan imports 6450.

- Q: What is the maximum CPU of a pile driver? What about the performance of graphics will be piling machine CPU?

- The official use of Bulldozer as the core code shows the unmatched performance of the CPU series.The bulldozer is the United States AMD company to re design of the CPU architecture, officially launched in October 2011, have a fever for high-end user, with DDR3-1866MHz native memory support, XOP instruction set, the modular design and a number of new features, fully replace the phenom processor of II series.

Send your message to us

ZYC60 Used Pile Driver Hydraulic Static Pile Driver for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords