Wood Plastic Composite Wall Panel WPC Cladding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

FAQ

3> Why choose WPC decking?

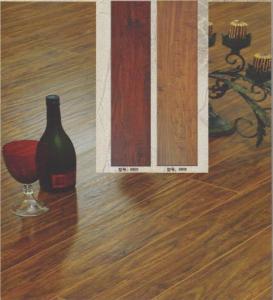

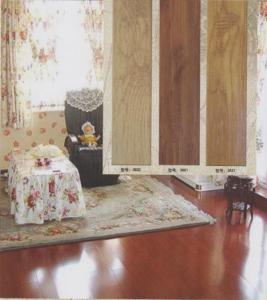

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

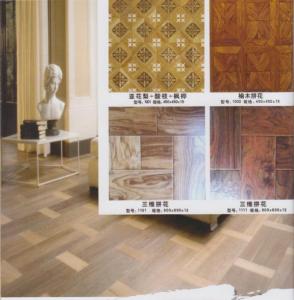

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

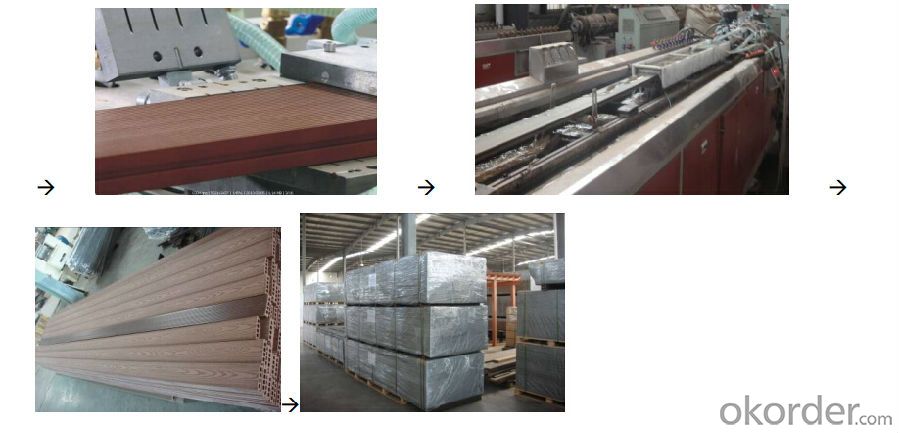

6> How’s WPC made?

7> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

C. Surface treatment

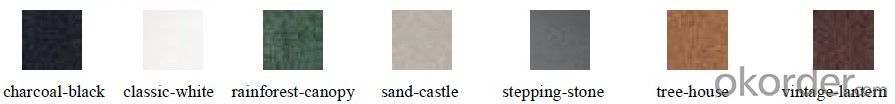

D. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

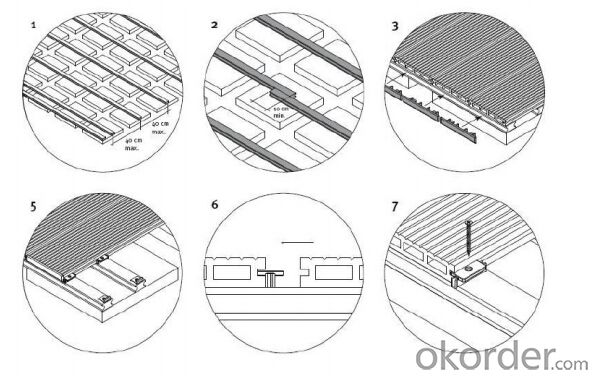

E. How to install

Company Information

8> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

Our unique advantages:

* Preferential payment terms

* Good and reasonable price

* Quality guarantee -- CNBM won't let a single small deal ruin our reputation and brand, so quality is

our lifetime.

* Professional team for CRM order processing & QA & logistics

*Global logistic database, originated from Dubai

- Q: What is the size of the plastic floor?

- General Coil: Thick (1.6mm-3.0mm) * Width 1.83m * Length 15m

- Q: I have been cleaning my laminate flooring with some cleaner just for laminate flooring and my floor keeps looking duller and duller with each cleaning. It is a new floor and I want it to look great not dull and old looking. Any suggestions?

- Just a little Vinegar and Water I recently had a Shaw laminate floor installed in my kitchen. I called their customer service representative to ask the best way to clean their flooring. She told me to use 1/4 cup of vinegar and put it in a 30 to 32 ounce empty spray bottle filled with plain water. I purchased a terry mop cover that has elastic all around it from Home Depot, which I dampen with water and place on a Swiffer dry mop head. I then spray the floor (a small area at a time) with the vinegar/water solution and then wipe it up with the damp terry mop. It does a good job. There is no streaking, and you are using very little water on the floor. One company has come out with wet cloths to attach to Swiffer mops that contain vinegar and water, which I also plan to purchase and try. Make Cleaner at Home To make laminate floor cleaner, mix 1/3 white vinegar, 1/3 rubbing alcohol, 1/3 water, and 3 drops dishwashing liquid for a quart total. For best results, wipe off quickly.

- Q: The floor is buckling up in one spot even though the floor is brand new. I believe the pieces may not be staggared enough to give it the strength to keep it from buckling up. I believe I can re-use alot of the pieces. I think I may have to pull up the floor and reinstall. any other suggestions?

- different than gluing the chips returned in place, the subsequent genuine looking answer is to deconstruct the floor to the chipped products and rearrange the tiles with the chips someplace no longer interior the middle, or replace them altogether. If counters have been positioned on top of the floor, this could be a lot tougher.

- Q: Do stages have sprung floors. I heard it is bad to dance on a floor that doesn't give any. So if the stage isn't sprung you could get injured. So do they have sprung floors? Thanks in advance!

- No they don't. But that is why we use our plié. So we don't get injured, but get the same spring.

- Q: HOW do you take a toliet up, and fix the floor before it falls in .

- Taking the toilet up is the easy part. There should be two bolts on the sides of the base that have to come loose. A lot of the time these are rusted or corroded so badly that you have to use a hacksaw to cut them off. You'll need to cut the rotten part of the floor out to the center of the floor joists that are past where the rot stops. In the space between the joists it's a good idea to install a piece of lumber the same size as the joists between them so that the end of the new piece of plywood is sitting on something. Position the new piece so that it will be half under the old plywood so that it will support both the old and new pieces. Basically you want a square frame to hold up the new piece of floor you'll be putting down. The biggest problem is usually that since the toilet sits so close to the wall that sometimes the water damage extends underneath the wall. If that's the case, then I'd suggest calling in someone with experience. If not, then cut a piece of 3/4 inch plywood to fit the hole that you cut out. If you're putting linoleum of something soft down for the floor, then use wood putty to fill the gap between the old and the new sub-floor otherwise you'll be able to see where the gap is because the flooring will eventually sink into the gap. If you're doing tile, you shouldn't have to worry about it.

- Q: I have old hardwood floors throughout most of my apartment. I have been using Murphy's Wood soap, and the floors feel clean to the touch, but there's always black on the bottom of our socks and the floor look murky, like there's a gray film over them. I have small kids so I want to try to avoid anything too harsh, but I'm getting sick of these floors. I wash them at least three times a week and they still look dirty. Any ideas?

- I wish I could see it but since I can't. Do you wear shoes in the house? If you have a lot of people traffic you may want to go to a no shoes rule. Get a good doormat. Mopping is sometimes not abrasive enough but if it feels clean maybe that is not the answer. Bleach the kids socks or soak them in Oxyclean. I love Murphy's oil soap it's good stuff. Start looking around for attractive rubber backed throw rugs. If the floors don't look good cover 'em up. Kohls and Marshalls are good places to look.

- Q: Accidentally sprinkle nail polish on the floor of the tiles, how to do?

- There are ways to use the best, there is no smell, Fan Erdun old turtle ransing some rogue nail polish oil, we all said, but what is the oil is not smell it? Answer the wind spirits you fine oil on the nail polish, after a while wiping a wiping a good ~ ~ there is a kind of cool taste ~~~~~~~~~~~~~

- Q: When laying solid wood flooring how much loss rate is normal?

- One: the normal loss is about 3% (error 1%), which is 2% -4%, the national standard is 5% -10% (actually the floor to protect the floor manufacturers to protect the loss), home area is small, as long as you carefully Point floor wear can be calculated, such as home floor is 40 square meters, loss of 2 square meters is enough. Second: the baseboard meters and floor area figures are the same (such as the floor is 42 square feet, the base line is 42 meters). Three: 1) If it is a small room so every door must have a bridge, but not necessarily copper (now basically no), the color of the bridge and the floor color to close, the color is too yellow bar. 2) If it is Siamese do not have a bridge, the continuity of the floor damage, the overall effect is not good. Four: the floor is very important to install, the master of the decision to use your home floor effect and life.

- Q: I want to buy a steam mop to clean my laminate floors, but am afraid that the moisture may hurt the laminate. Please advice, thank you

- Wood laminate floors are less expensive than hardwood floors and are much easier to install. Since wood laminate floors can be installed over virtually any surface, most homeowners install wood laminate floors themselves. For this reason, wood laminate floors are a great alternative to installing hardwood floors. Cleaning a wood laminate floor is just as easy as long as you have the right cleaning supplies.

- Q: recently decorated my room and paint must have dripped on the floor, ant tips on removing it? its laminate

- scrape off the paint then wet the area and gently rub wif a smooth sanding pad not sandpaper

Send your message to us

Wood Plastic Composite Wall Panel WPC Cladding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords