wpc wall cladding /wood plastic composite wpc decking/wpc cladding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical addatives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

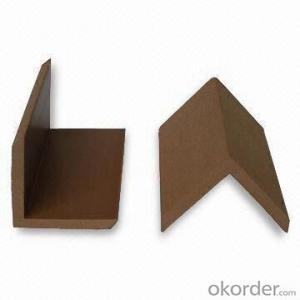

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q: How does the floor stand up?

- Demolished the pavement again, as long as the mouth is not bad on the line, a pair of each other on the line, very good fight

- Q: Nature, icon, peace of mind floor, these three kinds of solid wood and composite purchase price each? Thank you more

- These brands at that time I also looked at the last choice of peace of mind some people feel good just to see more in the ad above, but the price is not so people can feel satisfied. If it is to change the wood floor, then you can look at the peace of mind, my family is now using this brand of solid wood flooring, and now there are four years fast, did not appear what the problem of cracking, and peace of mind after-sales service Also feel comfortable, interested, then may wish to refer to the next.

- Q: What is the difference between the solid wood flooring and the flooring in the installation?

- Solid wood flooring installation in two ways: empty shop method, real shop method. Empty shop method of the higher cost, but the foot feeling comfortable, long life, and the ground is not demanding. The construction process of the empty shop method is to lay the dragon skeleton first, and leveling the ground, and then laying a layer of large core board, in the big board on the floor floor. Shaving method is the method of laying the floor directly on the ground. The construction process is simple, suitable for the ground condition is better, the duration of the project. Solid wood flooring use for a long time after the surface will be wear, can be re-polished, color, paint, the old as new. The installation of the composite floor is called suspension installation, that is, the floor is suspended above the ground. Pavement when the first leveling the ground, and then lay a layer of polyethylene foam pad, foam pad to play the role of tide and leveling, but also increase foot feeling. Floor shop on the foam pad, from the first three rows, should be dry and then continue to pave the skin, curing time of about 3 hours. The daily handling of the composite floor is very simple, just wipe with a semi-wet semi-dry mop. Composite floor of the surface is very wear-resistant, good quality composite floor life can be up to ten years.

- Q: How to identify the quality of composite flooring?

- First, the color of paper, look at the surface of the color is naturally not really second, wear-resistant layer, to see the surface of the wear resistance, the state to achieve more than 4500 turn can be used in the family, the general manufacturers have reached more than 6000 rpm Third, the environmental protection level traces of Cao Ke 丨 long check Hsue magic, is the release of formaldehyde

- Q: Composite floor fire effect is good?

- Fire effects mainly look at the surface technology and substrate. Excavation of composite flooring is mainly biased in favor of fire protection. Strengthen the composite floor that is fire retardant floor. The fiberboard, particleboard, plywood, etc. as the substrate, with paint or impregnated paper for the finishes, through the flame retardant treatment, to achieve a certain flame retardant grade, with flame retardant wood composite flooring.

- Q: That is clean and easy

- dedicated. Or non-exclusive cleaning agents,

- Q: Or solid wood (also see what the wood, such as two-winged beans, etc.), but the composite price is better, not easy to change, good care.

- Look at the extent of the original damage to the floor, if there is no big problem directly shop is ah!

- Q: Such as title

- With a rag dipped in hot water can be removed more rub, rub clean and then wash the towel.

- Q: Want to wax? How to play better

- No need, only solid wood flooring needs waxing

- Q: Sales master laminate flooring master said that do not have to do to promote the production of the floor, the floor of the master said, "Strengthen the composite floor to do curing to maintain its long." No search for the answer. Please have experienced master answer. Question added: Will the use of conservation to strengthen the composite floor. More

- Should be done warranty, and good

Send your message to us

wpc wall cladding /wood plastic composite wpc decking/wpc cladding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords