WKM Expanding Gate Valve with API 6A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of WKM Expanding Gate Valve Description

1) Metal-to-metal sealing (gate-to-seat and seat-to-body).

2) Expanding gate design creates a positive mechanical seal across the seats, with or without line pressure.

3) Full-bore, through-conduit gate-to-seat seal maximizes valve life by virtually eliminating turbulence and pressure drop.

4) Gate skirts reduce loss of body lubricants.

5) Low running stress enhances life of the gate-to-seat interface.

6) Upper/lower roller thrust bearings are isolated from well fluid, minimizing torque.

7) Stem packing can be re-energized with valve under pressure.

8) Non-rising stem permits valve installation in closer quarters.

9) Seats, gates, stem, and other working parts are field replaceable.

2. Main Features of WKM Expanding Gate Valve

1) Advanced test for quality

2) MTC provided

3) Good price and service

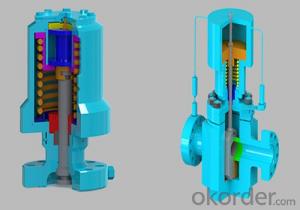

3. WKM Expanding Gate Valve Images

4. WKM Expanding Gate Valve Specification

Working pressure: 2000-5000PSI

Nominal size: 2-1/16"~7-1/16" (46mm~180mm)

Working temperature: - 46℃~121℃(LU)

Material class: AA、BB、CC、DD、EE、FF

Specification level: PSL1-3

Performance Requirement: PR1

Working medium: oil, gas, mud, gas contain in H2S、CO2

5. FAQ of WKM Expanding Gate Valve

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing Oilfield products in China, mainly offering various of oilfild products consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: I was considering making a ball valve PVC air rifle or something of the sort using a PVC air canister and a hand pump, but I wanted to know about it, last year I made one that was air tight but air leaked out of the top of the pump which really annoyed me, I looked further onto the it and found out that there was a Bike Tyre valve, What does it do? Does it let air flow in but stop it from coming out? and where would I find some good designs as well as the items needed to make it? And don't bother answering 'Buy an air soft gun' because Australia does not retail those.

- hi there in canada , at any big truck tire repair place they have tire valves that are like bunker fittings, that is to say a valve that has a threaded bottom end with nuts and rubber washers, you would drill the appropriate size hole in the pipe and put the valve through and tighten the nuts up against the washers making an air tight seal, that should work for you if they have them in au, good luck

- Q: When I flush the toilet it flushes just fine, but it doesn't fill again. You have to close the wall valve and then open it up again to fill the tank. Is this a problem with the valve or the internals of the tank? Thanks

- Check your fill valve (inside the tank) first. If it appears to be working properly, turn the water off outside the house, drain the tank, take the filler tube ( from the valve to the bottom of the tank on the outside) loose at the valve. Remove the valve and inspect for obstructions, such as calcium and or lime deposits. You may need to replace the valve as they will occasionally wash out over time. Reverse this process to put everything back together, and be sure to wrap the male threads on the supply line (pipe sticking out of the wall) with teflon tape.

- Q: Hey guys. I need help. Sorry this might not go here... but i couldnt find a 'good' category to put it in. This is for an engineering project for college.Im looking for shielded core solenoid valves that can with stand 95-98% sulfuric acid. With this in mind not very many materials are usable, right now we are looking for HDPE (High-density polyethylene).The size of the valves and cost is unimportant. Main thing is finding someone who sells HDPE solenoid valves.For more clarification on what we are looking for, below shows a shielded core solenoid valve from ASCO. The more acidic resistant material they offer however is a FKM. Which can only withstand ~60% sulfuric acid solutions.

- In practice, engineers do not use solenoid valves directly on chemical or process lines. They are bound to leak and cause danger particularly in your case of 98% sulphuric acid. Use a mechanical valve actuated by a motor (since cost is no issue to you) If an air supply is available, then you can use pneumatic diaphragm valve operated by a solenoid valve. Motorised valve has slower fixed open close time VS faster adjustable open close time for air operated valves.

- Q: I was just informed that my 4 year old daughter has been diagnosed with mild mitral valve regurgitation. I have been researching, but only find the information to apply to adults, not children.What general course is taken when dealing with children with this condition and what should I expect? Her pediatrician was treating her symtoms as asthma with breathing treatments, but, I was not comfortable and took her to my family physician, who sent her for the echo, which discovered this.I'm more or less just looking at our options...

- I am not completely familiar with this specific heart problem but my son was born with a CHD (congenital heart disease) called Tetralogy Of Fallot and has had 2 open-heart surgeries. He is only 2 years old but is and has been doing fantastic. I do know a few other parents with children with mitral valve regurgitation and they have had to have mitral valve replacements. When and or if this needs to be done depends on how severe the regurgitation is. You can go a LONG time with regurgitation of any valve. My son actually currently doesn't have ANY Pulmonary valve what so ever right now and hasn't sence his last surgery when he was 9 months. We are not looking for him to have a Pulmonary valve placement until he is about 5-7, so that will be 4-6 years with no Valve at all at 100% complete regurgitation!!!!! Hope fully your daughters isn't too bad and you can wait a few years for her to have a new valve. Children are more likely to reject valves and the sooner it is put in the sooner she will need a new mitral valve replacement. Pretty much anybody that gets a valve replacement will have to keep getting them every 10-20 years of their life depending on what kind of valve you choose, when it is placed and how good they do. Good luck to you and your daughter - heart kids are the strongest!!!!

- Q: My mom just went to DR and will have open heart next Thursday for removal of anyerisum. She was told she has 2 heart valves instead of four. What does this mean? Is it normal?

- Your mom probably has a Bicuspid aortic valve, that she was born with.. it means that the valve between her heart and the aorta has two valve leaflets instead of the usual three valve leaflets (not four) in normal people. Bicuspid aortic valve is caused by fusion of two of the three leaflets. It's a fairly common congenital condition, and is associated with a risk of aortic aneurysm (a weakening of the wall of the blood vessel which then causes ballooning of the vessel wall)...usually of the ascending aorta. All the best for her safe recovery.

- Q: do I need a new water heater or can this ne be fixed?

- It can be fised, you just need a new seal. Measure the width of your pipe and go get a little package of them. They probably cost $2.99. Turn your water off at the street, then drain your water heater to keep it from flooding and possible problems. unscrew the joint replace the washer and put it back together. There is a book you can get at book stores that's called Hoe To Fix Damn Near Everything. It is a must have and has saved me thousands of dollars over the years. Good Luck, Jackie b

- Q: I just fixed a clog in my bathroom sink by taking off the p-trap. I had turned off the water valve beforehand, and when I was done I turned it back on. After this, all that came out of the faucet was a trickle. Turning the valve in the off position does not stop the trickle. When I first turned the valve off before taking off the pipe, the valve was not turned all the way left or right. It was in the middle, but the water flowed fine. When I turned the valve all the way to the right, the water shut off at the faucet. My apartment is pretty old. Is this valve most likely broken?

- Being old plumbing, when you turned off the valve (which you did not need to do to work on the drain) debris probably broke loose in the water line. Turn the valve to the off position again. Disconnect the supply tube above the valve. Hold a rag over the top of the valve and turn it on and off a few times. this should tell you if there is a clog and may clear the debris out. Good luck.

- Q: My car has been sputtering and hesitating when I hit the gas. My friend's boyfriend says it is a bad erg valve does that sound right?

- An EGR valve being open will cause mostly idle problems and light throttle/initial take-off problems...mostly when you have a high manifold vacuum is when you end up with problems because of a sticking EGR valve. Just remove the valve and clean it by soaking it in something like B-12 Chemtool. I can garuntee you that valve is probably disgustingly full of carbon depending on the year.

- Q: my mid eighties GM full size car with a 305 just started to have a problem...it runs fine at idle.....runs rough/sluggish at speed......when I take my foot off the gas there is a fast rattle in the engine.........and sometimes the engine likes to idle fast.....I replaced the catalytic converter last year ...........so now I am thinking of changing the egr valve....there is no service engine soon light on and this car is a mid eighties so no obd 2 system on this car......any other ideas? thanks

- EGR valve got sooty,and rusty and dirty and then they dont work right. They either dont open or they get stuck open and cause the car to run lousey. If the valve has been i the car since the 80's it is probably about time to either clean it or change it. do you have haynes or chilton manual for the car? they explain alot.

- Q: Would a 96 saturn egr valve work on a 96 camaro

- You are wasting your thinking powers. Most EGR valves are easy to remove, and EASIER to just clean out with solvent. This will usually restore proper functioning. The reason they clog up is from a dirty IDLE AIR CONTROL VALVE, which causes fuel mixture to be too rich. THe excess carbon made then clogs up the EGR valve. CLEAN everything out, then install a set of Bosch Fusion, or DENSO Twin TIp spark plugs. These simply perform better, give more power, reduce carbon and exhaust emissions. and improve overall performance of EVERY engine controller! Throw the AC plugs in the trash where they belong!

Send your message to us

WKM Expanding Gate Valve with API 6A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords