Weled trench reinforcing rebar mesh for best quanlity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material | Low carbon steel, Ribbed steel, Deformed steel bar |

Type | Welded Mesh |

Standard | AISI, ASTM, BS DIN, GB, JIS |

Usage | Construction Reinforcement |

Hole Shape | Square |

Weave Style | Reinforcing mesh, Welded |

Product Code | Std Unit | Longitudinal Wires | Cross Wires | Mass(kg) | Dimensions(m) |

SL52 | sheet | 10×4.77@200+4×4@100 | 30×4.77@200 | 21 | 6×2.4 |

SL62 | sheet | 10×6@200+4×4.77@100 | 30×6@200 | 33 | 6×2.4 |

SL72 | sheet | 10×6.75@200+4×4@100 | 30×6.75@200 | 41 | 6×2.4 |

SL81 | sheet | 25×7.6@100 | 60×7.6@200 | 105 | 6×2.4 |

SL82 | sheet | 10×7.6@200+4×5.37@100 | 30×7.6@200 | 52 | 6×2.4 |

SL92 | sheet | 10×8.6@200+4×6@100 | 30×8.6@200 | 66 | 6×2.4 |

SL102 | sheet | 10×9.5@200+4×6.75@100 | 30×9.5@200 | 80 | 6×2.4 |

×Diameter (mm) × Spacing (mm) | |||||

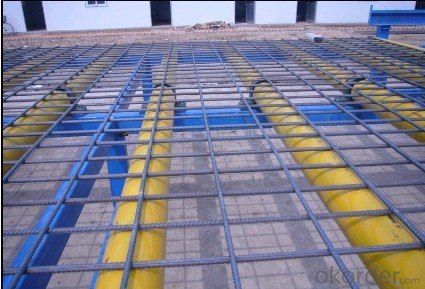

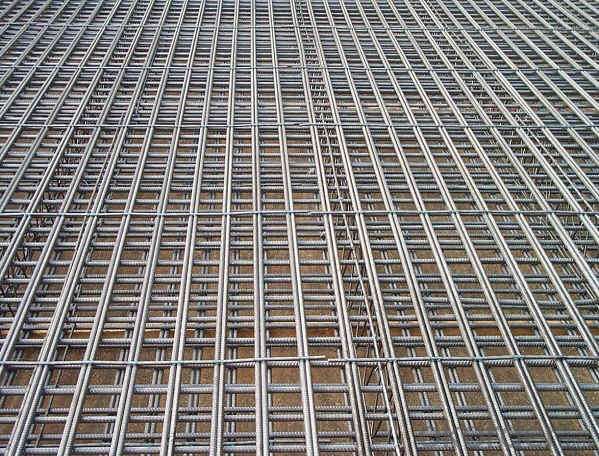

Product Display

Reinforcing wire mesh is a welded wire fabric, prefabricated steel reinforcement material.

It's made of Deformed Steel Bars or Steel Rod.

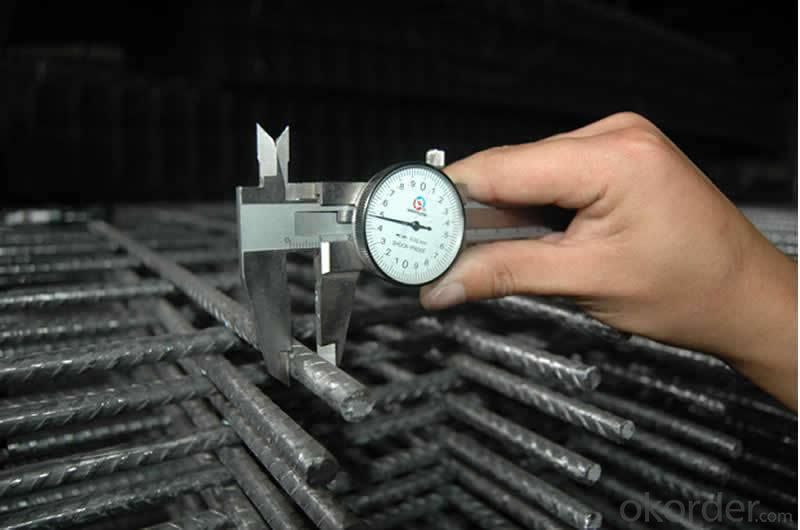

Wire diameter | 3mm-14mm |

Mesh size | 5*125px,10*250px,10*500px, 20*500px,10*750px,30*750px |

space | 50*50-200*200mm |

The fabric is used to provide tensile strength and crack control to structural concrete elements.

Welded mesh reinforcing is a convenient and cost effective alternative to conventional bar reinforcement for the following reasons:

1. The mesh is generally specified and manufactured according to standard references making for easy site identification, quality control and management.

2.The mesh is manufactured in sheets or rolls resulting in a quick and simple site installation process.

Application

1.Welded reinforcement steel wire mesh is widely used in construction filed,like housing floor, roof wall, terrace, concrete pavement.

2.Welded reinforcement steel wire mesh is also used in deck paving, airport runway, tunnel lining, concrete pipes, piles of industry and civilian.

3.Welded Wire Mesh can be used in wall,road for reinforcement.

- Q: Can steel wire mesh be used as a support structure for plants?

- Yes, steel wire mesh can be used as a support structure for plants. It provides a sturdy and durable framework for climbing plants or those that need support to grow upright. The mesh allows the plants to climb or wrap around it, ensuring proper growth and preventing them from falling over. Additionally, the open design of the mesh allows for air circulation and easy access for pruning or harvesting.

- Q: How is steel wire mesh used in the textile manufacturing industry?

- The textile manufacturing industry extensively employs steel wire mesh for a multitude of purposes. Among them, screens and sieves constitute a common application. These screens and sieves serve to segregate and categorize textile materials based on their size or to eliminate impurities. The robust and enduring nature of steel wire mesh enables it to endure the immense pressure and friction involved in this procedure. Furthermore, steel wire mesh finds utility in the fabrication of conveyor belts within textile manufacturing plants. These conveyor belts are responsible for the transportation of materials throughout the production line. The dependable and sturdy surface provided by steel wire mesh can effectively handle the weight and movement of the textiles being conveyed. Steel wire mesh also holds significant importance in the textile industry for the creation of drying racks. After undergoing processes such as dyeing or washing, textiles necessitate adequate drying prior to further treatment. Steel wire mesh racks are utilized to hang and stretch these textiles, facilitating uniform and expeditious drying. Moreover, steel wire mesh is incorporated in the construction of frames for textile printing screens. These screens are indispensable for the application of patterns and designs onto fabrics. The steel wire mesh frame imparts stability and support, ensuring precise printing outcomes. In summary, steel wire mesh assumes a pivotal role in the textile manufacturing industry by offering strength, durability, and versatility in various applications, including screens, sieves, conveyor belts, drying racks, and printing screens. Its utilization enhances efficiency, elevates product quality, and contributes to the overall prosperity of textile production processes.

- Q: Can steel wire mesh be used for construction purposes?

- Yes, steel wire mesh can definitely be used for construction purposes. It is a versatile material that offers numerous benefits in construction projects. Steel wire mesh is commonly used for reinforcing concrete structures such as slabs, columns, and beams. It provides additional strength and stability to the concrete, making it more resistant to cracks and structural failures. Furthermore, steel wire mesh can be used as a fencing material for construction sites, providing security and preventing unauthorized access. It is also commonly used for creating barriers and enclosures in construction projects, such as retaining walls, partitions, and cages. Another significant application of steel wire mesh in construction is in the form of gabions. Gabions are wire mesh containers filled with stones or other materials, used for constructing retaining walls, erosion control structures, and noise barriers. Steel wire mesh provides the necessary strength and durability to withstand the forces exerted by these structures. Additionally, steel wire mesh can be utilized in architectural applications, such as facades and decorative elements. Its malleability allows for creative designs and patterns, enhancing the aesthetic appeal of the construction. Overall, steel wire mesh is a reliable and versatile material that can be effectively used in various construction purposes, contributing to the structural integrity, security, and visual appeal of the project.

- Q: How is steel wire mesh used in reinforcement of food and beverage processing plants?

- Due to its strength, durability, and hygienic properties, steel wire mesh is commonly utilized in food and beverage processing plants to reinforce concrete structures. This reinforcement is essential in withstanding the heavy loads and vibrations often encountered in these industrial environments. Within the concrete flooring, steel wire mesh is frequently installed to provide additional support and prevent cracking caused by the pressure exerted by heavy machinery and equipment. By maintaining the structural integrity of the facility, this reinforcement promotes a secure working environment for employees. Moreover, steel wire mesh exhibits exceptional resistance to corrosion, enabling it to withstand exposure to chemicals, moisture, and high temperatures commonly found in food and beverage processing plants. This corrosion resistance contributes to the longevity of the reinforced structures, reducing the need for frequent repairs and maintenance. Additionally, the use of steel wire mesh in food and beverage processing plants enhances overall hygiene and cleanliness. The mesh's open design allows for proper ventilation and drainage, effectively preventing the accumulation of bacteria and contaminants. This is particularly important in environments where food safety is of utmost concern, as it minimizes the risk of contamination and ensures compliance with stringent regulatory standards. In summary, steel wire mesh plays a pivotal role in reinforcing food and beverage processing plants. Its strength, durability, and hygienic properties make it an ideal choice for reinforcing concrete structures, guaranteeing the safety, longevity, and cleanliness of these industrial facilities.

- Q: What are the different finishing options available for steel wire mesh?

- Some of the different finishing options available for steel wire mesh include galvanizing, powder coating, painting, and vinyl coating. Galvanizing provides a protective zinc coating to prevent rust and corrosion. Powder coating involves applying a dry powder to the mesh and then curing it to create a durable and attractive finish. Painting allows for customization with various colors and finishes. Vinyl coating adds a layer of plastic to the mesh, providing added protection and color options.

- Q: Can steel wire mesh be used for sunscreens or shading devices?

- Certainly, sunscreens or shading devices can indeed utilize steel wire mesh. This versatile material presents numerous advantages when employed in these applications. Primarily, it offers effective protection against sunlight by obstructing a substantial portion of the sun's rays, thereby reducing heat and glare. This renders it an ideal option for crafting shading devices suitable for outdoor spaces like patios, pergolas, or even window coverings. Moreover, steel wire mesh is renowned for its durability and strength. It can endure harsh weather conditions and is resistant to corrosion, making it suitable for long-term use in outdoor settings. Furthermore, steel wire mesh allows for ample airflow and ventilation while simultaneously providing sufficient shade, which is crucial for maintaining a comfortable and pleasant environment. Additionally, steel wire mesh can be tailored to meet specific design requirements. It comes in various sizes, patterns, and finishes, offering flexibility in creating distinctive and visually appealing shading devices. Whether it be a simple mesh screen or a more intricate design, steel wire mesh can be easily customized to complement different architectural styles and personal preferences. To conclude, steel wire mesh proves to be an excellent choice for sunscreens or shading devices due to its capacity to effectively block sunlight, its durability, and its customizable nature. It provides a practical and aesthetically pleasing solution for generating shade in outdoor areas while facilitating airflow and ventilation.

- Q: Can steel wire mesh withstand high temperatures?

- Yes, steel wire mesh can generally withstand high temperatures. The specific temperature limit, however, depends on the type of steel used and the manufacturing process. Some steel wire mesh products are specifically designed for high-temperature applications and can withstand temperatures ranging from 500 to 1000 degrees Celsius.

- Q: How is steel wire mesh used in the aerospace industry?

- The aerospace industry relies on steel wire mesh for a variety of purposes. One important use is reinforcing composite materials, which are commonly used in aircraft construction due to their lightweight and durable nature. However, these materials can be susceptible to delamination and cracking under stress. To address this, steel wire mesh is incorporated into the composite material to provide extra strength and prevent delamination, ultimately enhancing the overall structural integrity of the aircraft. Steel wire mesh also serves as a shield in the aerospace industry, particularly in space applications where spacecraft are exposed to high levels of radiation. It acts as a protective barrier against electromagnetic interference (EMI) and radio frequency interference (RFI), safeguarding sensitive electronic equipment and communication systems from interference. This ensures reliable and secure communication between the spacecraft and ground stations. Moreover, steel wire mesh is utilized in aerospace manufacturing processes for precision filtration and separation. It functions as a filtration medium, effectively removing impurities and contaminants from liquids and gases used in various aerospace systems, such as fuel and hydraulic fluids. Its exceptional strength and durability make it a suitable choice for these applications, enabling it to withstand high pressures and temperatures while efficiently filtering out unwanted particles. Additionally, steel wire mesh plays a vital role in ensuring safety in the aerospace industry by protecting against bird strikes. Bird strikes can cause significant damage to aircraft, including engine failure and structural harm. To prevent such incidents, steel wire mesh screens are installed in vulnerable areas like engine intakes and windows. These screens allow air to flow through while acting as a barrier against birds, guaranteeing safe and uninterrupted flight operations. In conclusion, steel wire mesh is an indispensable component in the aerospace industry. Whether it is reinforcing composite materials, shielding against electromagnetic interference, filtering impurities, or safeguarding against bird strikes, steel wire mesh contributes significantly to the safety, reliability, and performance of aircraft and spacecraft.

- Q: Can steel wire mesh be welded?

- Yes, steel wire mesh can be welded. Welding is a common method used to join sections of steel wire mesh together, providing strength and stability to the mesh structure.

- Q: Can steel wire mesh be used for gabion fences?

- Yes, steel wire mesh can be used for gabion fences. Gabion fences are structures made by filling wire mesh baskets with stones or other materials. The wire mesh acts as the framework for the gabion, providing stability and strength. Steel wire mesh is commonly used for gabion fences due to its durability and ability to withstand harsh weather conditions. It is also resistant to corrosion, which makes it a suitable choice for outdoor applications. Additionally, steel wire mesh can be easily shaped and manipulated to fit the desired design and size of the gabion fence. Overall, steel wire mesh is a reliable and practical material for constructing gabion fences.

Send your message to us

Weled trench reinforcing rebar mesh for best quanlity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords