TOWER CRANE TC4610

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 12 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technology is the drive for business development and production equipment the assurance of product quality. In the large-scale concentrated production, the stability and uniformity of product quality plays an essential role. The company constantly improves processing equipment. The automatic assembly line ensured quality stability and maximally reduced adverse effect of personal factor to the product quality. As a result, the one-time qualification rate of the products is improved and the company is able to win continuous trust from customers。

1. The lifting boom and balance boom adopt cantilever boom structure, which reduces the hoisting modular and makes it more safe, convenient and flexible to install and uninstall, and reduces the requirements for hoisting equipment and the site.

2. Multiple special mounting brackets are available, which saves the installation time and ensures safe and quality installation.

3. The lifting boom adopts cantilever boom structure and variable cross-section materials, featuring more reasonable structural stress and long service life; and it is easier to make different combination of boom length.

4. It adopts standard sections (for models of over 12t) of piece assembly structure, split structure stock, and assembled platform, which meet the transport requirements for standard container.

5. The extra-long boom is designed with a rope-supporting trolley, and the speed of which is 1/2 of that of the luffing trolley, which can achieve the most optimum rope-supporting effect. The structure has applied for national patent.

6. The lifting mechanism adopts speed regulation by frequency control or by eddy current brake series resistance, featuring good lifting performance; The slewing system adopts frequency control by torque electric motor or by coil winding type electric motor with hydraulic coupler, featuring smooth operation and small slewing impact.

7. All kinds of safety devices are reliable and easy to adjust; both the safety monitoring control system and traditional safety system are available, the double system ensures safety operation of the tower crane; the hydraulic system adopts low/medium pressure design, featuring higher safety and reliability.

The construction hoist product produced has achieved internationally advanced level in terms of industrial design, control and the drive performance, as well as the operation safety and comfortableness. And is also making efforts to keep improving the product, as what the construction hoist lifts is not only people and material, but also a kind of social responsibility and service concept…

The new generation SC series of construction hoists adopt modular structure, ergonomic design and advanced manufacturing technology, thus the adaptability and reliability of the product is greatly improved, e.g. the max. lifting height can reach 300 meters. The product adopts multiple patented technologies, reaches advanced level in China, and the market share in domestic market is increasing year by year. The product has also been exported to overseas countries like Russia, Turkmenstan, Vietnam, etc. winning the confidence of customers of both home and abroad

1. The cage drive system is equipped with buffering device, so the cage moves more stable.

2. The ergonomically designed cage interior improves comfortableness.

3. The unique structural design has applied for patent.

4. The typical technologies ensure the malposition difference of the guide rail.

5. The excellent parts in the industry ensures reliable quality of the machine.

6. Precise assembly and accurate drive.

7. Professional solutions for special projects.

8. The complete safety devices ensures reliable control system.

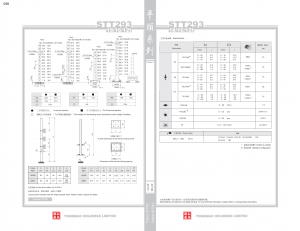

Model | Max.lifting capacity & work range | Max.work range & lifting capacity | Max.independent lifting height(m) | |||

Torque | Lifting capacity at max.boom length | Lifting capacity(t) | Work range(m) | Work range(m) | Lifting capacity(t) | |

QTZ31.5 | TC3508 | 3 | 11.59 | 35 | 0.8 | 29 |

TC3807 | 3 | 11.15 | 38 | 0.7 | 29 | |

QTZ40 | TC4208 | 4 | 11.6 | 42 | 0.8 | 29 |

TC4708 | 4 | 13.4 | 47 | 0.8 | 29 | |

QTZ50 | TC4610 | 5 | 11.9 | 46 | 1 | 36 |

TC5010 | 5 | 13.1 | 50 | 1 | 36 | |

QTZ63 | TC5013 | 6 | 13.72 | 50 | 1.3 | 40 |

TC5013A | 6 | 13.72 | 50 | 1.3 | 40 | |

TC5510 | 6 | 13.17 | 55 | 1 | 40 | |

TC5510A | 6 | 13.17 | 55 | 1 | 40 | |

QTZ80 | TC5512 | 8 | 12.68 | 55 | 1.2 | 45 |

QTZ100 | TC6013 | 8 | 14.45 | 60 | 1.3 | 45 |

QTZ125 | TC6014A | 10 | 12.4 | 60 | 1.4 | 50 |

QTZ160 | TC6020 | 10 | 15.2 | 60 | 2 | 52.6 |

QTZ250 | TC7030 | 12 | 20.4 | 70 | 3 | 45 |

- Q: What is YOUR take on Louis Crane's idea of meduso-anthropic principle?

- Well Im not into quantum physics much these days, but in his book Life and Light Lee Smolin proposes that if the quantum theory of gravity has two special features the universe would fine tune itself! If we perturb a Kerr-Newmann black hole so that the new universe will really form on the other side, and that the constants of nature might fluctuate in such a process so that the new universe would have sightly different physics than our own. Its well over my head at this stage; cause Im just an N.Y.U.K. graduate! NYUK NYUK NYUK Anyone wants to read up on it can go to the link below.

- Q: Please try to give information on the questions bellow: .What the climate was in the Japanese Crane's habitat (high, lows, averages, precipitation) . Plants in the Japanese crane's habitat .2-3 major animals in its habitat .2-3 minor animals in its habitatTHANK YOU SO MUCH!!! .

- in the east Hokkaido, the north island of japan. some japanese crane in russia goes to north korea in winter, but cranes in hokkaido stay all through the year.

- Q: I've heard that if one were to make 1000 paper cranes, then they would get one wish. Is this true?I've been making paper cranes for a few days now.

- it's true that there is a belief in folklore that making 1000 paper cranes is lucky,or grants a wish. I can't testify to the actual truth of the folklore as I have never made 1000 cranes,but on the surface, it would not seem to follow the laws of probability or physics.

- Q: I recently read that adult crane flies consume nectar or do not eat at all, their only purpose is to mate. After a crane fly mates, is starvation the cause of its death, or is there something else that ends its life such as age?

- Most adult crane flies do not have functioning mouth parts so they are unlikely to feed even on nectar. Once they have mated they quickly become the prey of birds, spiders, etc, and their corpses are also cleared up by ants and so on. Certainly they don't survive for long.

- Q: What should be included in the disassembly plan of the tower crane?

- - 1 -Contents and requirements of special construction plan for tower crane installation1. General situation of Engineering; 2, installation location and elevation plane3. The type, performance and technical parameters of the tower crane selected4,; foundation and attachment device set(1)The foundation of tower crane and the bearing capacity of its foundation shall comply with the product specificationRequirements for books and design drawings. Before installation, the foundation shall be checked and accepted before installation. There should be drainage facilities around the foundation.(2)Attached tower crane is used, the attachment device and set freeThe end height shall comply with the requirements of the product manual. When adhering to a horizontal distance or attachmentThe design calculation and drawing system should be carried out when the spacing is not satisfied with the requirements of the product specificationDrawing and writing relevant instructions shall be examined and approved by the technical leaders of the enterprise or through the originalManufacturer confirmation. Attachment device and component shall be the original manufacturer or by embedded partsEnterprise with corresponding ability to make. Attachment device design, the main structure of the building to support the checking.5, climbing conditions and adhesion node detail;The foundation, anchor and climbing support structure of an internal climbing tower crane shall be used as the foundationAccording to the product manual to provide the design calculation, and the internal climbing tower crane bearing structure checking.6, the main components of the weight lifting and installation position.7, the installation of auxiliary equipment; the type, performance and arrangement position.8. Rigging and special tools9, set the power supply;10, the construction personnel configuration;

- Q: I alsways see projects where there are these massive cranes sitting on top of huge buildings...how they hell do they get them up there?

- The big tower cranes you see on high rise structures actually....lift themselves. Their bases sit inside square lattice support structures and can climb them. When they get to the top of the structure they raise two more half squares that are bolted together around the base of the crane and the crane can then climb into the higher structure. The process is repeated until they get to the height limit of the crane. It's pretty amazing. Sometimes the crane base remains at the bottom, but sometimes, they close the floor below and remove the base that is no longer used, and just march the whole crane up the floors. Smaller cranes can be lifted by mobile cranes that go elsewhere, but the big ones use the method above.

- Q: Could bird cranes resemble angels in appearence?

- You are free to visualize objects however you wish, lol. It takes creativity, but ANYTHING could look like an angel if you try to look at it that way hard enough.

- Q: ok, so if chad is a crane then why doesnt he stay in the mansion? he is a crane right?

- Yes he is a Crane! It turned out that he is Alistair's son by Liz and not related to Whitney in any way because Liz and Eve are only step-sisters. LOL I do believe they stay in the Crane mansion now. It hasnt been made real clear but they are there quite often, even at bedtime / night time, and she is always there to talk to Teresa whenever the blackmailer scares her. Also, his birthday party last week was at the Crane mansion wasnt it? I think they stay there now that Alistair is no longer there.

- Q: The Wayfarerby Stephen Crane The wayfarer, Perceiving the pathway to truth, Was struck with astonishment. It was thickly overgrown with weeds. Ha, he said, I see that none has passed here In a long time. Later he saw that each weed Was a singular knife. Well, he mumbled at last, Doubtless there are other roads.I understand that it is about a person taken the easy way out, but what other underlying meanings are there?

- Stephen Crane Poems

- Q: crane operator?

- is a skilled trade , not to be confused with the transportation industry!

Send your message to us

TOWER CRANE TC4610

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 12 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords