top quality tower crane with CE ISO certificate QTZ100

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Descriptions of our tower crane:

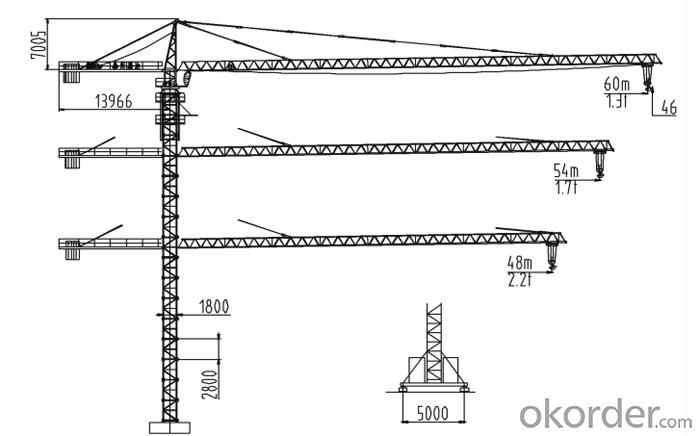

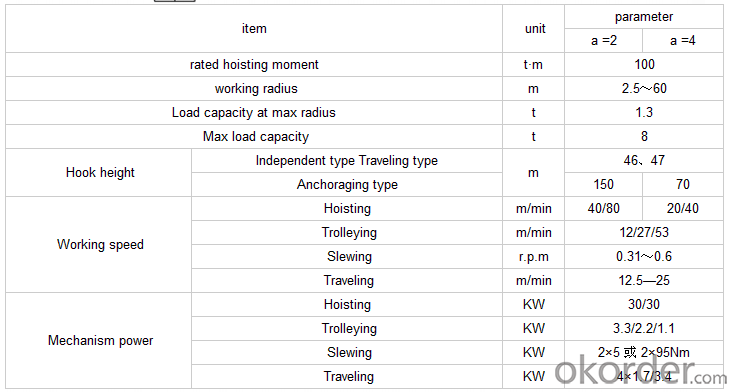

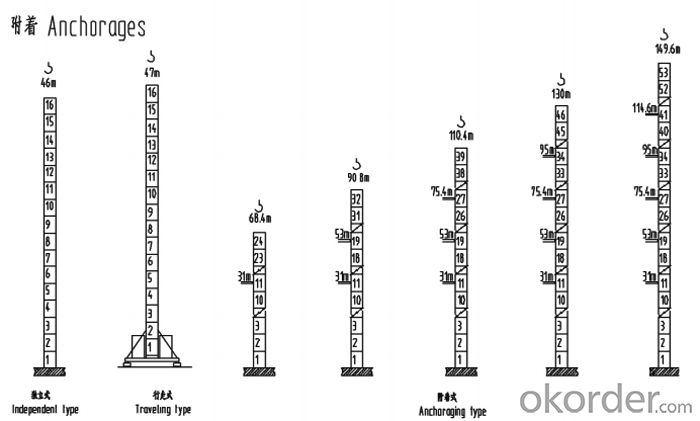

1, QTZ100 have competitive price and excellent quality, suitable for all kinds of construction project and can work under all kinds of work condition. With their working radius from 2.5m to 50m, QTZ100 tower cranes are famous for their large operating ranges, varied working methods and wide uses.

2,This series of tower cranes has a horizontal jib frame, a jib-trolley radius-changing mechanism and a hydraulic self-raising mechanism.

3, It is original in design, reliable in operation and satisfactory in shape.

4,Equipped with all necessary safety devices, these cranes show a good speed-control capacity,, satisfactory operating stability and high work efficiency.

5,They are widely applied for the construction of high-rise hotels, resident buildings, high-rise industrial buildings, large-span factory buildings and tower like buildings like tall chimneys. Best after sales service will be offered which will get rid of all your worries in the purchase of our products

Advantage of our tower crane:

1, boom relief Angle is big, greatly widened the equipment capacity and scope of work.

2, suitable for the group of tower cross homework.

3, boom stability is good, combination amplitude range.

4, suitable for height have special requirements occasions construction.

5, lifting capacity big, effectively solve the high steel structure construction team crane big lifting capacity requirements.

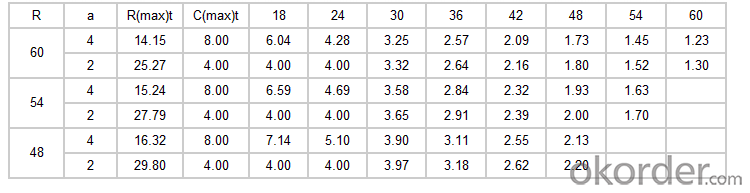

Specification of our tower crane:

- Q:where does it live? what does it eat? How do you feel about it? (positive side)thank you! thank you! thank you!help!help!help!

- In the spring and summer, the Red-crowned Crane breeds in Siberia and occasionally in northeastern Mongolia (i.e., Mongol Daguur Strictly Protected Area). Normally the crane lays 2 eggs, with only one surviving. Later, in the fall, it migrates in flocks to Korea, Japan, China, Taiwan, and other countries in East Asia to spend the winter. All Red-crowned Cranes migrate, except for a flock that is resident in Hokkaidō.

- Q:If any of you have read The Red Badge of courage by Stephen Crane can you please tell me what you think about it. Is it a good book or is it not?!!!! Do you praise it or critize it !? i need your opinion what's your review! Thanks

- The okorder /

- Q:does anyone have a good slogan for the whooping crane?

- **** the whooping crane

- Q:How to distinguish self lifting tower crane with counterweight and lifting tower crane without counterweight

- 1 self lifting tower cranes with counterweight are common tower cap tower cranes, plate type tower cranes and flat head tower cranes, characterized by a counterweight made of several concrete on the balance arm,

- Q:When the tower crane top height is more than meters

- Circular of the Ministry of housing, urban and rural construction on Issuing the measures for the safety administration of sub hazardous and sub divisional projectsAnnex No. [2009]87 [Annex two]"More than a certain size of the risk of larger sub sub project scope."

- Q:Why do you think children all over the world still fold paper cranes and send them to Hiroshima? Please answer c:

- I think she died.

- Q:because i have this huge sofa i need to get to 2nd floor but i cant coz the staircase is too small

- Talk to a lumber yard that has a boom truck. Ask them how much to do it. A boom truck will cost much less than a crane. A boom truck can reach 45 to 50 feet. In this economy they are looking for anything they can get. They will most likely do it. But when really busy they wont. But things are slow. Builder 30 years. A crane will cost about 250.00 of the first hour. with a one hour min.

- Q:I was wondering if anyone knows what period this book is set in? I know that it's set in the slums of New York and the story was published in 1893. But what time period does the story actually take place?

- hah ha i'm in your class too :) This project sucks... and I still haven't done it! I have to tonight..

- Q:The mobile crane has a weight of 116kip and center of gravity at G1; the boom has a weight of 29kip and center of gravity at G2. Determine the smallest angle of tilt θ of the boom, without causing the crane to overturn if the suspended load is W = 38kip . Neglect the thickness of the tracks at A and B. Determine the smallest angle of tilt θ of the boom, without causing the crane to overturn.

- The key here is to simplify this as much as possible The equation is really: mass 1 x length 1 + mass 2 x length 2 = mass 3 x length 3 G1 * 6 ft = (G2 * X ft) + H3 * X ft) G1 = 116 kip G2 = 29 kip H3 = 38 kip Now it is an equilibrium of torque about the point where the boom pivots: 116 kip * 6 ft = 29 kip * Xft + 38 kip * Xft solve for X feet: X feet = 10.388 ft So the crane is in equilibrium when the load is length1 + length 2 times the mass = mass of motor * length 3 (10.388 ft * 29 kip) + (10.388 ft * 38 kip) = 116 kip * 6 ft The boom forms a triangle with the hypotenuse equals 12ft + 15 ft = 27 ft. The bottom of the triangle is 10.388 ft + 10.388 ft = 20.776ft So we have two sides of the triangle and now just need to find the angle where the triangle forms with those two sides: cosine of angle = adjacent side / hypotenuse cosine of angle = 20.766 / 27 = 0.7691 and the arc cosine of that = 39.7 degrees So rounding it off, angle of crane = 40 degree

- Q:I give up...Somebody who understands The Decemberists please tell me what a Crane's Wife is and what the song is about. I love the song, I sing along loudly, but I don't have a clue.

- I found this on wikipedia. The Crane Wife is an old Japanese tale. While there are many variations of the tale, a common version is that a poor man finds an injured crane on his doorstep (or outside with an arrow in it), takes it in and nurses it back to health. After he releases the crane, a woman appears at his doorstep with whom he falls in love and marries. Because they need money, his wife offers to weave wondrous clothes out of silk that they can sell at the market, but only if he agrees never to watch her making them. They begin to sell them and live a comfortable life, but he soon makes her weave them more and more. Oblivious to his wife's diminishing health, his greed increases. He eventually peeks in to see what she is doing to make the silk she weaves so desirable. He is shocked to discover that at the loom is a crane plucking feathers from her own body and weaving them into the loom. The crane, seeing him, flies away and never returns.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

top quality tower crane with CE ISO certificate QTZ100

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords