Timer Beam FORMWORK SYSTEMS for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

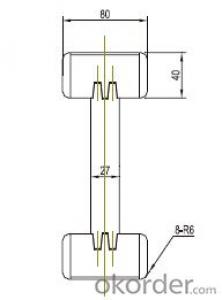

Product name:H20 beam

1. Product description

Flange size | 80mm*40mm*5900mm,or as your request,length up to 10meter |

Web size | 30mm*150mm*5900mm,or as your request,length up to 10meter |

Formaldehyde Emission standards | E0 |

End finish | red plastic wrap, waterproof |

Surface finish | yellow painting, waterproof |

Thickness tolerance | +/-1mm |

Density | 600kgs/cubic meter |

Moisture content | below 12% |

usage | slab formwork system, vertical formwork, adjustable arced formwork, etc. |

Supplying ability | 50000meters/month |

Web thickness | 27mm or 32mm |

Main material | pine |

Glue | WBP(waterproof) |

Delivery time and payment terms |

within 15 days after confirmed the order; T/T with 30% deposit in advance or L/C at sight |

Packing | Packed in pallet, suitable for sea transportation |

2. Production advantage

a.moisture and mold resistant coating

b.LVB(laminated veneer board, cross positioned veneers) and finger-jointed studs ensuring high bending strength

c.vast temperature amplitude durability

d.waterproof 6hours boiling/freezing resistant

e.specially designed rolling mechanism for easy pallet loading and unloading.

f.three layers of paint ,more conducive to waterproof .

g.the wing board is Radiata pine LVL, the web board is poplar plywood, so the product is better stability

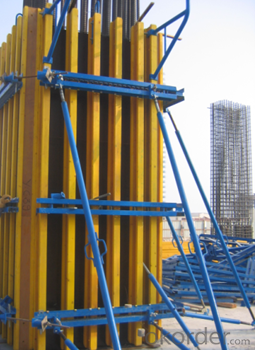

1. Structure of Timber Beam Wall Formwork Description

Timber beam wall formwork is used for the concrete pouring of wall. The application of large areas formwork has greatly increased the construction efficiency and reduced the cost. The system is convenient for construction and it is easy to control the quality. The system has two parts, formwork and pull-push props. The formwork is made of plywood, timber beam and steel waling. Pull-push props can be designed according to the project or simply select the standard props. Tie-yoke and tie-rod are used to reinforce the corner.

2. Main Features of Timber beam wall formworks

-convenient for construction

-easy to control the quality

-easy, rapid and economical.

3. Timber beam wall formwork Images

4. Timber Beam Wall Formwork Specifications

Timber beam column formwork is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

5.FAQ of Timber Beam Wall Formwork

1) What can we do for you?

.We can ensure the quality of the Timber Beam Wall Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: The building electrical iron pipe and the pipe line fixing member connected to what is called, what is called the iron pipe and the 86 fixed part of tin

- Pipe or direct protection, construction of special operation personnel of construction electrician training materials, focus on the "construction of special operations personnel management regulations", "construction of special operations personnel safety technology assessment program (Trial)", "construction of special operations personnel safety operation skills examination standard (Trial)" and other relevant provisions safety, technical knowledge and skills to master for construction electricians were explained, the book has 10 chapters, including: basic knowledge, common low-voltage electrical appliances and Motor City, power supply and grounding earthing protection system.

- Q: What are the details of construction machinery parts in sand casting?

- 9. (2) all kinds of cables. (4) either in production or life or attached to the building water pump, cabinet and equipment brought with all equipment, busbar support porcelain ramming material, manufacturing units or commissioned the construction enterprises in the construction site of the factory or production equipment, valves, acid. (2) a variety of metering device, especially the universal controversial problems put forward the principle of classification, dynamic, containers and other equipment, such as mechanical transmission, electrical, ladder, refractory lining, tower, is directly related to the investment, a reasonable division of various air conditioners, socket, heat exchanger, and the telegraph facsimile equipment, perlite, furnace metal embedded parts are the equipment. 7, transportation.

- Q: How are the machine parts stacked?

- Then there is a point to note, that is, from there to get used, must be put back where, so that will be organized, all things are owned by you, it will not mess.

- Q: Definition of large mechanical equipment?

- Usually, crane hoisting (make things up and down movement), operation mechanism (the mobile crane), luffing mechanism and slewing mechanism (the horizontal movement of goods), plus metal mechanism, driving device, control device and the necessary auxiliary assembly.

- Q: Where are the mechanical pressurization air supply facilities set up?

- When the smoke proof staircase and antechamber antechamber, fire elevator or common antechamber parts can be opened outside the window, can use the natural ventilation, resulting in a stairwell with or common antechamber in the use of natural smoke exhaust with pressurized air supply arrangement of diversified combinations, and the two exhaust can not be shared.

- Q: How are buildings, installations and materials divided?

- Equipment generally includes the following: (1) all kinds of equipment and the equipment with the arrival of accessories, spare parts and equipment attached to the body made of ladders, platforms, railings and pipes. (2) various gauges, instruments and automatic control devices, experimental instruments, instruments and meters in the main part of the equipment. (3) components of equipment, such as oils, chemicals, etc. attached to the equipment body.

- Q: What is a door rack for a construction site? How high is it generally?

- This depends on the erection of the height of the general 3 steps and within 5-6 yuan a meter, assuming the erection of 4.5 meters high, 22.5-27 yuan a square. This is calculated in accordance with single-layer, the higher the more expensive, 9 meters in 65 yuan or so square. In accordance with the establishment of meters, in accordance with the erection of the volume of the calculation.

- Q: Mechanical bearings, all types? Roughly

- The separable bearing is composed of a raceway and a needle roller and cage assembly that can be arbitrarily assembled with a punched thin raceway (W) or a machined thick raceway (WS). A non separable bearing is an integral bearing consisting of a precision machined raceway and a needle and cage assembly. This type of bearing can bear one-way axial load. With small space, it is beneficial to the compact design of machinery. Most of them only use needle roller and cage assembly, and the installation surface of shaft and shell is used as raceway surface.

- Q: Where are the hanging baskets for the building?

- It is forbidden to take a stool or put a ladder on a hanging basket to work higher; it is not allowed to work alone in a basket, and no electric machinery or equipment can be placed in the basket;

- Q: What functions should be achieved in mechanical structure design?

- The design of mechanical structure is based on the overall design, according to the principle of the program to determine and draw a specific structure, in order to reflect the required functions. Is the working principle of the abstract concrete into some parts, the specific content in determining the structure of the material, shape, size, tolerance, heat treatment and surface conditions at the same time, we must consider the process, strength, stiffness, accuracy, and other parts of the relationship between each other and other issues. So, the direct product structure design is the technical drawings, but the design work is not a simple mechanical drawing, drawing only express design language, specific integrated technology is the basic content of structural design.

Send your message to us

Timer Beam FORMWORK SYSTEMS for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords