Hanging Ceiling Grid T15 Slotted Suspension System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

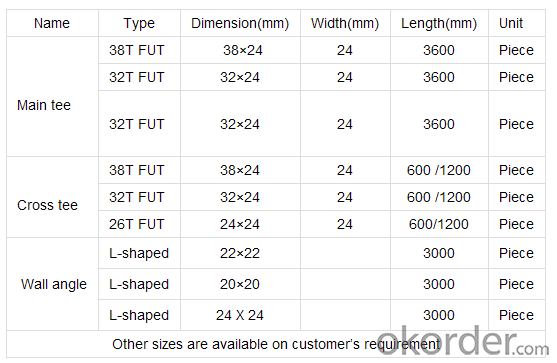

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q: Prepare the ceiling, want to know how to use light steel keel is long, such as a light steel keel is 3 meters long, and my room is 4.8 meters long, that keel is how to pick up to ensure the length of the Can I guarantee strength?

- Strength is no problem. When the keel is lengthened, pay attention to it, do not put the increase into the above or put the following, to stagger. For example, the extension of a root in the top, then it is next to the two long extension in the bottom. But also to consider the same wall of the keel through the heart to a high degree of consistency.

- Q: Fixed in the light steel keel h19 what it means

- Flat roof if the level of the width of the width of 300mm between the expansion area can be calculated by the same material can be combined with the amount of calculation, which refers to the width of the horizontal distance. The difference between the height should be the vertical height difference, the calculation of the rules described> 300mm width can be calculated by the expansion area, the expansion of the vertical height size.

- Q: does anyone know what those things are installed in commercial open-ceilings.. they are like foam materials used as insulation? I need the exact name and need to find a ceiling contractor asap, thanks !!

- I think you are reffering to what is called a drop ceiling or sometimes a grid ceiling. If that is the case the panels are made from mostly fiberglass now and some older ones are made of fiberglass and wood fibers ( cellulose ) .home depot can find a good installer at a reasonable price in your area. IF you are near northeast ct I know of several contractors that do that type of work IM me for more info

- Q: Light steel keel 38 main dragon and 50 vice dragon of the national standard thickness is owe

- I was the construction team of the ceiling wall

- Q: Asked the next ye demolition? I want to split myself. And then how to restore the floor, the walls of the hole are ye recovery? A little window also marked, we supposed to? Because it is rented house

- The hole in the material on the fill on the material chant, or the appropriate words to be a decoration to cover him There's no good way Rent the house you add light steel keel wall to do what, plus also use marble glued to the keel ah, Tile hole the most troublesome, if the landlord did not comment on the use of marble rubber tonic color patch can see if The wall must be re-brush about, not just the hole, there must be rust and the like

- Q: Light steel keel will rust deformation

- There are good quality there are poor, in fact, there are many are so iron to buy the time to buy can not buy cheap

- Q: Is there any requirements regarding hard wired smoke detectors on a suspended ceiling?I know luminaires are supposed to be properly secured to the grid, do smoke and CO detectors need to be? If so how?Right now, all I have is some old work boxes for the splices.I'm looking for a correct answer, I'm not going to cut corners.NEC code references are a plus.

- Not sure what they are called but they make a bar that goes from grid to grid with a clip on each end that you can mount a 4square box to in a drop ceiling call your local elec supply Store they will know

- Q: Light steel keel wall need to do wall

- Yes, this can be moisture and paste the footsteps

- Q: Light steel keel use method

- This is the floor or roof pavement used to facilitate the decoration and lifting the structure of other equipment

- Q: Commonly used! Is the use of engineering, hope to tell, thank you!

- Light steel: refers to the use of relatively small steel made of steel, it is characterized by relatively light, but the hardness is great.

Send your message to us

Hanging Ceiling Grid T15 Slotted Suspension System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords