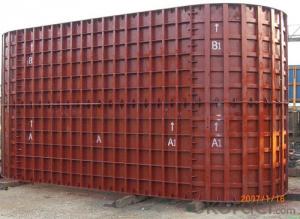

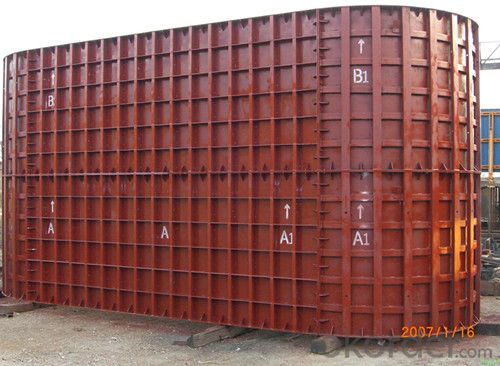

Steel Form for Common Building with Smooth Surface of Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q: How does steel formwork handle different concrete surface reflectivity?

- Steel formwork is highly versatile and can easily handle different concrete surface reflectivity. The smooth and rigid nature of steel allows it to provide a consistent and even surface for concrete placement, regardless of the reflectivity of the concrete. This ensures that the concrete surface is uniform and free from any distortions or irregularities caused by variations in reflectivity. Additionally, steel formwork can be adjusted or modified to accommodate specific requirements, providing a reliable solution for handling different concrete surface reflectivity.

- Q: Can steel formwork be used for both single-sided and double-sided forming?

- Steel formwork is capable of being utilized for both single-sided and double-sided forming. Renowned for its strength and durability, steel formwork is well-suited for various construction applications. In the case of single-sided forming, the steel panels are firmly secured against a solid surface or pre-existing structure, acting as a barrier to retain the concrete until it solidifies. Conversely, for double-sided forming, steel formwork panels are employed on both sides of the concrete pour, creating a mold that holds the concrete in place and provides a sleek finish on both sides of the structure. The versatility of steel formwork permits its utilization in a wide array of construction projects, encompassing walls, columns, beams, slabs, and more.

- Q: Can steel formwork be used for both above-water and underwater structures?

- Yes, steel formwork can be used for both above-water and underwater structures. Steel formwork is known for its durability, strength, and resistance to corrosion, which makes it suitable for various construction applications. It can withstand the water pressure and provide a stable framework for both above-water and underwater structures.

- Q: Can steel formwork be used for complex architectural designs?

- Yes, steel formwork can be used for complex architectural designs. Steel formwork offers high strength and durability, allowing it to withstand the pressure exerted by complex architectural designs. Additionally, its versatility allows for intricate shapes and designs to be achieved with precision and accuracy.

- Q: What is the maximum load that steel formwork can support?

- The maximum load that can be supported by steel formwork relies on various factors, including the thickness and quality of the steel, the formwork's structural design and configuration, and the supporting structure to which it is attached. Typically, steel formwork is built to endure substantial loads and is commonly employed in high-rise construction ventures. Nevertheless, it is crucial to review the manufacturer's specifications and engineering calculations to ascertain the precise maximum load capacity for a specific steel formwork system. Moreover, the maximum load capacity can also be influenced by the type of concrete poured, the duration of the load, and any dynamic forces that may arise during construction. To ensure safety and the structural soundness of the project, it is advisable to consult a qualified engineer or structural designer who can evaluate the specific requirements of the construction undertaking and provide accurate load capacity information regarding the steel formwork being utilized.

- Q: How does steel formwork handle different concrete finishes?

- Steel formwork is a popular choice in construction due to its durability and versatility. When it comes to handling different concrete finishes, steel formwork has proven to be highly effective. One of the key advantages of steel formwork is its smooth and rigid surface. This allows for a wide range of concrete finishes to be achieved with ease. Whether it is a smooth finish, textured finish, or even an exposed aggregate finish, steel formwork can handle them all. For smooth finishes, the steel formwork provides a level and even surface, allowing the concrete to be poured and finished seamlessly. The smooth surface of the steel formwork also helps in achieving a high-quality finish with minimal imperfections such as air pockets or surface blemishes. In cases where textured finishes are desired, steel formwork can easily accommodate various textures. This can be achieved by using specialized liners or inserts that are fixed to the steel formwork. These liners or inserts create the desired texture on the surface of the concrete as it sets, resulting in a textured finish. Additionally, steel formwork can handle exposed aggregate finishes exceptionally well. Exposed aggregate finishes involve exposing the aggregates (such as stones or gravel) in the concrete mix to create a decorative and textured surface. Steel formwork with its smooth surface allows the aggregates to be evenly distributed and exposed when the concrete is finished and cured. Moreover, steel formwork is known for its reusability. This means that it can be used multiple times without compromising its structural integrity or surface quality. This reusability factor makes steel formwork a cost-effective choice for handling different concrete finishes as it can be reused for various projects. In conclusion, steel formwork is highly versatile and can handle different concrete finishes effectively. Its smooth and rigid surface allows for a range of finishes to be achieved, including smooth, textured, and exposed aggregate finishes. Additionally, the reusability factor of steel formwork makes it an economical choice for contractors and construction projects.

- Q: What are the common design considerations for steel formwork in cold climates?

- In cold climates, there are several common design considerations for steel formwork that need to be taken into account. These considerations are crucial to ensure the structural integrity, safety, and efficiency of the formwork system in such extreme weather conditions. 1. Material Selection: Choosing the appropriate steel grade is essential to ensure the formwork's ability to withstand low temperatures without compromising its strength. High-quality steel with good cold resistance properties should be selected to prevent brittleness and potential failure. 2. Insulation: Incorporating insulation materials into the design can help minimize heat loss during concrete curing. Insulating the formwork walls and base can prevent freezing, which may lead to cracking and reduced structural integrity. 3. Thermal Expansion: Cold temperatures can cause steel to contract, which may result in misalignment and buckling of the formwork. To accommodate thermal expansion and contraction, expansion joints or flexible connections should be included in the formwork design. 4. Anchoring and Support: Cold climates often experience freeze-thaw cycles, which can generate significant ground movement. Proper anchoring and support systems must be incorporated into the formwork design to ensure stability and prevent shifting or settling. 5. Durability and Corrosion Resistance: Cold and humid environments can accelerate corrosion of steel. Incorporating corrosion-resistant coatings or galvanizing the steel formwork can enhance its durability and prolong its lifespan. 6. Load Capacity: Cold climates are frequently associated with heavy snowfall. The formwork design should consider the additional loads imposed by accumulated snow on the structure to prevent overloading and potential collapse. 7. Fastening Systems: Cold temperatures can affect the performance of fastening systems, such as bolts and screws. Using appropriate fasteners that can withstand low temperatures and prevent loosening due to thermal contraction is crucial. 8. Ease of Assembly and Dismantling: In cold climates, it is important to consider the ease of assembly and dismantling of the formwork, as extreme temperatures may hinder construction activities. Designing the formwork system with easy-to-use connections and fasteners can improve efficiency and reduce construction time. By considering these common design considerations, engineers and designers can ensure that steel formwork in cold climates is safe, reliable, and capable of withstanding the harsh conditions.

- Q: How does steel formwork compare to other formwork materials in terms of durability?

- Steel formwork is highly regarded for its exceptional durability when compared to other formwork materials. Steel is known for its strength and resilience, making it a reliable choice for construction projects that require long-lasting formwork. Unlike materials like wood or plastic, steel formwork is resistant to warping, cracking, and rotting, ensuring its longevity and effectiveness over time. Additionally, steel formwork is highly resistant to the elements, including harsh weather conditions and exposure to chemicals. It can withstand heavy loads and pressures, making it suitable for projects that involve high-rise buildings, bridges, or other structures that require robust support during the construction process. Furthermore, steel formwork offers the advantage of being reusable. After a concrete pour, steel formwork can be easily dismantled, cleaned, and reassembled for future use. This reusability factor not only reduces construction waste but also proves to be cost-effective in the long run. However, it is important to note that steel formwork requires regular maintenance to prevent corrosion. Proper cleaning, rust removal, and application of protective coatings are necessary to ensure the formwork's durability and extend its lifespan. In summary, steel formwork outperforms other formwork materials in terms of durability due to its strength, resistance to various elements, and reusability. While it requires maintenance to prevent corrosion, steel formwork remains a preferred choice for construction projects that demand long-lasting and reliable formwork solutions.

- Q: How does steel formwork handle different concrete segregation tendencies?

- Steel formwork is highly effective in handling different concrete segregation tendencies due to its strength and durability. It provides a rigid structure that minimizes the risk of concrete segregation during the pouring and curing process. The smooth surface of steel formwork prevents the accumulation of excess water or aggregates, reducing the chances of segregation. Additionally, steel formwork can be easily adjusted and reinforced to accommodate varying concrete placement methods, ensuring uniform distribution and minimizing the potential for segregation.

- Q: What are the components of a steel formwork system?

- A sturdy and efficient construction formwork is typically created by a steel formwork system, which is composed of several components. These components include: 1. Steel Panels: The primary element of a steel formwork system is high-quality steel panels, available in various sizes and shapes. These panels are designed to withstand the pressure exerted by the concrete during pouring. 2. Steel Walers and Soldiers: To enhance strength and stability, steel walers connect the steel panels horizontally, while soldiers support the steel panels vertically, preventing bulging or deformation under the weight of the concrete. 3. Tie Rods: Threaded rods called tie rods are used to secure the steel panels and walers together. These rods pass through holes in the panels and are secured with nuts and washers. They help maintain the formwork system's structural integrity and resist outward pressure from the wet concrete. 4. Formwork Accessories: To improve efficiency and ease of use, several accessories are used in conjunction with steel formwork systems. These accessories include formwork clamps, pins, cones, and wedges. They ensure alignment and secure the formwork components, preventing any movement during concrete pouring. 5. Formwork Braces: Steel diagonal members known as formwork braces provide additional support and stability to the formwork system. They are installed at regular intervals to prevent sagging or buckling of the formwork. 6. Formwork Joints: Formwork joints connect different sections of the steel formwork system. Depending on the construction project's requirements, these joints can be temporary or permanent. Temporary joints are typically used for modular formwork systems, allowing for easy assembly and disassembly. In summary, a steel formwork system is a durable and robust solution for constructing concrete structures. Its components work together to create a strong and reliable formwork that can withstand the pressures exerted during concrete pouring.

Send your message to us

Steel Form for Common Building with Smooth Surface of Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords