Stainless steel pipe #316 durable Construction engineering green energy safety

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

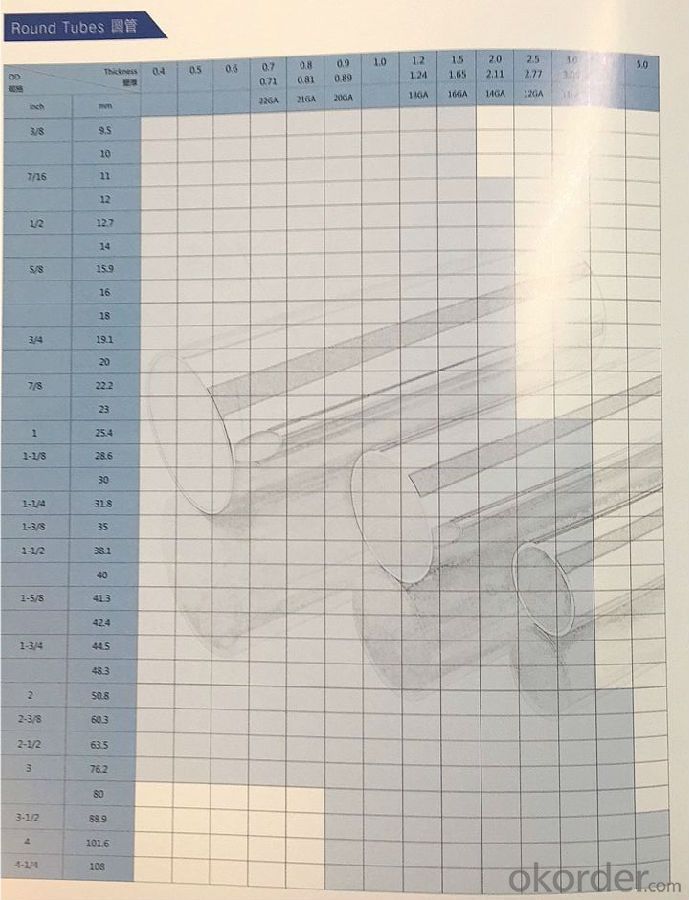

Specification

Our Company has more than 10 years experience in manufacturing and exporting stainless steel pipe and has exported to more than 50 countries and regions. We specializes in manufacturing stainless steel round tube,square tube, retangular tube, oval tube,slot tube and other special shape tube, which are of exquisite workmanship and quality is above industry level. We have several material grade of 201,202,304,304L,316,316L for you choose .

If any inquiry of stainless steel pipe you require, please feel free to contact us to get the quotation.

Strict enforcement of ASTM standard, high welding strength,weld full,non-porosity,free of crack,suitable for tube bending.

Ensure tubes have delicate surface,high brightness and smooth touching,satin finish 180-320 grit,Bright finish 500-600grit(BA),Mirror 800 grit(8K),Which is beyond industry average level and establishes the quality benchmark of (E-PAI).

Automatic plastic bag packaging equipment,PET strap pneumatic packing tool,to dresss up each tube a premium packaging and offer safety protection.

Every tube follows strict quality control during each process,to meet the standard requirements and get 100% customers satisfaction.

Sea worth export bundle paching, dry and clean warehousing ,expert container loading.

Product Description:

Stainless steel pipe

Stainless steel pipe used for construction engineering and house decorative (Extensive )

2. Main features of stainless steel pipe

Reasonable price

High manufacturing accuracy

Good visual effect

- Q: Are steel pipes resistant to corrosion?

- Yes, steel pipes are generally resistant to corrosion due to the protective layer of oxide that forms on their surface, but their resistance can vary depending on the specific grade of steel and the environment they are exposed to.

- Q: Can steel pipes be used for underground fire sprinkler systems?

- Yes, steel pipes can be used for underground fire sprinkler systems. Steel pipes are commonly used in fire sprinkler systems due to their strength, durability, and resistance to heat and corrosion. They are suitable for underground installations as they provide reliable and long-lasting performance. Additionally, steel pipes are available in various sizes and configurations, allowing for flexibility in designing and installing underground fire sprinkler systems. However, it is important to ensure that the steel pipes are properly coated or protected to prevent corrosion and ensure their effectiveness in an underground environment. Regular inspections and maintenance are also necessary to detect any potential issues or damages to the steel pipes in order to maintain the safety and functionality of the fire sprinkler system.

- Q: Can steel pipes be used for sewage treatment plants?

- Yes, steel pipes can be used for sewage treatment plants. Steel pipes are commonly used in sewage treatment plants due to their durability, strength, and resistance to corrosion. They are suitable for transporting sewage, wastewater, and other fluids in these facilities.

- Q: How do steel pipes handle extreme weather conditions?

- Steel pipes are highly durable and can withstand extreme weather conditions. They have excellent resistance to corrosion, making them suitable for humid and coastal areas. Additionally, steel pipes can withstand high temperatures, making them reliable in extreme heat or cold. Their strength and resilience make them ideal for various applications, including oil and gas pipelines, water supply systems, and construction projects in harsh weather environments.

- Q: What are the advantages of using steel pipes in the manufacturing of appliances?

- There are several advantages of using steel pipes in the manufacturing of appliances. Firstly, steel pipes are extremely durable and can withstand high pressures, making them ideal for applications that require strength and resilience. Secondly, steel pipes have excellent corrosion resistance, ensuring that the appliances will last longer without succumbing to rust or degradation. Additionally, steel pipes have a smooth interior surface, which minimizes friction and allows for efficient flow of fluids or gases within the appliances. Lastly, steel pipes are readily available and cost-effective, making them a practical choice for appliance manufacturers.

- Q: How are steel pipes protected during transportation?

- To ensure the safety and integrity of steel pipes during transportation, various measures are taken. One effective approach involves applying protective coatings to the pipes' exteriors. These coatings, such as epoxy or polyethylene, act as barriers against moisture, corrosion, and physical damage. Additionally, bundling the pipes together and securing them with strapping or bands prevents movement and potential collisions while in transit. To provide extra protection against impact and handling, wooden crates or containers may also be used. Furthermore, careful loading and unloading procedures are followed to minimize stress or strain on the pipes. By implementing these protective measures, steel pipes can safely reach their destination without compromising their quality or structural integrity.

- Q: Which is cheaper, angle iron or steel pipe?

- Steel tube (Steel pipe) production technology development began in the bicycle manufacturing industry, the rise of the early nineteenth Century during the oil development, the two world war ships, boilers, aircraft manufacturing, manufacturing of power boiler after the Second World War, the development of chemical industry of petroleum and natural gas drilling and transportation, will effectively promote the the yield and quality of varieties, the development of steel tube industry.Steel pipe is not only used to transport fluid and powder solid, exchange heat energy, and manufacture mechanical parts and containers, but also is an economic steel. It can reduce weight and save 20 to 40% of metal by using steel pipe to make building structure, network frame, prop and mechanical support. Moreover, it can realize factory mechanization construction. Using steel pipe to manufacture road bridge can not only save steel, simplify construction, but also greatly reduce the area of coating protective layer, save investment and maintenance cost.

- Q: What are the uses of seamless steel tubes?

- A large number of pipes used for conveying fluids, such as pipelines for transporting petroleum, natural gas, gas, water, and certain solid materials.

- Q: How are steel pipes used in the manufacturing of food processing equipment?

- Steel pipes are commonly used in the manufacturing of food processing equipment due to their durability, strength, and resistance to corrosion. These pipes are used to transport various food products such as liquids, powders, and gases within the equipment. They are also utilized in the construction of frames, supports, and structures for food processing machinery, ensuring stability and longevity. Additionally, steel pipes are often employed in the creation of heat exchangers, which are crucial for heating or cooling purposes in food processing equipment.

- Q: How are steel pipes used in seaport infrastructure?

- Steel pipes are commonly used in seaport infrastructure for various purposes such as constructing piers, wharfs, and docks. They are used for the foundation of these structures, providing stability and strength. Steel pipes are also used in the construction of underwater pipelines for transporting oil, gas, and other fluids. Additionally, they are utilized in the fabrication of fences, barriers, and railings to ensure safety and security within the seaport area.

Send your message to us

Stainless steel pipe #316 durable Construction engineering green energy safety

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords