Electtic Resistance Welded steel Pipe ERW Oil Pipes Factory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

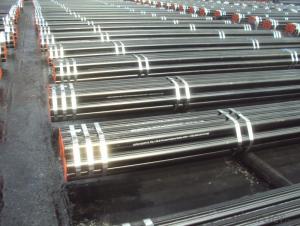

1、Structure of Seamless Pipe ASTM A106/53:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

Payment Terms: L/C D/A D/P T/T

Packing and shipment

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 Specification:

| Thickness: | 1.5 - 14 mm | Section Shape: | Round | Outer Diameter: | 21 - 219 mm |

Place of Origin: | Tianjin China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Structure Pipe |

| Technique: | Cold Rolled | Certification: | ISO | Surface Treatment: | oiled |

Special Pipe: | EMT Pipe | Alloy Or Not: | Non-alloy | Wall thickness: | thin wall pipe |

| Grade: | Q195,Q195-Q345 | Standard: | BS ,JIS G3101,DIN 2444,BS,JIS,DIN,API 5L |

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Seamless Pipe ASTM A106/53 Images:

- Q: How are steel pipes used in the construction of wastewater treatment plants?

- Steel pipes are used extensively in the construction of wastewater treatment plants for various purposes. They are used for the transportation of wastewater from one unit to another, as well as for the distribution of treated water to different areas. Steel pipes are also used in the construction of the main water supply and drainage systems within the plants. Additionally, they are utilized for the installation of pumps, valves, and other equipment required for the treatment process. The durability and strength of steel pipes make them an ideal choice for the demanding and corrosive environment of wastewater treatment plants.

- Q: Does seamless steel tube have a bend of 135 degrees?

- In engineering, it is usually marked as "45 elbow" and has no "135" mark. The angle of the elbow is acute, so there will be no more than 90 degrees elbow.

- Q: How do steel pipes handle extreme temperatures?

- Steel pipes can handle extreme temperatures due to their high strength and thermal stability. The properties of steel, such as its excellent heat resistance and low thermal expansion, allow it to withstand both high and low temperatures without significant deformation or structural damage. Additionally, the use of specialized coatings and insulation can further enhance the heat resistance of steel pipes, making them suitable for a wide range of applications in extreme temperature environments.

- Q: How do you calculate the pipe deflection for steel pipes?

- To determine the pipe deflection of steel pipes, various factors must be taken into account. Pipe deflection refers to the bending or displacement that occurs when a load is applied. The following steps outline the process for calculating pipe deflection: 1. Obtain the steel pipe properties: Familiarize yourself with the material properties of the steel pipe, including its Young's modulus (E) and moment of inertia (I). Young's modulus denotes the material's stiffness, while the moment of inertia measures its resistance to bending. 2. Identify the applied load: Determine the nature and magnitude of the load that will be exerted on the pipe. This may encompass internal pressure, external loads, or thermal expansion. 3. Utilize the appropriate formula: Depending on the load type and pipe support conditions, the suitable formula must be employed to calculate the deflection. For instance, if the pipe is simply supported (fixed at both ends), the formula δ = (5 * w * L^4) / (384 * E * I) can be used. Here, δ represents the deflection, w signifies the load per unit length, L denotes the pipe length, and E and I refer to the previously mentioned material properties. 4. Input values and compute: Insert the load, pipe length, and material properties into the formula. By doing so, the deflection of the steel pipe can be determined. It is crucial to note that calculating pipe deflection is a complex procedure that necessitates expertise in structural engineering. Therefore, it is advisable to consult a professional engineer or employ specialized software for accurate and reliable results.

- Q: How do steel pipes handle ground freezing and thawing?

- Steel pipes are highly resistant to ground freezing and thawing due to their inherent strength and durability. They are designed to withstand extreme temperature variations without significant damage or deformation. Additionally, steel pipes have low thermal conductivity, meaning they do not transfer heat as easily as other materials, allowing them to maintain their structural integrity even in freezing conditions. Thus, steel pipes are an excellent choice for underground infrastructure and can effectively handle ground freezing and thawing.

- Q: How are steel pipes used in the telecommunications sector?

- Steel pipes are commonly used in the telecommunications sector for various purposes. Firstly, steel pipes are used as conduit for underground cable installations. These pipes provide protection and support to the fiber optic cables that carry data and voice signals across long distances. The sturdy nature of steel pipes ensures that the cables remain safe from external factors such as moisture, rodents, and accidental damage. Additionally, steel pipes are used in the construction of telecommunication towers and masts. These structures require a strong and durable material to support the weight of antennas, transmitters, and other equipment. Steel pipes, with their high tensile strength and resistance to harsh weather conditions, are ideal for this purpose. Moreover, steel pipes are used for the installation of overhead communication lines. These lines are often suspended between poles or towers, and steel pipes are used as supports or brackets to hold the cables in place. The corrosion-resistant properties of steel make it a reliable choice for outdoor installations that are exposed to the elements. In summary, steel pipes play a crucial role in the telecommunications sector by providing protection, support, and durability to cable installations, tower constructions, and overhead communication lines. Their strength and resistance to environmental factors make them an essential component in building and maintaining reliable telecommunications networks.

- Q: How are steel pipes used in the manufacturing of agricultural machinery?

- Steel pipes are commonly used in the manufacturing of agricultural machinery as they are strong, durable, and resistant to corrosion. They are used to create the framework and structural components of various agricultural equipment such as plows, tillers, planters, and harvesters. Steel pipes provide stability and strength to these machines, allowing them to withstand heavy loads and operate efficiently in tough farming conditions.

- Q: What is the role of steel pipes in the transportation of water?

- The role of steel pipes in the transportation of water is to provide a durable and reliable infrastructure for the safe and efficient conveyance of water from its source to various destinations. Steel pipes are known for their strength, corrosion resistance, and ability to withstand high pressure, making them ideal for water transportation systems. These pipes ensure that water is delivered to homes, businesses, and other locations, while maintaining its quality and preventing leaks or contamination.

- Q: Steel pipe is particularly long, how to clean the inner wall of the pipe so that it can be thoroughly cleaned

- High cleanliness requirements for ultrasonic cleaningUltrasonic cleaning principle: the pressure change of ultrasonic wave propagation in the liquid in the liquid cavitation phenomenon strongly, per second produced millions of tiny gas bubbles, these bubbles rapidly in large pressure under the action of not following the violent explosion, impact force and produce strong suction, enough to make the stubborn dirt quickly stripped.

- Q: What are the different types of steel pipe coatings for offshore applications?

- There are several types of steel pipe coatings that are commonly used for offshore applications. Some of the most common types include fusion bonded epoxy (FBE) coating, three-layer polyethylene (3LPE) coating, and three-layer polypropylene (3LPP) coating. FBE coating provides excellent corrosion resistance and is often used in subsea pipelines. 3LPE coating combines fusion bonded epoxy with an adhesive and a high-density polyethylene layer, offering superior mechanical protection and corrosion resistance. 3LPP coating, on the other hand, combines fusion bonded epoxy with an adhesive and a polypropylene layer, providing enhanced resistance to high temperatures and chemicals. These coatings help to protect steel pipes from corrosion, abrasion, and other environmental factors, ensuring their durability in offshore environments.

Send your message to us

Electtic Resistance Welded steel Pipe ERW Oil Pipes Factory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords