Square Billets for construction Hot Sale Deformed Billet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Square Billets for construction Hot Sale Deformed Billet

| GRADE | SIZE | APPLICATION |

Q195/ 215 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon of Square Billets for construction Hot Sale Deformed Billet

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Technology process of Square Billets for construction Hot Sale Deformed Billet

1.Heat the EVA film

2.Cover the heated EVA film on the mould(can be made from wood or aluminum)

3.Spray a coating in a certain baume degree

4.Put on the empty blask

5.Sand-up the flask and vibrate to compaction

Packaging & Delivery of Square Billets for construction Hot Sale Deformed Billet

Packaging Details:containers

Delivery Detail:Complete one set of equipment needs for three months

The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

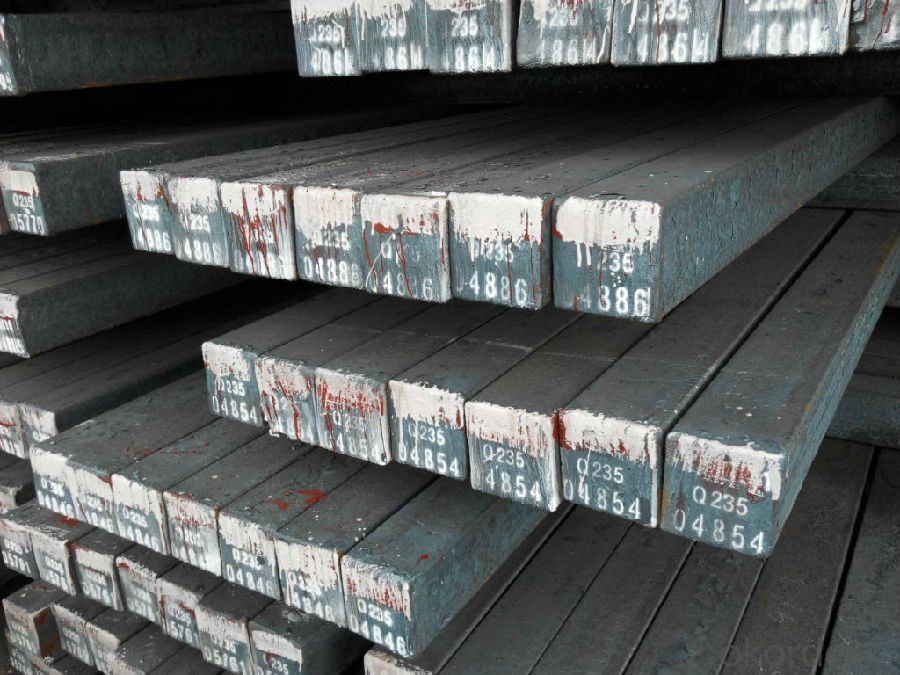

Products Show

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different forging methods used for steel billets?

- There are several different forging methods commonly used for steel billets, including open die forging, closed die forging, and upset forging. Open die forging involves shaping the steel billet between flat or shaped dies, allowing for greater flexibility in forming complex shapes. Closed die forging, on the other hand, involves placing the billet between two dies that have a pre-determined shape, resulting in a more precise final product. Upset forging is a method used to increase the diameter or thickness of the billet by compressing it axially, often used to create shorter and thicker components.

- Q: How are steel billets used in the production of agricultural components?

- Various agricultural components rely on steel billets as an essential raw material. These billets act as the foundation for the manufacturing process and are transformed into a diverse range of agricultural components, including plows, harrows, tillers, cultivators, and seeders. Initially, the steel billets are melted and cast into a solid form, usually rectangular or square, with a consistent cross-section. This solid steel piece is then heated and rolled into the desired shape and size required for the specific agricultural component being produced. After rolling and shaping the billets, they undergo further processes such as cutting, drilling, bending, and welding to create the final agricultural component. These components are specifically designed to endure the demanding conditions of the agricultural industry, including exposure to harsh weather, heavy loads, and frequent use. Steel billets offer several advantages in the production of agricultural components. Firstly, steel is a sturdy and resilient material that provides the necessary strength and durability for effective agricultural machinery operation. Additionally, steel is highly resistant to corrosion, ensuring that the agricultural components can withstand exposure to moisture, fertilizers, and other commonly used farming chemicals. Moreover, steel billets can be easily customized and fabricated into various shapes and sizes, allowing for the production of a wide variety of agricultural components tailored to specific farming needs. The versatility of steel billets also enables manufacturers to create components with intricate designs and features, enhancing their functionality and performance. In conclusion, steel billets play a crucial role in the production of agricultural components. The versatility, strength, and durability of steel make it an ideal material for manufacturing machinery and equipment used in the agricultural industry. By starting with steel billets and transforming them through various manufacturing processes, agricultural components are created that can withstand the demanding conditions of farming, contributing to the efficiency and productivity of agricultural operations.

- Q: How are steel billets cut into smaller pieces?

- Steel billets are typically cut into smaller pieces through a process called sawing or shearing. There are various methods used to achieve this, depending on the desired size and precision of the cuts. One common method is using a saw blade, either circular or band saws, which are specifically designed for cutting through metal. These saws can be manually operated or automated, depending on the scale of the operation. The billets are clamped securely to prevent movement, and the saw blade is guided along the marked cutting line, gradually slicing through the steel to create smaller pieces. Another approach is shearing, which involves using a shear machine to apply intense force to cut through the billet. This method is often used for thicker billets or when precise cuts are not necessary. The shear machine consists of a fixed blade and a moving blade that come together to sever the billet along the desired cutting line. Additionally, advanced technologies like laser cutting or plasma cutting can also be employed to cut steel billets into smaller pieces. These methods utilize high-powered lasers or plasma jets to melt or vaporize the material along the cutting line, resulting in a clean and precise cut. Overall, the choice of cutting method depends on factors such as the thickness of the billet, the desired precision of the cuts, and the production capacity. Regardless of the method used, safety precautions are always taken to ensure the well-being of the operators and to maintain the quality of the cut steel pieces.

- Q: What are the different surface treatments for corrosion resistance in steel billets?

- Steel billets can be enhanced for corrosion resistance through various surface treatments. These treatments play a crucial role in preventing rust and oxidation, which can greatly degrade the quality and lifespan of the billets. Some commonly used surface treatments for corrosion resistance in steel billets are as follows: 1. Hot-dip galvanizing: By immersing the steel billets in molten zinc, a protective coating is formed on the surface. This zinc coating acts as a sacrificial layer, safeguarding the steel against corrosion. 2. Electroplating: Through an electrochemical process, a thin layer of a corrosion-resistant metal like nickel or chromium is deposited onto the surface of the steel billet. This plated metal serves as a barrier, preventing direct contact between the steel and corrosive agents. 3. Passivation: This treatment involves the use of chemicals, usually an acid solution, to eliminate impurities or contaminants that may encourage corrosion. Passivation results in the formation of a passive oxide layer on the surface, which provides corrosion resistance. 4. Powder coating: In this method, a dry powder is electrostatically applied to the surface of the steel billet and then heat-cured. The powder melts and forms a protective layer on the steel, offering excellent corrosion resistance. 5. Organic coatings: These coatings, such as paints or varnishes, are applied to the surface of the steel billet. They create a protective barrier against moisture and corrosive agents. Organic coatings can be customized based on specific requirements in terms of color, texture, and durability. 6. Anodizing: Primarily used for aluminum or aluminum alloy steel billets, this treatment involves subjecting the surface to an electrochemical process, resulting in the formation of an oxide layer. This anodized layer enhances corrosion resistance while also providing an aesthetic appearance. Choosing the appropriate surface treatment for steel billets is crucial, considering factors like the intended application, environmental conditions, and expected lifespan. Regular maintenance and periodic reapplication of the surface treatment may also be necessary to ensure sustained corrosion resistance.

- Q: What is the difference between steel and billet in the process?

- My understanding is that..:Billet: Billet, refers to the casting of roughSquare steel: Square, Bar, the product is rolled on the basis of square billet.

- Q: What are the different types of steel billet packaging?

- There are several different types of steel billet packaging that are commonly used in the industry. 1. Bundles: Bundles are one of the most common types of packaging for steel billets. In this method, several billets are tightly bound together using steel straps or wire rods. This helps to secure the billets and prevent any movement or damage during transportation or storage. 2. Wooden crates: Wooden crates are another popular packaging option for steel billets. These crates are usually made of sturdy wooden materials and are designed to provide maximum protection to the billets. They are typically reinforced with steel bands or straps to ensure the billets remain secure. 3. Steel cages: Steel cages or racks are commonly used for packaging steel billets. These cages are made of steel and are designed to hold multiple billets at once. They provide a sturdy and secure packaging solution and allow for easy handling and transportation. 4. Plastic wrapping: In some cases, steel billets may be wrapped in plastic film or shrink wrap to provide protection against moisture and corrosion. This method is often used when the billets are being stored or transported in a controlled environment. 5. Custom packaging: Depending on specific requirements, steel billets may also be packaged in custom-made containers or packaging solutions. These can include specialized crates, boxes, or containers designed to fit the dimensions and weight of the billets, ensuring maximum protection during transportation and storage. Overall, the choice of steel billet packaging depends on factors such as the size and weight of the billets, transportation method, and desired level of protection. Each type of packaging has its own advantages and is chosen based on the specific needs of the industry and the customer.

- Q: What are the different types of steel billet forging defects?

- Some common types of steel billet forging defects include surface cracks, internal voids or cavities, improper grain flow, and dimensional inconsistencies. Other defects may include porosity, inclusions, and decarburization.

- Q: How are steel billets used in the production of forged parts?

- Steel billets are an essential component in the production of forged parts. They serve as the starting material from which the desired shape and size of the forged part is created. To begin the process, steel billets are heated to a specific temperature to make them more malleable. This temperature, known as forging temperature, allows the steel to be easily deformed without cracking or breaking. Heating the billets also improves their structural integrity and makes them more resistant to deformation during the forging process. Once the steel billets reach the desired temperature, they are placed onto a forging press or hammer. The press applies immense pressure to the billets, forcing them to take the shape of the die or mold in which they are placed. This process is known as forging and it allows for the creation of complex shapes and intricate details that cannot be achieved through other manufacturing methods. The forged parts produced from steel billets are known for their exceptional strength, durability, and resistance to wear and tear. They are widely used in various industries, including automotive, aerospace, oil and gas, and construction. Forged parts can range from small components like gears and bolts to larger items such as crankshafts, connecting rods, and turbine blades. In summary, steel billets are used in the production of forged parts by providing the raw material that is shaped and formed through the forging process. The resulting forged parts possess superior mechanical properties and are vital components in many industrial applications.

- Q: How are steel billets used in the production of aerospace parts?

- Steel billets are used in the production of aerospace parts as they serve as the starting material for forging or machining processes. These billets are heated, shaped, and then further processed to create the desired components, such as engine parts, landing gear components, or structural elements, which are crucial for the performance and safety of aerospace machinery.

- Q: How do steel billets contribute to the overall safety of a structure?

- Steel billets play a significant role in contributing to the overall safety of a structure in several ways. Firstly, steel billets serve as the raw material for manufacturing steel bars, beams, columns, and other structural components. These components are widely used in construction due to their high strength and durability. By using steel billets as the starting material, the resulting steel products exhibit excellent load-bearing capacity, which enhances the structural integrity of the building. Moreover, steel billets undergo a rigorous manufacturing process that includes various quality control checks. These checks ensure that the billets possess consistent and reliable mechanical properties, such as high tensile strength and impact resistance. As a result, when these billets are used in the construction of a structure, they contribute to its overall safety by providing a reliable and robust framework that can withstand external forces, such as wind, earthquakes, or heavy loads. Additionally, steel billets are often produced using advanced metallurgical techniques, such as controlled cooling or heat treatment, to achieve specific properties required for structural applications. These processes help in improving the microstructure of the steel, reducing internal defects, and enhancing its resistance to corrosion, fatigue, and other forms of degradation. This, in turn, increases the lifespan of the structure and minimizes the risk of structural failure, thus ensuring the safety of the occupants. Furthermore, steel billets can be manufactured with precise dimensions and tolerances, allowing for accurate and efficient construction. This precision in fabrication ensures that structural components fit together seamlessly, reducing the likelihood of gaps, misalignments, or weak points that could compromise the safety of the structure. Lastly, steel billets are highly recyclable, making them an environmentally friendly choice for construction. By opting for steel billets, the construction industry can reduce its carbon footprint and contribute to sustainable development. This focus on sustainability aligns with the overall safety of a structure, as a sustainable approach ensures the long-term stability and resilience of the built environment. In conclusion, steel billets contribute to the overall safety of a structure by providing high-strength, durable, and reliable materials for construction. Their consistent mechanical properties, resistance to external forces, improved microstructure, and precise fabrication ensure a strong and secure framework. Moreover, their recyclability promotes sustainability, further enhancing the long-term safety and integrity of the structure.

Send your message to us

Square Billets for construction Hot Sale Deformed Billet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords