Solar Panel Pole Mounting Brackets Hot Dipped Galvanized Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:SR-SCP-SERIES

Model Number:Sr-Wcp-01

Surface Treatment:Hot DIP Galvanized or Anodizing

Base:Concrete Foundation

Price:Lowest Price

Warranty:15-Year Warranty and 30-Year Service Life

Export Markets:Global

Additional Info.

Packing:Normal Package Seaworthy

Production Capacity:1000000 Watt/Watts Per Week

Specifications

1.Professional design

2.Easy to install

3.Lowest price

4.Prompt delivery

5.Suit for international standards

Product Description

PVSolver solar mounting system is designed by professional engineer team.

Widely use for MW ground mounting solar system, fast installation and save labor cost.

functions:

1. double functions. provide shade, generated the solar power and protect your cars.

2 . more types as your requirements, according to the function, we have simplify carport and waterproof canopy. according the figure, we have Double Pole, Semi Cantilever, Full Cantilever, Customized Design available.

3. fast installation, no field welding need

Only need simple tools, we can combine all mounting structure easily.

Install site:Ground

Tilt Angle:5-60deg

Max Wind Speed:<42m/s

Snow Load:<1.4KN/m2

Standard :Suit for AS/NZS 1170 and other international Standard

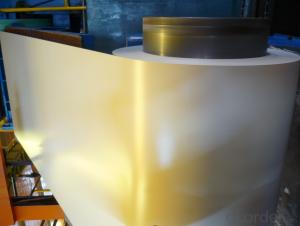

Material: U-channel steel and aluminum alloy parts or SUS304 material

Anticorrosive:Anodized aluminum & Hot galvanized U-channel steel

Soil Condition: Anyway

Warranty:15 years warranty and 30 years service life

Features,

1, Easy & Fast Installation

2, Flexible post spacing withstands different wind & snow loads.

3, High quality material in HDG steel, Aluminium 6063-T5 and SUS 304.

4, Screws and nuts go with every components needed.

5, Mechanical calculation and reliability tested to ensure highest product quality.

6, 10 years system and structural guarantee

Packaging & Shipping

Package demand: Normal package seaworthy.

All the same type U-channels will be combined one pallet, and other small parts will be loaded into the carton packaging.

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What is the maximum temperature that steel coils can withstand?

- The maximum temperature that steel coils can withstand typically depends on the grade of steel being used. However, in general, steel coils can withstand temperatures up to around 1,200 to 1,300 degrees Celsius (2,192 to 2,372 degrees Fahrenheit) before they start to lose their structural integrity.

- Q: What are the environmental considerations when using steel coils?

- Some environmental considerations when using steel coils include the extraction and processing of raw materials, energy consumption during production, and the potential for air and water pollution. Additionally, the disposal of steel coils at the end of their life cycle should also be taken into account to minimize waste and promote recycling.

- Q: Consider a steel rod of diameter 4.5 mm and length 3.3 m. If a compressive force of 4900 N is applied to each end, what is the change in the length of the rod?

- You need to calculate the stress on the rod and compare this with the mechanical properties of the steel. It would help if you were given more info. You will need to know something about the steel such as the yeild stress and E, the modulus of elasticity. The value of E is about the same for a wide range of steels. So long as the applied stress is below the yield stress, the strain is all elastic and is calculated from E. The real answer is that you can not answer this question since you do not know what the temperature is. Given the applied load, the change in length will be much different at room temperature than at 1500C.

- Q: Ok, I need two negative facts about steel wheels and two for aluminum wheels. im designing a wheel for a project in design and draw for production class. Also if you find a web site that you got the info from plz refrence it i need to write down the source of the info, but if you can't its ok. Thanks

- Negative facts for steel wheels: (1) Not as many style choices as aluminum. (2) Rust easily even when painted or powder coated, due to rock chips. (3) Heaver than aluminum, as far as fuel economy. Negative facts for aluminum wheels: (1) More sensitive to proper torquing of lug nuts. IE torque must be checked more often. (2) Susceptible to impact damage from road hazards much more than steel. (3) Need constant attention to prevent oxidation. Are these what you are looking for? I hope so. Wingman

- Q: What are the dimensions of steel coils used in automotive accessory manufacturing?

- The dimensions of steel coils used in automotive accessory manufacturing can vary depending on the specific application and requirements. However, typical dimensions for steel coils used in this industry range from 0.3 mm to 4.0 mm in thickness and from 600 mm to 2000 mm in width. The length of the coil can also vary, but it is commonly around 2000 meters.

- Q: what are the properties that can strengthen the steel to withstand earhquake?

- Some buildings are built on giant springs so they wobble when there's an earthquake but don't try to ride it out.

- Q: Is there much difference? Which is better? Are they equally safe? Is it just personal preference? Can you reccomend a good comfortable steel composite toe boot?

- steel toe boots are just that a piece of steel fitted over the toes, composite toe boots use other materials that are just as hard BUT they do not have the connectivity levels as steel. if you are working in a cold climate steel toes will freeze them toes right off, also electrical environments. my advice get a good pair of composite ones, and you get what you pay for, its worth the investment. more than you could ever imagine. proper foot support. helps legs cramps, back pain etc...

- Q: What are the different methods of blanking steel coils?

- There are several methods used for blanking steel coils, which are: 1. Shearing: This method involves cutting the steel coil into the desired size and shape using a shear or a set of shears. Shearing is a common method used for blanking steel coils as it is a fast and cost-effective process. It is suitable for cutting thin to medium-thickness steel coils. 2. Laser cutting: Laser cutting is a precise and efficient method that uses a high-powered laser beam to cut through the steel coil. It is suitable for cutting complex shapes and thick steel coils. Laser cutting provides clean and accurate cuts, making it a preferred method for high-quality blanking. 3. Waterjet cutting: Waterjet cutting uses a high-pressure stream of water mixed with an abrasive material to cut through the steel coil. This method is versatile and can cut through various materials, including steel, without generating heat. Waterjet cutting is suitable for cutting thick steel coils and is often used for intricate shapes and designs. 4. Stamping: Stamping is a method that involves pressing a die into the steel coil to cut out the desired shape. This process is commonly used for high-volume production as it can rapidly cut multiple pieces at once. Stamping is suitable for cutting simple shapes and is often combined with other processes like shearing or laser cutting for more complex shapes. 5. Plasma cutting: Plasma cutting uses a high-velocity jet of ionized gas to cut through the steel coil. It is suitable for cutting thick steel coils and can handle a wide range of materials. Plasma cutting is known for its speed and versatility, making it a popular method for blanking steel coils. These methods of blanking steel coils provide different benefits depending on the requirements of the project, such as speed, precision, complexity of shapes, and material thickness. The choice of method depends on factors like cost, production volume, desired quality, and turnaround time.

- Q: How are steel coils used in the manufacturing of suspension systems?

- Steel coils are used in the manufacturing of suspension systems as they provide the necessary support and flexibility to absorb shocks and vibrations, ensuring a smooth and comfortable ride. These coils are typically used in coil spring suspension systems, where they are compressed and stretched to absorb and distribute the weight of the vehicle, maintaining stability and enhancing overall performance.

- Q: what do we use steel for and whyand why do we use brass for instrumentsplz help its homework and i cant find the answer anywhere : (

- By instruments do you mean musical instruments? Brass is used for musical instruments because it's strong but very malleable. It's easy to hammer and roll into sheets, or form into tubes and complex shapes. It's easy to work with using hand tools. It's also very corrosion resistant and polishes very well. It has an attractive gold-like color. It also has some effect on sound, though the shape and design of an instrument is much more important to the sound than the material that's used. Apart from musical instruments, brass is used for items that need to be both durable, easy to manufacture, and resistant to the elements. For example plumbing items like valves and screw couplings.brass is a lot easier to cut with machine tools than steel. It's also traditionally used for hardware on doors and cabinets because of it's color, low friction properties, and corrosion resistance. Brass also is toxic to bacteria, and so brass doorknobs disinfect themselves after about 9 hours. Steel is very strong and very cheap. Steel is basically iron with a small amount of carbon added which makes it much stronger. Iron is the fourth most common element in the earth's crust, after oxygen, silicon, and aluminum. Brass being a mixture (an alloy) of copper and zinc, with other metals sometimes added. Copper and zinc are the 27'th and 26'th most common elements. Therefore, it make sense that brass is much more expensive than steel. Steel is used for too many things to be listed. The use of steel technology has impacts on almost every aspect of modern life. Nearly all of the man-made objects you touch on a regular basis were made using steel tools and steel machinery.

Send your message to us

Solar Panel Pole Mounting Brackets Hot Dipped Galvanized Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords