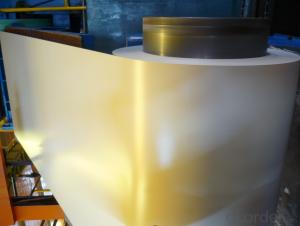

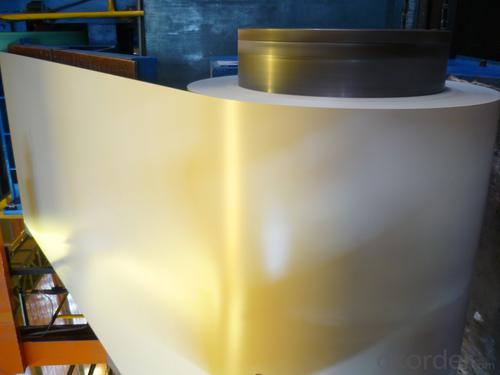

Prepainted Galvanised Steel Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Prepainted Galvanized Steel

With galvanized steel as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Brand Name: HBSTEEL

Specifications OfPrepainted Galvanized Steel

Thickness 0.20-1.2mm (BMT) Width 600-1250mm |

Zinc Coating 100-275g/m2 |

Color According to RAL color fan or as per request |

Internal Diameter 508mm or 610mm |

Coil Weight 3-6MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD,S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Prepainted Galvanized Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Applications OfPrepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

- Q: What are the different types of steel coil surface treatments for corrosion resistance?

- There are several types of steel coil surface treatments for corrosion resistance, including galvanizing, zinc coating, chromating, and polymer coating.

- Q: I'm missing the arguement, and I've seen another question like this... but the steel toe issue has 2 scenario's right?... Let me label them out, the 2nd is the one that no one talks about?Note to anyone - how are your catapillar boots, your wolverines, and then your cheap walmart/sears brands?1. Steel toe on, toes get cut off because of something falling on them. OUCH!.. Reattach perhaps?2. This one is what I question. No steel toe, large object falls on toes. SMASH... Pudding in your shoes.Wouldn't it be safer to say you'de be better off with a steel toe?

- Go to Discovery channel and look up Mythbusters episode on steel toed boots. It will surprise you what they can take, even with dropped items. They could get some damage, but never a severance.

- Q: What are the different methods of embossing steel coils?

- There are several methods of embossing steel coils, including roller embossing, heat embossing, and laser embossing. Roller embossing involves using engraved rollers to press a pattern onto the steel surface. Heat embossing uses heat and pressure to create raised designs on the steel coils. Laser embossing utilizes laser technology to etch intricate patterns onto the steel surface. These methods allow for the creation of unique textures and designs on steel coils for various applications.

- Q: How are steel coils used in the production of steel clips?

- Steel coils are used in the production of steel clips by being unwound and fed into a machine, where they are cut, shaped, and formed into the desired clip design.

- Q: Why are properties of steel not identical?

- Steel is manufactured to different specs. To match the needs of its intended end use .Tensel strength,Hardness, Corosion resistance etc. The chemical make up will change to suit.

- Q: How are steel coils processed and shaped into different products?

- Steel coils are processed and shaped into different products through a series of manufacturing processes. The first step in the process is called uncoiling, which involves unwinding the steel coil and straightening it. This is usually done by feeding the coil through a machine called a decoiler. Once the coil is uncoiled, it goes through a process called leveling. This is done to eliminate any unevenness or warping in the steel. The coil is passed through a set of rollers that apply pressure and flatten the steel to the desired thickness. This ensures that the steel is uniform and ready for further processing. After leveling, the steel is typically cut into smaller pieces or sheets. This is done using machines such as shears or slitters, which can cut the steel into different widths or lengths. The precise dimensions will depend on the requirements of the specific product being manufactured. Once the steel is cut, it can undergo additional shaping processes. One common method is called roll forming, where the steel is passed through a series of rollers that gradually shape it into the desired profile. This is often used to produce products such as roofing sheets, wall panels, or beams. Another common shaping process is called stamping. In stamping, the steel is pressed between a die and a punch to create complex shapes or patterns. This is commonly used in the automotive industry to produce components such as car body panels or engine parts. In addition to shaping, the steel may also undergo surface treatments or coatings to enhance its properties or improve its appearance. This can include processes such as galvanizing, where a layer of zinc is applied to protect the steel from corrosion, or painting to provide a decorative finish. Overall, the process of shaping steel coils into different products involves a combination of cutting, shaping, and surface treatments. These processes are carefully executed to ensure that the steel meets the required specifications and is ready for use in various industries.

- Q: Can steel coils be coated with ceramic?

- Yes, steel coils can be coated with ceramic.

- Q: Will a 8mm steel ball fired from a 150lbs crossbow kill small game and if so, from how many yards?

- Steel Crossbow

- Q: What are the different types of steel coil surface finishes?

- There are several different types of steel coil surface finishes available, each with its own unique characteristics and applications. Some of the most common types include: 1. Hot rolled: This finish is achieved by rolling the steel at a high temperature, which results in a rough and textured surface. Hot rolled steel coils are commonly used in applications where aesthetics are not a priority, such as structural or industrial projects. 2. Cold rolled: In contrast to hot rolled steel, cold rolled steel coils are processed at lower temperatures, resulting in a smoother and more refined surface. This finish is ideal for applications where a clean and polished appearance is desired, such as automotive parts, appliances, and furniture. 3. Galvanized: Galvanized steel coils are coated with a layer of zinc to protect them from corrosion. This finish provides excellent resistance to rust and can be used in a variety of outdoor applications, including roofing, fencing, and signage. 4. Stainless steel: Stainless steel coils have a unique finish that is resistant to corrosion, staining, and rust. This makes them highly versatile and suitable for a wide range of applications, including kitchen appliances, medical equipment, and architectural projects. 5. Coated: Coated steel coils are treated with a protective layer of paint or other coatings to enhance their durability and aesthetic appeal. This finish is commonly used in the construction industry for applications such as roofing, siding, and garage doors. 6. Pre-painted: Pre-painted steel coils are coated with a layer of paint or resin before they are formed into the final product. This finish offers a wide range of colors and finishes, making it popular for applications such as building cladding, appliances, and automotive parts. Overall, the choice of steel coil surface finish depends on the specific requirements of the project, including aesthetics, corrosion resistance, and durability. Each finish has its own advantages and disadvantages, and it is important to consider these factors when selecting the appropriate type of steel coil surface finish for a particular application.

- Q: What are the different methods of coil flattening for steel coils?

- There are several methods used for coil flattening in the steel industry. Some of the common methods include roller leveling, tension leveling, and stretcher leveling. Roller leveling involves passing the coil through a series of rollers to flatten it. Tension leveling uses a combination of tension and bending to remove any shape defects in the coil. Stretcher leveling stretches the coil in the lengthwise direction to eliminate any waviness or buckling. Each method has its own advantages and is used based on the specific requirements of the steel coil.

Send your message to us

Prepainted Galvanised Steel Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords