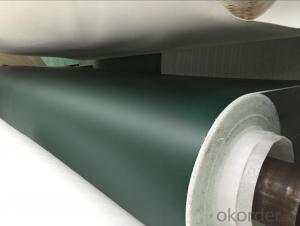

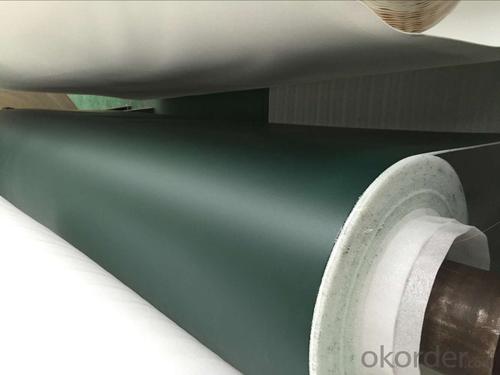

Smooth Gloss/Matt PVC/PU Conveyor Belt For Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Smooth Gloss/Matt PVC/PU Conveyor Belt For Food Industry

PVC/PU Conveyor Belt

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

Polyvinyl chloride, commonly abbreviated to PVC, is the third most widely produced plastic after polyethylene and polypropylene. Polyvinyl chloride is produced by polymerization of the monomer vinyl chloride.

PVC is widely used in construction because it is durable and easily worked. It can be made softer and more flexible by the addition of plasticizers. In this form, it is used in clothing and upholstery, electrical cable insulation, inflatable products, and many applications in which it replaces rubber.

PVC's biological and chemical resistance and workability have resulted in its use in a wide variety of applications. It is used for sewerage pipes and other pipe applications where cost or vulnerability to corrosion limits the use of metal. With the addition of impact modifiers and stabilizers, it has become a popular material for window- and door frames. By adding plasticizers, it can become flexible enough to be used in cabling applications as a wire insulator.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise (LdB belts)

* Working temperature ranges from -10 to 80Deg.C

Please contact us freely if you need any conveyor belt.

- Q: Are olive nets effective in preventing fruit fly infestations?

- Yes, olive nets are effective in preventing fruit fly infestations. These nets act as a physical barrier, preventing the fruit flies from reaching the olive trees and laying their eggs on the fruits. By keeping the flies away, olive nets help minimize the risk of fruit fly infestations and protect the crop from damage.

- Q: How long do olive nets typically last?

- Olive nets typically last for several years, with proper care and maintenance.

- Q: Do olive nets require regular maintenance?

- Yes, olive nets do require regular maintenance. These nets need to be properly installed and regularly inspected to ensure they remain in good condition. They should be cleaned regularly to remove debris and prevent damage. Additionally, any tears or holes should be repaired promptly to maintain their effectiveness in protecting the olives.

- Q: How does an olive net affect the overall crop health in the olive grove?

- An olive net can have both positive and negative effects on the overall crop health in an olive grove. On one hand, it can provide protection against pests and birds, reducing the risk of damage to the olives and improving the yield. Additionally, the net can create a microclimate that helps retain moisture in the soil, promoting healthier growth and reducing water stress. On the other hand, if not properly installed or maintained, the net can hinder air circulation, leading to increased humidity and potentially causing fungal diseases or reduced fruit quality. Therefore, it is essential to carefully assess the net's installation, maintenance, and the specific needs of the olive grove to ensure its positive impact on crop health.

- Q: Can olive nets be used for olive trees in regions with high disease incidence?

- Yes, olive nets can be used for olive trees in regions with high disease incidence. Olive nets act as a physical barrier, protecting the trees from external factors such as pests and diseases. They can help reduce the spread of diseases by preventing the entry of infected insects or pathogens, providing a layer of protection for the olive trees.

- Q: Can olive nets be used to protect against frost damage?

- Yes, olive nets can be used to protect against frost damage. These nets act as a physical barrier, preventing frost from directly touching the olive trees or plants. They help to trap heat and create a microclimate, reducing the risk of frost damage to the olive crops.

- Q: Do olive nets require any specific cleaning or washing procedures?

- Yes, olive nets do require specific cleaning and washing procedures. After use, they should be shaken to remove any debris or loose olives. Then, they can be washed with water and mild soap to remove dirt or stains. It is important to ensure they are completely dry before storing them to prevent mold or mildew growth.

- Q: What sizes do olive nets come in?

- Olive nets typically come in various sizes ranging from small to large, depending on the specific needs and requirements of olive farmers.

- Q: Can olive nets be used on trees with low branches?

- Yes, olive nets can be used on trees with low branches. However, it may require some adjustment and careful installation to ensure that the nets are properly secured and do not get tangled or hinder the access to the lower branches.

- Q: How long is the shelf life of plastic bottles?

- Pearl cotton plastic products are made of different resin materials, in different temperatures, humidity and other conditions, will release toxic substances.

Send your message to us

Smooth Gloss/Matt PVC/PU Conveyor Belt For Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords