Light Industry Green PVC/PU Conveyor Belt Smoth Gloss/Matt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

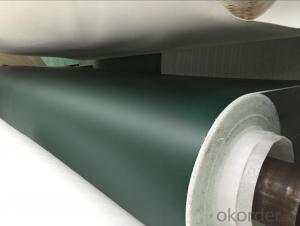

Light Industry Green PVC/PU Conveyor Belt Smoth Gloss/Matt

Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

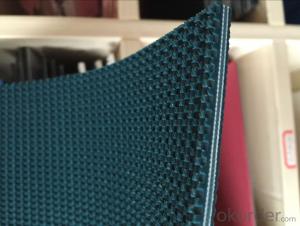

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

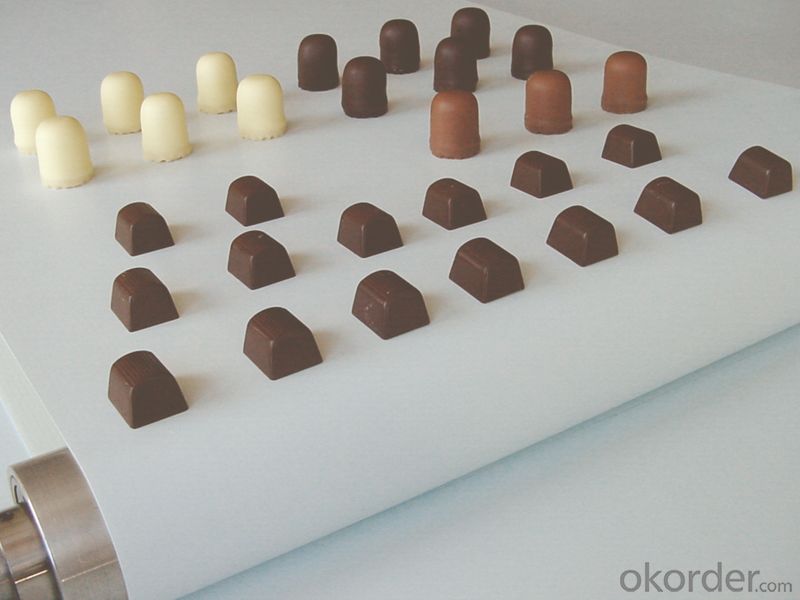

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

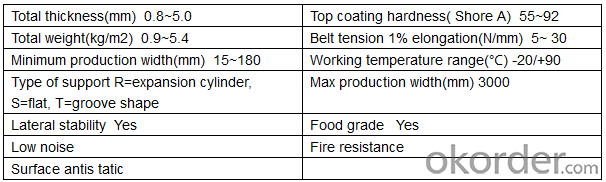

PVC Conveyor Belt Specification

Our market: we specialised in export business more than 10 years,our market spread all over the world,such as South Africa, Australia, Indonesia, Germany and so on for flat top modular plastic conveyor mesh belt.

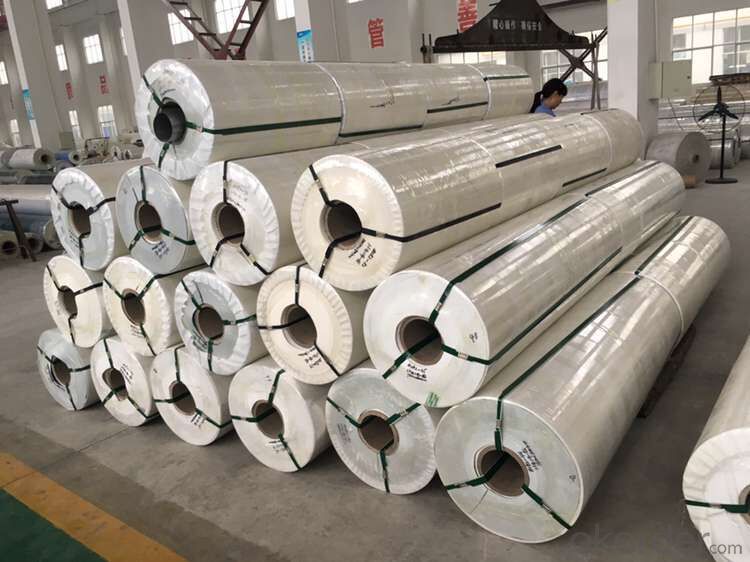

Photos of Food PVC Conveyor Belt

FAQ

Can you give me discount?

Yes, of course. If you talk with us, you’ll get more.

Will you send me free sample?

Yeah, she'd love to; can you buy her a ticket?

Do you like to accept small orders?

We enjoy to grow up together with all our clients, whatever big or small.You will become bigger and bigger to be with us.

Buyer attention

If you are interested in our products and company, please leave a message here or E-mail to us, We will reply you without any delay.

- Q: What are the different materials used to make olive nets?

- The different materials used to make olive nets include polyethylene, polypropylene, nylon, and sometimes natural fibers like jute or cotton.

- Q: What is the low temperature resistance of plastic PS?

- PS:= polystyrene (polystyrene)Material characteristics: the disadvantages are: product brittle, low impact strength, prone to stress cracking, poor heat resistance; heat resistance: 60-70 degrees, compared with other plastics, the characteristics of PS are highly transparent (light transmittance 88%-92%) and surface gloss, easy dyeing, high hardness, good rigidity in addition, there is a good water resistance, chemical corrosion resistance and processability.

- Q: What is plastic made of?

- Plastic: plastic material, the so-called plastic refers to the external force of the deformation occurs, the external force can be maintained after the abolition of the state of force. The elastic modulus of plastic is between rubber and fiber, and it can deform in a certain way. Soft plastics close to rubber, hard plastics, close to fiber.

- Q: How do olive nets help in reducing labor costs during harvesting?

- Olive nets help in reducing labor costs during harvesting by providing a more efficient and convenient method of collecting olives. These nets are spread beneath the olive trees, catching the falling olives as they are harvested. This eliminates the need for manual picking and gathering of olives from the ground, which can be time-consuming and labor-intensive. The nets make it easier to collect a larger quantity of olives in a shorter period, reducing the number of workers required for the task and ultimately lowering labor costs.

- Q: Can olive nets be used in olive groves with limited access to markets?

- Yes, olive nets can be used in olive groves with limited access to markets. Olive nets are primarily used to collect the olives during harvesting, regardless of the access to markets. The nets can aid in preventing olives from falling to the ground, reducing waste, and ensuring a higher yield. However, the actual transportation and distribution of the harvested olives to the markets may pose challenges in areas with limited access.

- Q: How do you prevent olive nets from damaging the soil or root system of the olive trees?

- To prevent olive nets from damaging the soil or root system of the olive trees, it is essential to ensure proper installation and maintenance of the nets. Prior to installation, the ground should be prepared by removing any debris or sharp objects that may puncture the nets. Additionally, extra care should be taken to avoid tightly securing the nets around the base of the trees, allowing sufficient room for growth and preventing unnecessary pressure on the roots. Regular inspection and adjustment of the nets throughout the season can help minimize any potential damage caused by rubbing or friction.

- Q: How do olive nets prevent olives from falling to the ground?

- Olive nets are designed to act as a protective barrier, preventing olives from falling to the ground during harvest. These nets are spread out beneath the olive trees, creating a catchment area that catches the olives as they detach from the branches. By catching the olives before they hit the ground, the nets eliminate the risk of damage caused by impact, soil contamination, or loss due to pests or animals.

- Q: How do olive nets affect the overall flavor of the olives?

- Olive nets do not directly affect the overall flavor of the olives. The nets are primarily used to protect the olives from birds and other pests, preventing damage to the fruit. The flavor of the olives mainly depends on factors such as the olive variety, growing conditions, maturity, and processing methods.

- Q: Can olive nets be used on olive trees grown in arid climates?

- Yes, olive nets can be used on olive trees grown in arid climates. Olive trees require protection from extreme heat and sun exposure, and using nets can provide shade and reduce evaporation, helping to conserve water and create a more favorable microclimate for the trees. Additionally, nets can prevent pests and birds from damaging the olives, ensuring a better yield.

- Q: Are there any disadvantages of using an olive net?

- Yes, there are a few disadvantages of using an olive net. Firstly, the netting can damage the branches and foliage of the olive tree if not installed properly or if it is too tight. This can lead to decreased productivity and even long-term damage to the tree. Secondly, olive nets can also trap other unintended animals and insects, such as birds or beneficial pollinators, which can disrupt the ecological balance of the orchard. Lastly, the process of installing and removing the netting can be time-consuming and labor-intensive, especially in larger olive groves.

Send your message to us

Light Industry Green PVC/PU Conveyor Belt Smoth Gloss/Matt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords