Small Hydraulic Pump 2CY Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Export standard wooden pallet or user-defined. |

| Delivery Detail: | within 7 days after recieving payment(according to order QTY) |

Specifications

Mainly used for firing boiler hydraulic aspects.

High hardness and wear property.

Stable pump pressure, little discharge.

Small Hydraulic Pump

General Purpose Pumping manufacture Small Hydraulic Pump 2CY pump

2CY Small Hydraulic Pump's Application

2CY series pump applies to delievering non-corrosive lubricating-oil or equivalent liquid without solid particles.

It applies to hydraulic system,too.

Application fields:

Oil, Petrochemical, Chemical, Mining, Metallurgy, Electricity, Shipbuilding, Textile dyeing and printing, Paper manufacturing, Construction, Medicine, Foodstaff industries, ect.

If you are looking for Small Hydraulic Pump, maybe you need it -- 2CY Gear Pump ö.ö

| Name | 2CY Small Hydraulic Pump | |

| Type | 2CY SMALL GEAR PUMP | |

| Application | •Professional hydraulic oil pump •Transfer pump or booster pump •Fuel pump •Lubricating pump | |

| Material | Pump casing | 1.Cast iron (HT200, HT250) 2.Nodular cast iron (QT450) |

| Gear | 1.40Cr 2.38CrMoAl | |

| Capacity | 1.08~12 m3/h | |

| Viscosity | 5~1500cSt | |

| Temperature | <300°c | |

| Pressure | 2.5Mpa (max pressure is 4.0Mpa) | |

| Speed | 1420~1460r/min | |

| NPSH | 9.5m | |

Suction head | 0.5m | |

| Motor type | Normal type, Explosion-proof type, Shipborne type | |

| Advantage | Higher hardness and wear property | |

| Shaft seal | Mechanical seal or packing seal | |

More Details:

| MOQ | 1SET |

| Certification | GL, ABS, BV, CE, DNV |

| Package | Standard export carton or plywood case |

| Delivery date | Within 25 working days after confirm order |

| Warranty | 1 year |

| Customized | Available |

2CY Small Hydraulic Pump

Application Scope of Small Hydraulic Pump

1.Transfer pump or booster pump in oil delivery system.

2.Fuel pump for delivery, pressurization and injection in fuel supply system.

3.As hydraulic pump supplying hydraulic power in hydraulic system.

4.As lubricating pump in all dustry field.

5.The pressure can reach up 4.0Mpa.

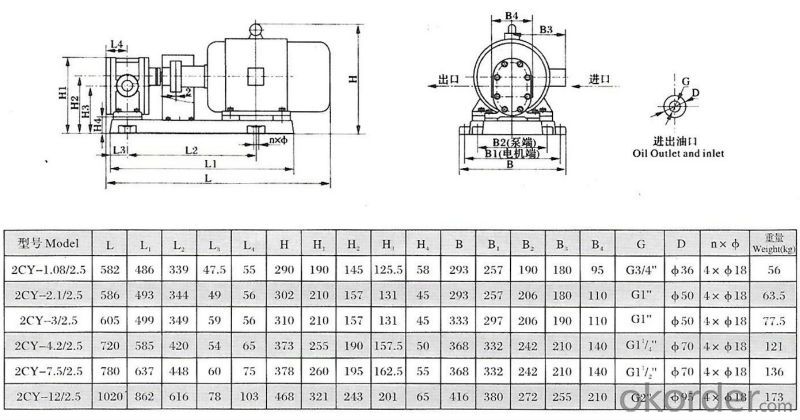

Small Hydraulic Pump Structural Diagram

Functional data

| Model | Capacity | Speed (r/min) | Exhust pressure (Mpa) | NPSH (m) | Efficiency (%) | Motor | ||

| m3/h | L/min | Power(KW) | Model | |||||

| 2CY-1.08/2.5 | 1.08 | 18 | 1420 | 2.5 | 9.5 | 58 | 2.2 | Y100L1-4 |

| 2CY-2.1/2.5 | 2.1 | 35 | 1420 | 2.5 | 9.5 | 58 | 3 | Y100L2-4 |

| 2CY-3/2.5 | 3 | 50 | 1440 | 2.5 | 9.5 | 59 | 4 | Y112M-4 |

2CY-4.2/2.5 | 4.2 | 70 | 1440 | 2.5 | 9.5 | 62 | 5.5 | Y132S-4 |

| 2CY-7.5/2.5 | 7.5 | 125 | 1440 | 2.5 | 9.5 | 63 | 7.5 | Y132M-4 |

| 2CY-12/2.5 | 12 | 200 | 1460 | 2.5 | 9.5 | 61 | 15 | Y160L-4 |

♥Dear friend, please provide me parameter of detailed information such as medium nature, capacity, pressure and meterial of pump so on. We will help choosing the most suitable pump with best quality for you.

Note:Pumps above can be matched with different motor as customer requirment.

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

- Q: You'd better point out the details.... There are 2 best ways of experience and formulaCan you say a simple point, such as multi-stage pump, when the pump is higher than the motor, 30 wire is the next mouth how to do?

- Looking forAlignment means the position of the center of rotation of the pump and motor so that they are in the same line.At least three times after the initial installation or after installation:

- Q: What are the general water pump failure, how to repair?

- (4) because of the long latent water and the corrosion of the pipe wall, the water inlet of the water inlet is constantly dropping. When the holes appear above the water, the air enters the water inlet pipe from the hole.(5) there is a crack at the bend of the inlet pipe, and there is a small gap between the inlet pipe and the water pump, which may cause the air to enter the inlet pipe.

- Q: What is a solution pump?

- 2.1 advantages of canned pumps(1) fully enclosed. There is no dynamic seal in the structure. Only the static seal in the outer shell of the pump can be made without leakage. It is especially suitable for transporting flammable, explosive, precious liquids and toxic, corrosive and radioactive liquids(2) high safety. The rotor and stator each have a shielding sleeve, so that the rotor and stator of the motor are not in contact with the material, even if the shield is broken, it will not produce the risk of leakage and leakage(3) compact structure and small footprint, the pump and motor is a whole, disassembly and assembly do not need to find the center. The base and foundation requirements are low, and the daily maintenance workload is low, and the maintenance cost is low

- Q: What are the causes of pump shock?

- 3. the water pump set screws loose, adjust the concentric, fastening the foot4. pump into foreign body, open cover overhaul5. the flow is too large or too small, adjust the equipment to control the water output

- Q: What is double hydraulic pump?

- The 2 pumps are all coaxial connected together, driven by a motor, the general gear pump, piston pump

- Q: How to install, operate and maintain the pipeline booster pump?

- The motor coil is provided with a safety protector, and when the pump is out of order or the water is not pumped, the motor can automatically break down when the temperature of the motor exceeds the prescribed value, and the motor can automatically resume operation after the temperature rise of the motor is decreased. The booster pump motor is a capacitor running type motor. When the pump leaves the factory, the rotation direction has been adjusted. If you need to replace the capacitor or re connect, press the arrow direction on the pump body to mark the connection. To ensure safety, use the three - core safety socket with ground wire.

- Q: Advantages and disadvantages of centrifugal pumps?

- Centrifugal pump; advantages and disadvantages:(1) advantages:The structure of the pump is simple and compact, and the centrifugal pump has small area, light weight, little material consumption and high cost for the foundation. Therefore, the cost of manufacturing and installation is less.For high speed operation, the 2 pole or 4 pole motor can be directly connected. The drive structure is simple and easy to install.

- Q: What is the displacement of the pump? Flow? What is the volume efficiency and mechanical efficiency of the pump?

- Mechanical efficiency: the ratio of theoretical torque to actual torque of the pump.

- Q: What is the function of the heating pump system for the water pump design?

- As the feed water temperature is higher, in the case of non warm pump start, will make the pump body is subject to greater thermal impact; in addition, the flow components with the pump contact heating fast, not contact with water directly heating slowly. This expansion due to uneven speed, it will inevitably produce thermal stress, deformation of the pump body, sealing surface, the joint surface is lax and leaking phenomenon. Therefore, the warm water pump system is designed for the water pump.

- Q: Filter backwash pump for what use, what is the principle of work ah?

- But the reverse cleaning can not completely regenerate the filter medium, or there will be some impurities remain, when the regeneration of residual impurities (pressure drop) to set the value, you need to replace the filter (filter media).

Send your message to us

Small Hydraulic Pump 2CY Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords