Silicone Rubber Coated Fiberglass Fabric for Thermal Insulation at High Temperatures

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRICE: USD12 per square meter

UNIT: square meter

MOQ: 500square meters

Width: 1m, 1.27m, 1.52m

Color: black

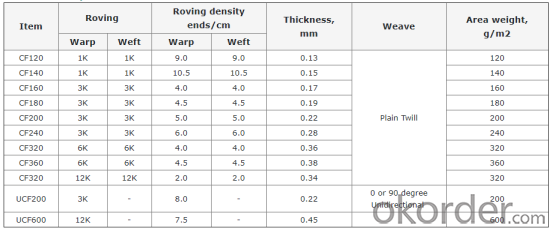

Weave Type:twill woven, plain woven

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

Description: Carbon fabric is woven by carbon fiber yarn available with 1K,3K,6K,12K, 24K. Carbon fiber is known as super high strength, modulus and light weight. It is a outstanding reinforce material. Depends on the various quality of carbon fiber, there are available various fabrics.

Features: High strength and modulus, Excellent resin and adhesive compatibility, Flexible customized specification

- Q: What are the different fiberglass fabric weaves for high strength applications?

- There are multiple fiberglass fabric weaves commonly utilized for high strength applications, including plain weave, twill weave, satin weave, and leno weave. 1. Plain weave: This weave pattern is the most fundamental and widely used. It involves an over-under pattern, with each warp yarn passing over and under each weft yarn. Plain weave fabrics offer exceptional strength and dimensional stability, making them appropriate for a wide range of high strength applications. 2. Twill weave: Twill weave is characterized by a diagonal pattern formed by the interlacing of warp and weft yarns. This weave is renowned for its strength and durability. Twill weave fabrics possess good drapability, making them ideal for applications requiring flexibility and resistance to wrinkling. 3. Satin weave: Satin weave is identified by long floats, where the warp or weft yarns skip over multiple yarns in the opposite direction. This creates a smooth and glossy surface. Satin weave fabrics boast excellent strength and are commonly used in applications desiring a high-quality finish, such as aerospace components and luxury goods. 4. Leno weave: Leno weave is a distinctive pattern that involves twisting adjacent warp yarns around each weft yarn. This creates a stable and open structure with good strength and stability. Leno weave fabrics find common use in high strength applications where breathability and lightness are crucial, such as filtration systems and composites. These various fiberglass fabric weaves offer different levels of strength, flexibility, and durability, enabling manufacturers to select the most suitable weave for their specific high strength applications.

- Q: Can fiberglass fabric be used for heat-resistant aprons?

- Yes, fiberglass fabric can be used for heat-resistant aprons.

- Q: What is the dimensional stability of fiberglass fabric?

- Fiberglass fabric possesses remarkable dimensional stability, which is characterized by its capacity to sustain its shape and size without substantial stretching, shrinking, or warping in diverse circumstances. This outstanding dimensional stability is primarily attributed to the composition of fine glass fibers that are interlaced to create a taut and uniform structure. The glass fibers employed in fiberglass fabric demonstrate a high tensile strength, rendering them resistant to elongation or stretching. Consequently, the fabric remains true to its original dimensions even when subjected to mechanical stress or tension. Moreover, the glass fibers exhibit a low coefficient of thermal expansion, signifying minimal expansion or contraction in response to temperature fluctuations. This thermal stability greatly contributes to the fabric's ability to uphold its shape and size across a wide range of temperatures. Additionally, fiberglass fabric exhibits exceptional resistance to moisture absorption and chemical degradation. Unlike many other fabrics, fiberglass fabric repels water, thereby preventing significant absorption and subsequent dimensional alterations caused by moisture. Furthermore, the chemically inert nature of the glass fibers ensures resistance to most chemicals, safeguarding the fabric against chemical degradation that may compromise its dimensional stability. In conclusion, fiberglass fabric possesses excellent dimensional stability, making it a preferred choice in numerous industries such as aerospace, automotive, construction, and marine. Its capacity to maintain its shape, size, and structural integrity under diverse conditions renders it suitable for applications that demand consistent and dependable performance.

- Q: Can fiberglass fabric be used for reinforcement in water purification tanks?

- Indeed, fiberglass fabric proves to be a valuable asset when it comes to reinforcing water purification tanks. Renowned for its remarkable strength-to-weight ratio and long-lasting nature, fiberglass fabric stands as an ideal choice for fortifying tanks that endure perpetual water exposure. By bolstering the tank's structure, it effectively safeguards against deformation or collapse caused by the water's weight or external pressures. Moreover, fiberglass fabric's resistance to corrosion and chemicals guarantees its integrity, preventing any potential water contamination throughout the purification procedure.

- Q: Can fiberglass fabric be used for insulation in cold storage facilities?

- Yes, fiberglass fabric can be used for insulation in cold storage facilities. Fiberglass fabric is known for its excellent thermal insulation properties, making it an ideal choice for insulating cold storage facilities. It is highly effective in preventing heat transfer, thus maintaining the desired temperature inside the facility. Additionally, fiberglass fabric is resistant to moisture, mold, and mildew, which are common challenges in cold storage environments. This makes it a durable and long-lasting option for insulation. Moreover, fiberglass fabric is easy to install and can be customized to fit various shapes and sizes, ensuring proper coverage and insulation throughout the facility.

- Q: What are the different weights per square meter available for fiberglass fabric?

- Various applications and requirements can be accommodated by fiberglass fabric, which is available in a range of weights per square meter. Fiberglass fabric can be found in common weights such as 200g/m2, 300g/m2, 450g/m2, 600g/m2, and 900g/m2. These weights determine the fabric's thickness, strength, and durability. For instance, lighter weight fabrics like 200g/m2 are suitable for surfboard construction, whereas heavier weights like 900g/m2 are commonly used for industrial purposes such as reinforcing concrete structures or building boats. The choice of weight per square meter depends on the specific needs and intended use of the fiberglass fabric.

- Q: Is fiberglass fabric suitable for use in architectural applications?

- Yes, fiberglass fabric is suitable for use in architectural applications. Fiberglass is a versatile material that offers numerous benefits for architectural purposes. Its high tensile strength and durability make it suitable for use in applications such as reinforcing concrete structures, creating lightweight panels and cladding systems, and providing insulation. Fiberglass fabric can be molded into various shapes and sizes, allowing architects and designers to create unique and creative structures. It is also resistant to corrosion, chemicals, and moisture, making it suitable for both interior and exterior applications. Furthermore, fiberglass fabric is fire-resistant and has excellent thermal insulation properties. This makes it an ideal choice for architectural applications where fire safety and energy efficiency are important considerations. Additionally, fiberglass fabric is lightweight, which makes it easier to handle and install compared to other materials such as steel or concrete. Its flexible nature allows it to be easily draped or wrapped around complex architectural features. Moreover, fiberglass fabric is available in a wide range of colors and finishes, allowing architects to achieve the desired aesthetic appearance for their projects. However, it is important to note that fiberglass fabric may require proper maintenance and periodic inspections to ensure its long-term performance. Additionally, it is essential to follow proper installation techniques and guidelines provided by manufacturers to ensure its suitability and effectiveness in architectural applications. In conclusion, fiberglass fabric is a suitable material for use in architectural applications due to its strength, durability, versatility, fire resistance, thermal insulation properties, and aesthetic options. However, it is crucial to consider specific project requirements and consult with experts to determine the most appropriate use of fiberglass fabric in each architectural application.

- Q: Does fiberglass fabric have any health hazards?

- When used correctly, fiberglass fabric does not present significant health risks. However, it is crucial to exercise caution and take specific measures to reduce potential dangers when working with fiberglass fabric. The primary issue with fiberglass fabric lies in its ability to emit fine fibers or dust particles into the atmosphere, which can be harmful if inhaled. These fibers can cause irritation to the skin, eyes, and respiratory system, resulting in temporary symptoms like itching, redness, coughing, or breathing difficulties. Prolonged exposure to fiberglass fibers can also lead to more severe health problems, including lung scarring (fibrosis) or cancer. To prevent exposure and minimize health risks, it is advisable to consistently wear personal protective equipment (PPE) while handling fiberglass fabric. This includes donning gloves, long-sleeved clothing, safety glasses, and a dust mask or respirator. Furthermore, working in a well-ventilated area or utilizing local exhaust ventilation systems can effectively decrease the concentration of airborne fibers. It is important to note that fiberglass fabric itself is not toxic, as it consists of bonded glass fibers and resin. The potential health risks arise from the release of these fibers into the air, primarily during activities such as cutting, sanding, or other processes that generate dust. Overall, by adhering to proper safety protocols, fiberglass fabric can be used safely without significant health hazards. Nevertheless, it is imperative to take precautions to minimize exposure to airborne fibers and protect oneself when working with this material.

- Q: Is fiberglass fabric resistant to tears and punctures?

- Yes, fiberglass fabric is known for its high resistance to tears and punctures. It is a durable material that can withstand significant force and pressure without easily tearing or puncturing.

- Q: Can fiberglass fabrics be used for outdoor applications?

- Absolutely! Outdoor applications are perfect for fiberglass fabrics. The durability and ability to withstand harsh weather conditions are what make fiberglass an ideal material for outdoor use. It is commonly seen in outdoor furniture, awnings, canopies, and covers. Moreover, fiberglass fabrics are highly resistant to UV rays, moisture, and mildew, ensuring that they retain their strength and appearance when exposed to the elements. Additionally, their lightweight and flexible nature make fiberglass fabrics a breeze to install and work with for any outdoor project.

Send your message to us

Silicone Rubber Coated Fiberglass Fabric for Thermal Insulation at High Temperatures

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords