Shaft Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

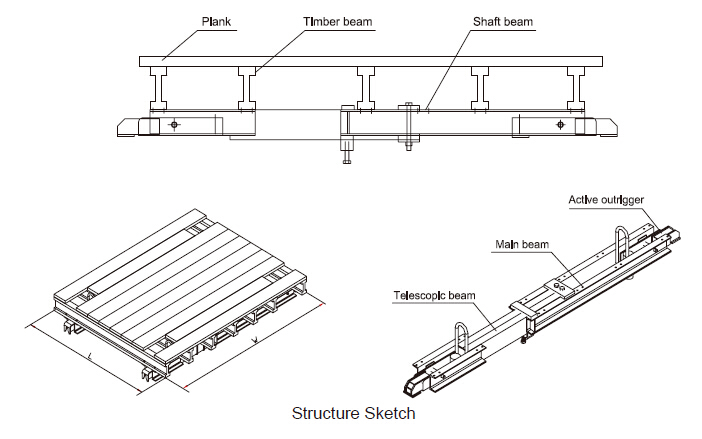

Shaft Platform

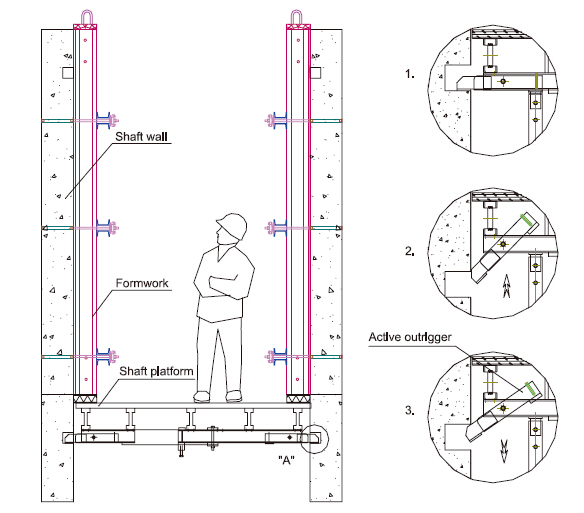

As operating platform, the shaft platform is mainly used in the concrete pouring of elevator shaft,

equipment shaft, stair shaft of high-rise building and so on.

Characteristics:

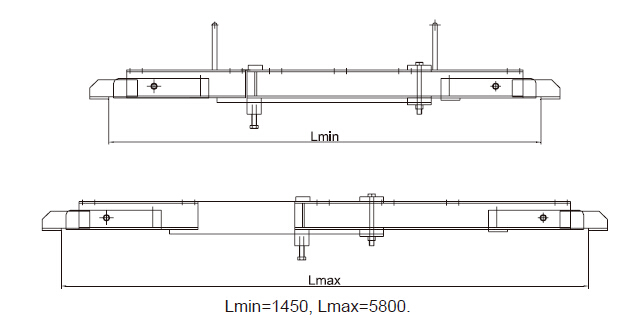

◆ The length of shaft beam is adjustable.

◆ Flexible structure makes lifting easier.

- Q: What are some of the components of the combined steel template, what role?

- 3, the connector has a U shaped card L - shaped bolt, hook head bolts, fastening bolts, pull bolt, dish shaped fasteners, 3 - shaped fasteners, such as plate type pull rod.4, support tools supporting steel pile, steel column, steel column hoop, hoop steel, steel beam, steel pipe clamp fixture pillar (supporting), steel brace. Planar adjustable steel frame, wood, etc..5, the isolation agent commonly used waste oil and diesel oil (1:1 ~ 4) and silicone co hydrolysate and gasoline (1:10), etc.

- Q: How does steel formwork handle concrete finishing and curing agents?

- Steel formwork is highly resistant to the chemical agents commonly used in concrete finishing and curing processes. Its durable and non-absorbent surface prevents the concrete from adhering to the formwork, allowing for easy release and smooth finishing of the concrete surface. Additionally, the steel formwork's rigidity and stability ensure that the concrete maintains its desired shape and prevents any deformation during the curing process.

- Q: How does steel formwork affect the overall sustainability of a construction project?

- Steel formwork can greatly enhance the overall sustainability of a construction project. Due to its durability and longevity, steel formwork can be reused multiple times, reducing the need for frequent replacement and minimizing waste generation. Additionally, its strength allows for the construction of more robust and resilient structures, reducing the likelihood of future repairs or replacements. Moreover, steel formwork enables efficient and precise construction, resulting in lower material and labor requirements, reducing energy consumption and environmental impact. Thus, by promoting resource efficiency, reducing waste, and improving structural performance, steel formwork positively contributes to the sustainability of a construction project.

- Q: How does steel formwork handle concrete temperature differentials?

- Steel formwork is known for its strength and durability, which allows it to effectively handle concrete temperature differentials. The thermal conductivity of steel helps in evenly distributing the heat or cold generated by the concrete during the curing process. This prevents the formation of cracks or other structural issues that can occur due to uneven temperature distribution. Additionally, steel formwork provides stability and rigidity, ensuring that the concrete maintains its desired shape and strength even when exposed to varying temperatures.

- Q: What are the considerations when designing steel formwork for water tanks?

- When designing steel formwork for water tanks, several considerations must be taken into account. Firstly, the formwork needs to be structurally strong and capable of withstanding the weight and pressure of the water it will contain. This involves carefully selecting the thickness and quality of the steel, as well as ensuring proper reinforcement and bracing. Additionally, the formwork should be designed to allow for easy assembly, disassembly, and reusability. This is important as water tanks may need to be relocated or replaced in the future. The formwork should have a modular design and be easily adjustable to accommodate different tank sizes and shapes. Furthermore, attention should be given to the waterproofing and leakage prevention of the formwork. This can be achieved through the use of appropriate sealing materials and techniques, ensuring that the tank remains watertight. Finally, considerations should be made for the ease of maintenance and inspection. The formwork should allow for easy access to the interior of the tank for cleaning and repair purposes. Properly designed access points, such as manholes, should be incorporated into the formwork design. Overall, designing steel formwork for water tanks requires careful consideration of structural integrity, ease of assembly and maintenance, waterproofing, and adaptability to various tank sizes and shapes.

- Q: Can steel formwork be used for both small-scale and large-scale projects?

- Steel formwork is suitable for both small-scale and large-scale projects. It is highly adaptable and can easily be tailored to fit different project sizes and requirements. With its exceptional strength and durability, steel formwork is ideal for large-scale projects involving heavy concrete structures. Moreover, it can be reused multiple times, making it a cost-effective option for projects of any size. Its inflexible structure guarantees precise concrete placement, which is crucial for achieving top-notch results in any project. Therefore, whether it's a small-scale residential construction or a large-scale commercial development, steel formwork is a dependable choice for the successful implementation of concrete works.

- Q: How does steel formwork impact the overall project budgeting?

- Steel formwork can have a significant impact on the overall project budgeting. While the initial cost of steel formwork may be higher compared to other types of formwork, such as wood or plastic, it offers several advantages that can help offset the initial investment. Firstly, steel formwork is known for its durability and longevity. Unlike wood or plastic formwork, steel formwork can be reused multiple times without losing its structural integrity. This reusability factor reduces the need for frequent replacement or repair, thereby saving costs in the long run. Moreover, steel formwork provides a high-quality finish to concrete structures. The smooth and even finish achieved with steel formwork reduces the need for additional surface treatments or finishing work, resulting in cost savings. Additionally, steel formwork offers enhanced strength and stability, allowing for larger and more complex structures to be built. This can eliminate the need for additional support systems or reinforcements, which can be expensive and time-consuming. Furthermore, steel formwork is easy to assemble and dismantle, resulting in faster construction times. The quick turnaround time reduces labor costs and allows for earlier project completion, which can be particularly beneficial in time-sensitive projects. Lastly, steel formwork is resistant to weather conditions, such as moisture or extreme temperatures, which can negatively impact the formwork's effectiveness and lifespan. This resistance reduces the risk of formwork damage and replacement costs, thereby contributing to cost savings. Overall, while steel formwork may have a higher upfront cost, its durability, reusability, high-quality finish, strength, ease of use, and resistance to weather conditions can all contribute to cost savings in terms of reduced labor, material, and maintenance expenses. Therefore, steel formwork can have a positive impact on the overall project budgeting.

- Q: What are the common design considerations for steel formwork in earthquake-prone areas?

- In earthquake-prone areas, the design considerations for steel formwork are crucial to ensure the safety and stability of structures during seismic events. Some common design considerations for steel formwork in earthquake-prone areas include: 1. Material Strength: The steel used in formwork should have high tensile strength to withstand the lateral forces generated during an earthquake. High-strength steel, such as Grade 60 or Grade 80, is commonly used in earthquake-resistant formwork designs. 2. Reinforcement: The formwork should be adequately reinforced to enhance its rigidity and resistance to seismic forces. Additional reinforcement can be provided by adding steel braces, cross-bracing, or diagonal members to increase the structural integrity of the formwork system. 3. Connection Details: The connection details between different formwork elements should be designed to withstand the dynamic forces induced by earthquakes. Welded or bolted connections are commonly used, ensuring that they have adequate strength and ductility to resist seismic loads. 4. Stiffness and Flexibility: The formwork system should exhibit an appropriate balance between stiffness and flexibility. It should be rigid enough to resist lateral forces during an earthquake but also flexible enough to absorb and dissipate seismic energy without collapsing. 5. Anchorage Systems: Anchorage systems are crucial in securing the formwork to the foundation or supporting structure. These systems should be designed to resist the uplift and lateral forces generated during an earthquake and prevent the formwork from overturning or sliding. 6. Diaphragm Action: To enhance the overall structural performance, the formwork system should be designed to provide diaphragm action. This means that the formwork acts as a continuous and rigid panel transferring forces across its surface, thereby reducing localized stresses and improving the overall stability of the structure during an earthquake. 7. Formwork Compatibility: The steel formwork should be compatible with other structural elements, such as concrete columns, beams, and slabs. It is essential to ensure that the formwork system can adequately transfer the loads from the concrete to the supporting structure without compromising its stability or integrity during seismic events. 8. Construction Practices: In addition to design considerations, proper construction practices play a vital role in ensuring the effectiveness of steel formwork in earthquake-prone areas. Adequate bracing and temporary supports should be used during formwork assembly to maintain stability and prevent collapse before the concrete is poured and hardened. By considering these design considerations, engineers and designers can develop robust steel formwork systems that can withstand the forces exerted by earthquakes and ensure the safety of structures in seismic regions.

- Q: How does steel formwork accommodate openings and penetrations in the concrete?

- Steel formwork can accommodate openings and penetrations in the concrete by incorporating removable panels or cutouts in the formwork design. These panels can be easily removed or adjusted to create spaces for windows, doors, ducts, pipes, or any other required penetrations in the concrete structure. This flexibility allows for precise and efficient construction, ensuring that the concrete is poured accurately around the openings and penetrations, resulting in a well-structured and functional building.

- Q: What are the common problems encountered with steel formwork?

- Construction projects can encounter several common problems with steel formwork. One primary issue involves corrosion. When exposed to moisture or harsh environments, steel formwork is susceptible to rust and deterioration. This can compromise the structure's integrity, weakening it and creating potential safety hazards. Another problem arises from the heavy weight of steel formwork, making its handling and transportation difficult. This challenge is particularly evident on-site, especially in tight spaces or high-rise buildings. Moreover, the weight of the steel formwork increases labor and equipment costs required for installation. Additionally, regular maintenance is necessary to prevent damage and ensure the longevity of steel formwork. This maintenance involves cleaning, repairing any corrosion or dents, and applying protective coatings to prevent further deterioration. However, this maintenance can be both time-consuming and costly, contributing to the overall project expenses. Furthermore, steel formwork may not be suitable for certain construction applications. It lacks the easy customization and adjustability found in other formwork materials like timber or plastic. Consequently, its flexibility in accommodating unique shapes or designs is limited. Lastly, steel formwork generally incurs higher costs compared to other formwork materials. This financial aspect can impact the project budget, particularly for smaller or budget-constrained construction projects. To ensure a successful construction project, it is crucial to acknowledge these common problems and take necessary precautions. This involves regular maintenance, proper handling, and considering alternative formwork materials when appropriate. By addressing these issues, the durability and strength offered by steel formwork can be maximized.

Send your message to us

Shaft Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords