Shaft Platform for Formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

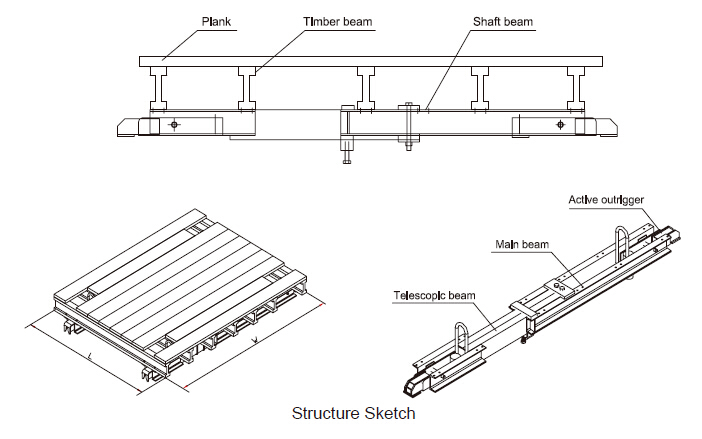

Shaft Platform

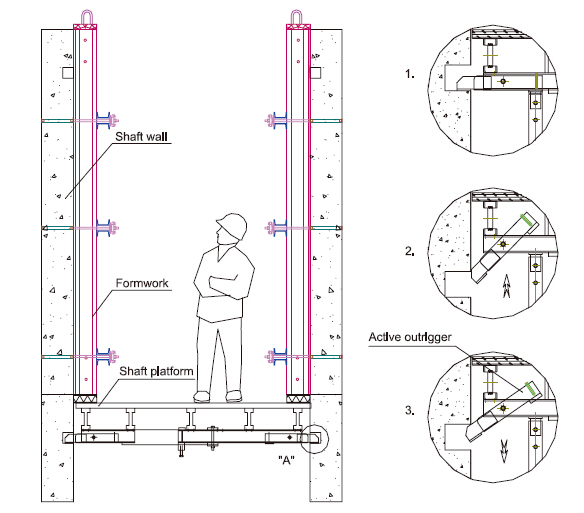

As operating platform, the shaft platform is mainly used in the concrete pouring of elevator shaft,

equipment shaft, stair shaft of high-rise building and so on.

Characteristics:

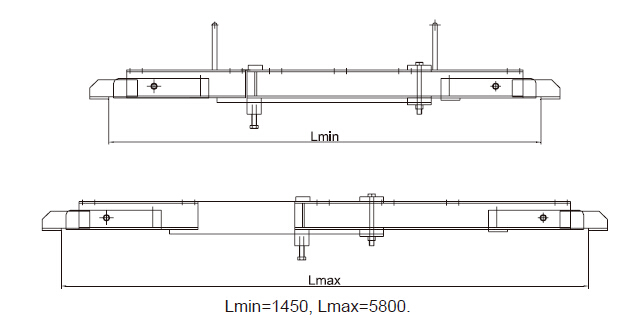

◆ The length of shaft beam is adjustable.

◆ Flexible structure makes lifting easier.

- Q: Can steel formwork be used for decorative concrete finishes?

- Yes, steel formwork can be used for decorative concrete finishes. It provides sturdy support and precise shaping, allowing for intricate designs and smooth finishes in decorative concrete applications.

- Q: Does steel formwork require any special equipment for installation?

- Indeed, special equipment is needed for the installation of steel formwork. To install it, one must assemble the steel panels into the desired shape and fasten them together. This typically entails utilizing specific tools like spanners, hammers, or hydraulic jacks to guarantee proper alignment and tightness of the formwork. Furthermore, robust lifting equipment such as cranes or forklifts might be required to safely transport and position the steel formwork panels. By employing specialized equipment, one can ensure the installation is conducted with precision and effectiveness, ultimately yielding a durable and expertly constructed formwork system.

- Q: Is steel formwork resistant to corrosion?

- Yes, steel formwork is resistant to corrosion.

- Q: Can steel formwork be used for precast concrete beams?

- Indeed, precast concrete beams can utilize steel formwork. Demonstrating durability and rigidity, steel formwork effectively endures the weight and pressure exerted by the concrete during casting. It furnishes a seamless and uniform surface to facilitate pouring the concrete, guaranteeing the anticipated shape and dimensions of the beam. Moreover, steel formwork enables effortless demolding and reusability, rendering it a financially prudent option for manufacturing precast concrete beams.

- Q: How does steel formwork affect the overall aesthetics of the structure?

- The overall appearance of a structure can be greatly influenced by the use of steel formwork. Its smooth and sleek surface finish gives a clean and contemporary look, which is highly desired in modern architectural designs. The precision and accuracy of steel formwork also allow for the creation of intricate details and complex shapes, enhancing the visual appeal of the structure. In addition, steel formwork allows for the creation of sharp edges and precise lines, resulting in a more refined and sophisticated appearance. This is especially advantageous for structures with exposed concrete surfaces, as the use of steel formwork eliminates the need for additional surface treatments or finishing materials. Furthermore, steel formwork provides versatility in terms of creating different textures and patterns on the concrete surface. Architects and designers can enhance the visual impact of the structure and create unique aesthetic effects by utilizing various surface treatments or coatings, such as acid etching or powder coating. Moreover, steel formwork is known for its durability and structural integrity, ensuring that the aesthetics of the structure remain intact over time. Unlike other types of formwork, steel formwork does not warp or deform, providing a consistent and uniform appearance throughout the construction process and beyond. In conclusion, steel formwork has a positive impact on the overall aesthetics of a structure by providing a sleek and modern finish, allowing for intricate detailing and complex shapes, creating sharp edges and precise lines, offering versatility in texture and pattern, and ensuring long-lasting durability.

- Q: How does steel formwork affect the overall vibration resistance of the structure?

- A structure can greatly improve its vibration resistance through the utilization of steel formwork. Steel, as a formwork material, offers several advantages that contribute to enhanced structural stability and reduced vibrations. To begin with, steel formwork is renowned for its exceptional strength and rigidity. It provides a sturdy framework that can withstand the dynamic forces and loads experienced by a structure throughout its lifespan. This increased strength aids in the minimization of potential vibrations caused by external factors such as wind, earthquakes, or nearby heavy machinery operations. Additionally, steel formwork enables a precise and accurate construction process, ensuring a tight fit and proper alignment of structural elements. This precise assembly reduces the presence of any gaps or unevenness, which can amplify vibrations. By minimizing these irregularities, the overall vibration resistance of the structure is improved. Moreover, steel formwork exhibits excellent dimensional stability, meaning it remains unchanged in size, shape, or form under varying environmental conditions. This stability guarantees that the structure maintains its integrity and avoids significant deformations that could lead to increased vibrations. Furthermore, steel formwork possesses remarkable resistance to corrosion and deterioration, ensuring its long-term durability. This resistance prevents any weakening of the structure over time, which is crucial for maintaining its vibration resistance. Furthermore, steel formwork offers a higher load-carrying capacity compared to other formwork materials. This increased capability allows for the construction of more robust and resilient structures that can withstand higher dynamic loads without experiencing excessive vibrations. In conclusion, the utilization of steel formwork greatly enhances the overall vibration resistance of a structure by providing strength, rigidity, precision, dimensional stability, corrosion resistance, and increased load-carrying capacity. By incorporating these characteristics, steel formwork helps to minimize vibrations and ensures the structural integrity and safety of the building.

- Q: How does steel formwork handle reinforcement placement?

- Steel formwork handles reinforcement placement by providing a rigid and sturdy structure that holds the reinforcement bars in place during the concrete pouring process. The formwork is designed with pre-determined spaces and supports to accurately position the reinforcement bars in the desired locations as per the structural drawings. This ensures that the reinforcement is properly aligned and secured before the concrete is poured, resulting in a strong and durable structure.

- Q: What are the common cost implications of using steel formwork in a construction project?

- The utilization of steel formwork in a construction project can result in several cost implications, both positive and negative. One of the common cost implications of employing steel formwork is the higher initial investment required in comparison to other formwork materials like timber or aluminum. Steel formwork typically entails a greater upfront purchase or rental expense, which can elevate the initial costs of the project. Nonetheless, it is crucial to take into account the long-term advantages of steel formwork, since its durability and ability to be reused can offset these initial expenditures. Another cost implication of using steel formwork is the reduction in labor and material costs. Steel formwork is renowned for its robustness and capacity to support heavy loads, permitting larger spans and heights to be accomplished with fewer supports. Consequently, less labor and material are necessary for support structures, resulting in potential cost savings. Moreover, the utilization of steel formwork can facilitate increased construction speed and efficiency, which can translate into cost savings. Steel formwork systems are designed for straightforward assembly and disassembly, enabling faster construction cycles. This can aid in diminishing labor costs and overall project duration, thereby minimizing the impact of inflation and other potential cost escalations. Furthermore, the durability and reusability of steel formwork can contribute to long-term cost savings. Unlike timber or plywood formwork, steel formwork can endure multiple uses without significant deterioration. This extends its lifespan and diminishes the need for frequent replacements or repairs, leading to financial savings on material costs in the long run. However, it is important to acknowledge that steel formwork may necessitate additional expenses for transportation and storage. Steel formwork is heavier and bulkier than alternative materials, which can augment transportation costs. Additionally, proper storage and maintenance are vital to ensure the longevity of steel formwork, which may entail supplementary expenses for cleaning, rust prevention, and storage facilities. To conclude, although there may be higher initial costs involved in employing steel formwork in a construction project, the long-term benefits of durability, reuse, reduced labor, and increased construction speed can outweigh these expenses. A thorough evaluation of the specific project requirements, budget, and timeline is necessary to ascertain whether the cost implications of using steel formwork are advantageous for a particular construction project.

- Q: Are there any safety precautions to consider when using steel formwork?

- Yes, there are several safety precautions to consider when using steel formwork. 1. Proper training: It is essential that all workers using steel formwork receive proper training on the correct handling and assembly procedures. This includes understanding the safe load capacity, proper installation techniques, and dismantling processes. 2. Inspection and maintenance: Regular inspection and maintenance of the steel formwork is crucial to ensure its structural integrity. Any signs of damage, such as cracks, bent parts, or loose connections, should be immediately addressed and repaired. 3. Personal protective equipment (PPE): All workers involved in the steel formwork operations should wear appropriate PPE, including helmets, safety goggles, gloves, and steel-toe boots. This will protect them from potential hazards, such as falling objects, sharp edges, or accidental contact with the formwork. 4. Secure and stable platform: It is important to provide a secure and stable platform for workers to access and work on the steel formwork. This may involve using scaffolding, ladders, or elevated work platforms that are properly secured and meet safety standards. 5. Fall protection: Implementing fall protection measures is crucial when working at heights. This may include installing guardrails, safety nets, or personal fall arrest systems to prevent falls and protect workers from serious injuries. 6. Material handling: Proper lifting techniques should be followed when handling steel formwork components to prevent strain or muscle injuries. The use of mechanical lifting equipment, such as cranes or forklifts, can also help minimize the risk of accidents. 7. Communication and coordination: Clear communication and coordination among workers involved in the steel formwork operations is vital to ensure everyone's safety. This includes establishing a clear chain of command, using hand signals or radios for communication, and conducting regular safety meetings to address any concerns or issues. By following these safety precautions, the risk of accidents, injuries, and damage can be significantly reduced when using steel formwork.

- Q: What are the different types of accessories used in steel formwork installation?

- There are several types of accessories used in steel formwork installation, including form ties, wedges, clamps, spreaders, and braces. These accessories help secure and stabilize the formwork system, ensuring that the concrete is poured and set properly.

Send your message to us

Shaft Platform for Formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords