Shaft platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

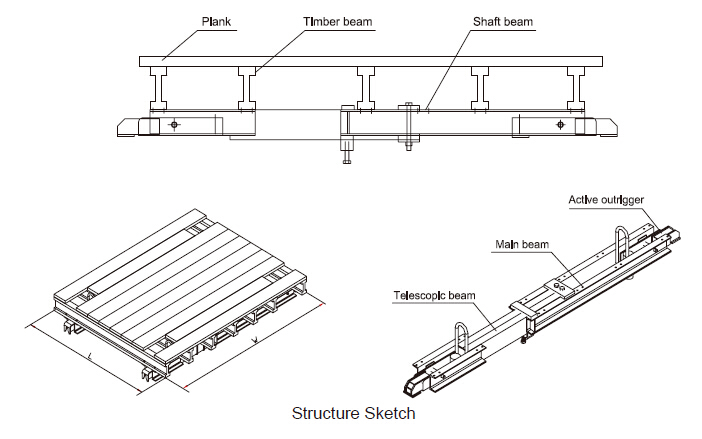

Shaft Platform

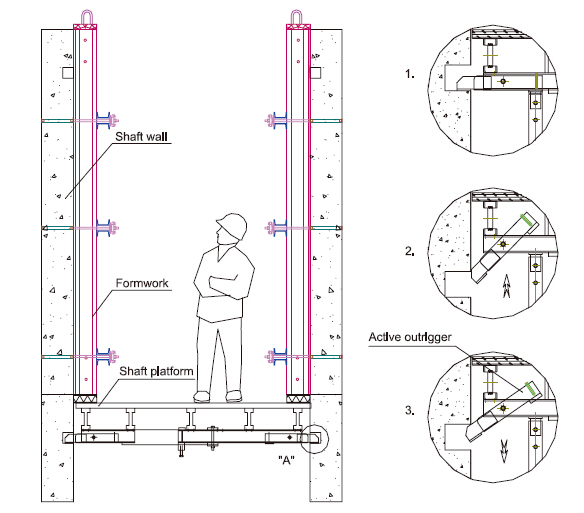

As operating platform, the shaft platform is mainly used in the concrete pouring of elevator shaft,

equipment shaft, stair shaft of high-rise building and so on.

Characteristics:

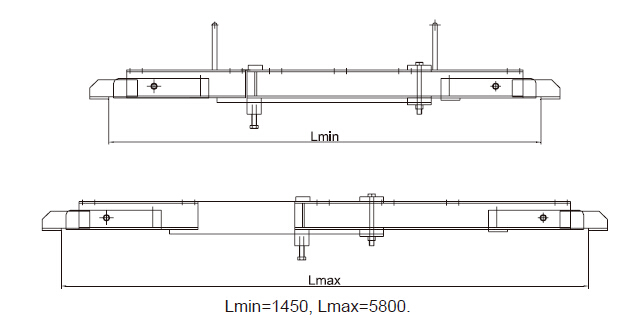

◆ The length of shaft beam is adjustable.

◆ Flexible structure makes lifting easier.

- Q:How does steel formwork contribute to the sustainability of a construction project?

- Steel formwork contributes to the sustainability of a construction project in several ways. Firstly, steel formwork is durable and long-lasting, reducing the need for frequent replacements and minimizing waste generation. Additionally, steel is a recyclable material, meaning that at the end of its life cycle, it can be recycled and used again in other construction projects, reducing the demand for new raw materials. Furthermore, steel formwork allows for efficient and precise construction, minimizing material wastage and reducing energy consumption. Overall, the use of steel formwork promotes sustainability by minimizing waste generation, conserving resources, and enhancing construction efficiency.

- Q:How is steel formwork manufactured?

- Steel formwork is manufactured through a series of processes that involve shaping and assembling steel components into the desired formwork structure. The manufacturing process typically begins with the selection of high-quality steel, which is then cut and shaped into various components such as panels, beams, and connectors. One of the key steps in steel formwork manufacturing is the fabrication of panels. This involves cutting steel sheets to the required size and shape using specialized cutting tools such as shears or plasma cutters. These panels are then further processed to create the necessary openings or holes for connectors and accessories. Once the panels are ready, they are assembled together using connectors and fasteners. This assembly process may involve welding, bolting, or riveting, depending on the specific design and requirements of the formwork. The connections are carefully made to ensure the strength and stability of the steel formwork structure. In addition to panels, steel formwork also includes beams and other support components. These are fabricated separately and then integrated into the formwork system during the assembly process. Beams are typically designed to bear heavy loads and provide additional stability to the formwork structure. After the assembly is complete, the steel formwork undergoes a quality inspection to ensure that it meets the required standards and specifications. This inspection involves checking for any defects, such as cracks or deformations, as well as verifying the accuracy of dimensions and connections. Once the steel formwork passes the quality inspection, it is usually surface-treated to enhance its durability and resistance to corrosion. This treatment can involve techniques such as galvanizing or painting, which create a protective layer on the steel surface. Overall, the manufacturing process of steel formwork involves precision cutting, shaping, and assembling of steel components to create a robust and reliable system for concrete construction. The use of high-quality materials and careful attention to detail ensures that steel formwork meets the demands of various construction projects, providing a strong and reusable solution for concrete formwork requirements.

- Q:What is the difference between the steel template and the assembled steel template?

- Stereotypes templates such as 1200*2001500*300 and so on and the combination of steel template is the use of these provisions of the steel template to be spliced into the target combination template.

- Q:How does steel formwork handle different concrete durability requirements?

- Steel formwork proves to be a flexible and long-lasting option capable of effectively managing diverse concrete durability demands. The concrete's pouring forces and pressures are well withstood thanks to the strength and rigidity of steel. The adaptability of steel formwork is highly remarkable as it can be tailored to fulfill specific durability criteria. Consequently, formwork systems that endure harsh environmental conditions like extreme temperatures, moisture, and chemical exposure can be created. Furthermore, steel formwork can be designed to accommodate different load-bearing requirements, ensuring the stability and security of the structure throughout the concrete casting process and beyond. Furthermore, steel formwork guarantees excellent dimensional stability, a key aspect in achieving accurate and precise concrete finishes. This becomes particularly crucial when constructing structures that demand a high level of aesthetic appeal or intricate architectural designs. Additionally, the reusability of steel formwork sets it apart. Unlike other formwork types, steel can be utilized multiple times, effectively minimizing waste and reducing overall construction costs. Consequently, it emerges as a cost-effective solution for projects with varying concrete durability requirements as the formwork can be easily adjusted and reused for different purposes. In conclusion, steel formwork stands as a dependable and adaptable solution that effectively handles diverse concrete durability requirements. Its strength, customizability, dimensional stability, and reusability render it an ideal choice for a wide range of construction projects, ensuring that the desired durability standards of concrete structures are met.

- Q:Can steel formwork be used for staircase construction?

- Yes, steel formwork can be used for staircase construction. Steel formwork is a versatile and durable material that is commonly used in construction projects, including staircase construction. It provides a strong and stable structure for pouring concrete and ensures precise and accurate shaping of the staircase. Additionally, steel formwork is reusable, making it a cost-effective choice for repetitive construction processes like staircase construction. It also offers flexibility in design, allowing for the creation of various staircase shapes and sizes. Overall, steel formwork is a suitable choice for staircase construction due to its strength, durability, reusability, and design flexibility.

- Q:What are the different types of steel formwork supports?

- There are several different types of steel formwork supports that are commonly used in construction projects. Some of the main types include: 1. Adjustable Steel Props: These are vertical supports that can be adjusted to desired heights. They are made of steel tubes with an adjustable inner and outer tube, allowing for easy height adjustment. Adjustable steel props are commonly used to support horizontal formwork or scaffolding systems. 2. Soldier Formwork System: This type of steel formwork support consists of vertical steel members known as soldiers that are spaced at regular intervals along the formwork. Soldiers are designed to resist the lateral pressure of wet concrete and provide support to the formwork panels. 3. Trench Struts: Trench struts are used to support and stabilize formwork in trenches or excavations. They consist of steel tubes with adjustable length and are typically used in conjunction with steel walers or beams to create a sturdy framework for the formwork. 4. H-Frame Systems: H-frame systems are commonly used for vertical formwork supports. They consist of steel frames in the shape of an "H" that are connected together to create a stable structure. H-frame systems are often used for supporting vertical formwork panels or as a framework for climbing formwork systems. 5. Steel Waler: A steel waler is a horizontal member used to support the formwork panels. It is typically made of steel channels or beams and is used in conjunction with vertical supports like adjustable steel props or trench struts. These are just a few examples of the different types of steel formwork supports that are commonly used in construction. The choice of support system depends on the specific requirements of the project, such as the formwork design, load capacity, and desired adjustability.

- Q:How does steel formwork handle concrete curing?

- Steel formwork is an ideal choice for concrete curing due to its durability and strength. The steel formwork provides a rigid framework, ensuring that the concrete maintains its desired shape and structure during the curing process. Additionally, steel formwork allows for easy demolding once the concrete has cured, saving time and effort.

- Q:How does steel formwork contribute to the overall energy efficiency of the building?

- Steel formwork contributes to the overall energy efficiency of a building in several ways. Firstly, steel has excellent thermal conductivity, allowing it to absorb and dissipate heat effectively, which helps in maintaining a comfortable indoor temperature and reducing the reliance on heating and cooling systems. Additionally, steel formwork provides a strong and durable structure that minimizes air leakage and heat loss, improving the overall insulation of the building. Moreover, steel formwork is reusable and can be easily dismantled and repurposed, reducing the energy and resources required for manufacturing new formwork for future construction projects. Overall, steel formwork plays a crucial role in enhancing the energy efficiency of buildings, leading to reduced energy consumption and lower carbon emissions.

- Q:How does steel formwork affect the overall timeline of a construction project?

- Steel formwork can have a significant impact on the overall timeline of a construction project. One of the major advantages of using steel formwork is its durability and reusability. Unlike traditional timber formwork, steel formwork can be used multiple times, which reduces the time spent on constructing and dismantling formwork for each concrete pour. The strength and rigidity of steel formwork also allow for faster construction cycles. Since steel formwork can withstand higher concrete pressure, it enables faster pouring and setting of concrete, leading to shorter curing times. This, in turn, allows subsequent construction activities to commence earlier, ultimately accelerating the overall project timeline. Moreover, steel formwork is known for its precision and dimensional stability. It provides a smooth and accurate surface finish, eliminating the need for additional plastering or leveling work. This saves time and reduces the number of construction activities required, further enhancing the project timeline. Additionally, steel formwork is typically prefabricated, meaning it is manufactured off-site and delivered to the construction site ready for assembly. This significantly reduces on-site construction time, as the formwork can be quickly erected and adjusted to the desired shape and dimensions. This timely installation ensures that other trades can progress with their work without delays, ultimately speeding up the overall construction process. However, it is important to note that the initial setup time for steel formwork can be longer compared to other types of formwork, as it requires careful planning and coordination. The formwork design must be accurately calculated, and any modifications or adjustments may take additional time. Nevertheless, the time saved during subsequent concrete pours and other construction activities usually compensates for this initial setup period. In conclusion, steel formwork positively impacts the overall timeline of a construction project by reducing the time spent on constructing and dismantling formwork, enabling faster concrete pouring and curing, providing a precise and finished surface, and facilitating quick and efficient on-site assembly. Its durability and reusability contribute to a more efficient and timely construction process, resulting in a shorter overall project duration.

- Q:How does steel formwork affect the overall construction site aesthetics?

- The overall aesthetics of a construction site can be significantly impacted by the use of steel formwork. In contrast to traditional timber formwork, steel formwork offers a sleek and contemporary look. The smooth and pristine surfaces of steel formwork convey a sense of precision and professionalism to the construction site. Moreover, the utilization of steel formwork provides greater design flexibility. It can be effortlessly shaped and molded into intricate forms, resulting in visually appealing and one-of-a-kind structures. This flexibility empowers architects and designers to create innovative and captivating architectural elements that enhance the overall aesthetics of the construction site. Furthermore, steel formwork plays a role in maintaining the cleanliness of the construction site. Its durable and reusable nature minimizes waste generated during the construction process. This not only contributes to a cleaner and more organized site, but also reduces the environmental impact of the construction process. Additionally, steel formwork instills a sense of durability and strength to the construction site. Its sturdy nature ensures that the structures being constructed are solid and long-lasting. This further enhances the impression of quality and stability, ultimately improving the aesthetics of the construction site. In conclusion, the use of steel formwork has a positive impact on the overall aesthetics of a construction site. It provides a modern and sleek appearance, enables flexible and innovative designs, contributes to cleanliness, and enhances the sense of durability and strength.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Shaft platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords