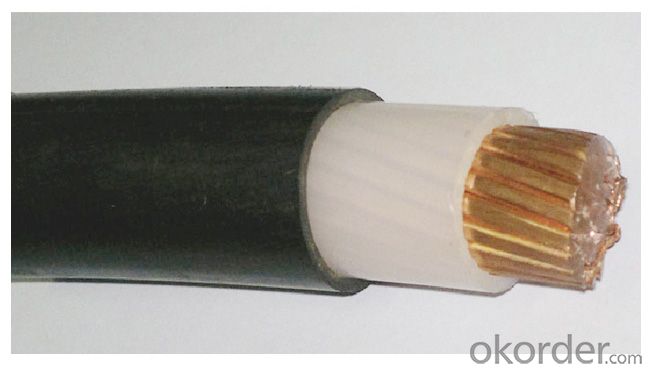

SDI CABLES XLPE 600/1000V Single Core Copper per AS/NZS 5000.1

OKorder Service Pledge

OKorder Financial Service

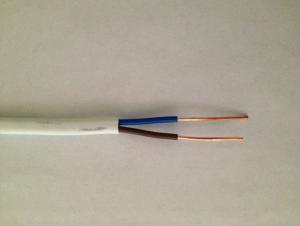

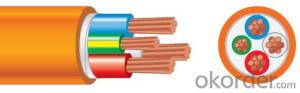

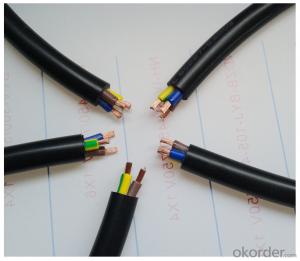

You Might Also Like

SDI cable for Australia market 600/1000V to AS/NZS 5000.1

Applications:

For mains, submains and subcircuits unenclosed, enclosed in conduit, buried direct or in underground ducts for buildings and industrial plants where not subject to mechanical damage. Suitable where space is at premium and/or where conditions of overload may occur. Suitable for glanding.

Rated voltage: 600/1000V

Conductor: Copper 16~630 mm2

Insulation: XLPE, X-90. Natural

sheath: PVC, 5V-90. Black

Environmental performance: Normal operating temp. 90℃

Standards compliance: AS/NZS 5000.1

OEM can be available

Remark: Flame retardant or fire resistance or Low Smoking and Halogen free or other property can be available

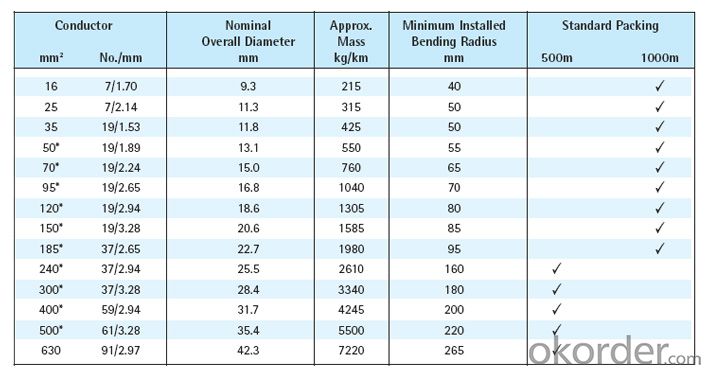

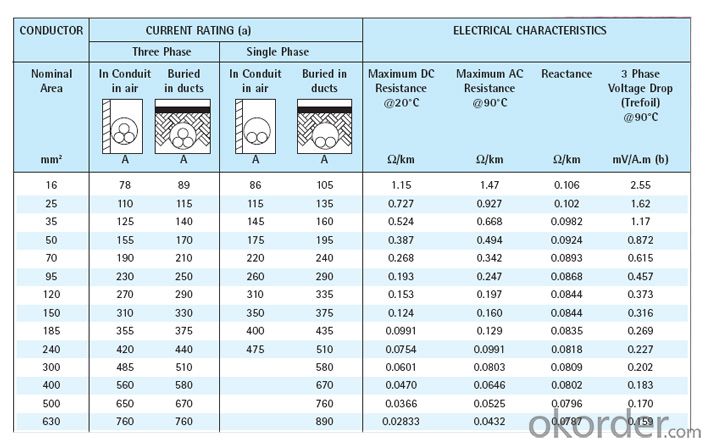

Parameter sheet

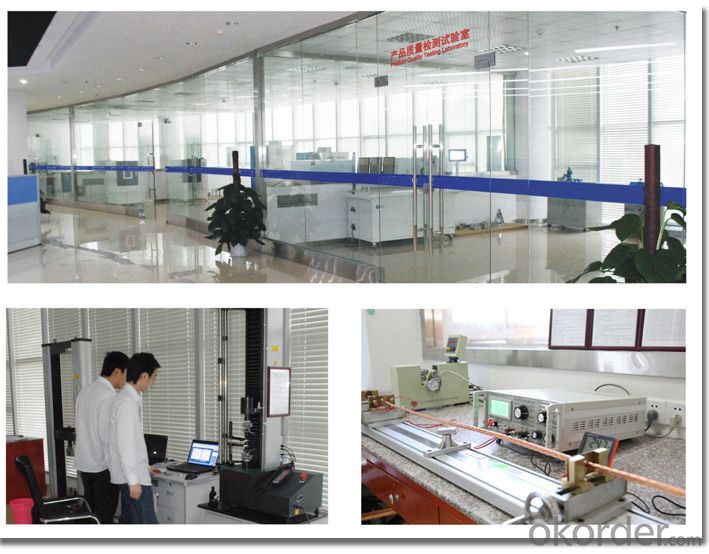

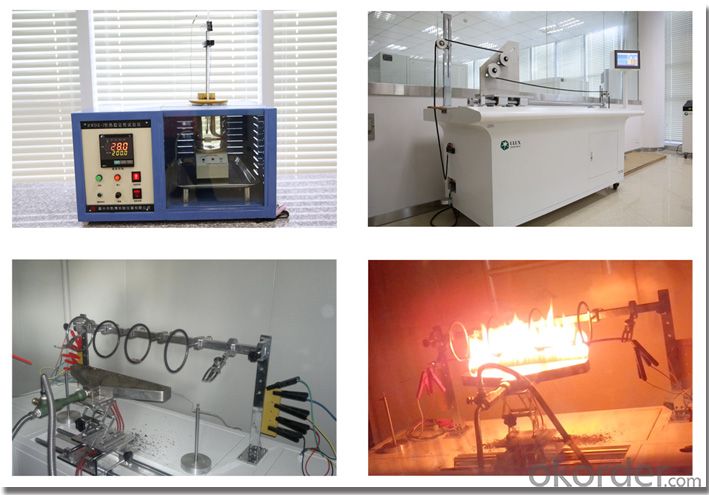

Main Quality Inspection Equipment

Sparker tester,Heating aging Chamber,High resistance machine, Oxygen index equipment, Partial discharge inspection instruments, Fireproof testing device,High-power voltage withstand tester,No-rotor Vulkameter,Pull tester,Analytical balance,Direct current bridge,Plastic tester,Projector, Punch machine,Cross-linked cutting machine,etc.

Company Overview

Certificates

- Q: All the DIY info shows how to change a light fixture. What do you do with the wiring if you want to remove a chandelier, but not replace it with another?I want to make sure the wires in the ceiling are not capable of starting a fire. This is in the first floor of a two-story.

- TURN CIRCUIT OFF.GET A LADDER,SCREW DRIVERS,WIRE NUTS,ELECTRICAL TAPE,COVER PLATE FOR THE HOLE OR YOU CANREFILL HOLE.UNSCREW CHANDELIER, USING SNIPS CUT WIRES,PUT WIRE NUTS OR EACH INDIVIDUAL WIRE,THEN TAPE EACH SEPERATE BUT TOGETHER SO IF NEEDED AGAIN.OR GO TO THE WALL SWITCH.UNSCREW PLATE,TAPE WIRES SEPERATE THEN BIND TOGETHER,IF YOU ARE GOING TO REPLACE CHANDELIER WITH ANOTHER LIGHT INSTALL LIGHT ON CHANDELIER END

- Q: I have received formal training on electrical wiring, but do not have the certifications to prove that I can do the wiring in a safe manner with the law in mind. I'm very conscious when it comes to working with the grids.

- You will have to pay an electrician to do the work and certify it. No electrician worth his salt will certify something that someone with no formal training has done.

- Q: Hi, I'm finishing part of my basement and will be running new wires and adding electrical outlets. I've some question about the electrical wiring code: I frame the wall with 2x4 with a few inches distance off the concrete wall. 1. When running wire from wall to ceiling joint, can I run the wire around the inner side of the top plate(between studs and concrete wall) instead of drilling hole on the top plate and running through the hole? I will staple the rest of the wire along the stud and joint too, 11/4 inch away to the rim.2. When drilling the hole in the stud for wiring, can I drill the hole closer to the concrete wall but the hole is less than 11/4 to the inner side of the stud? Is this against the code? I know I cann't nail from the inner side after framing:)3. It the 6 feet rule aplly also to basemnent as a recreation room, for all walls?4. Is wall switch-controlled lighting outlet means I have to install switch controlled receptacle or switch controlled light is enough? Thanks for your help!

- I may not be right, but I'll take a stab at this one. Let's run it down by the numbers. 1) No, you may not run the Romex through that gap, you have to drill a hole. 2) It's accepted practice to put the hole a little on the deep side of the stud, but you still use hammer on steel wire protector covers before you hang your drywall. 3) The 6 foot rule applies to everything I've ever seen. 4) If you have an overhead light fixture, you don't need a switched outlet. Switched outlets are kinda funny, they are there to satisfy code for landlords and home owners that don't want to spend the money for an overhead light fixture. One note: no matter which way you go (switched outlet or ceiling mount fixture), if you have multiple exits (or entrances, depending upon how you look at it), each egress has to have a switch control. That rule can make for a lot of 3 way and even 4 way switches depending on the floor plan. Hope that helped!

- Q: I like this Christian girl and I want to seduce her but I heard that they have electrical underwear

- umm first offnothat underwear does not exist. However, could you honestly live with yourself after seducing a girl into having sex with you when you know she will feel absolutely terrible about it afterward? I think you should be really asking yourself that.

- Q: Hi all :)I am looking in to re-wiring a house that has not been re-wired since the 50's. I have been looking at the electrical system where the wires are external to the wall, but in trunking. Does anyone know how much that would cost and if there are any negatives, apart from the aesthetic elements?

- If properly done, it should work fine. This is a peculiar use of the work trunking, which to an electrical engineer means running a plurality of circuits from a single feeder. (It has nothing to do with the conveyance of the wiring.)

- Q: 3 * 1.0 square wire can carry much power of the electrical (one-way) Jiqiu! The Thank you! The More

- Mouse and keyboard with wireless. The other line with a tie under the order on it. It's that simple.

- Q: How to use a multimeter to measure the power line barrier

- (Including PVC, insulation, etc.), insulation sheath (same as the power cable, or control cable, or signal cable, copper wire or aluminum wire), insulation (including PVC insulation, Insulation), applicable objects (such as marine, explosion-proof area) and the cable cross-sectional area and the number of cores. Model knowledge, please refer to encyclopedia: wire ?fr=ala0_1 wire safety carrying capacity,

- Q: For example, i saw a simple electric generator constructed with magnets and fine wire which was spooled to react against the magnets. Is there an advantage to having a spool of fine wire rather than a solid block of copper?

- because its easy to make a cord out of many small wires,instead of one big wire

- Q: 1966 Mustang ignition wire seems to be getting too hot and melts any electrical tape on it.

- You really should identify what you mean by ignition wire. However ordinary PVC electrical tape used (say) on spark plug leads, especially near the plugs or distributor ends, will probably come off, just through the heat around the engine, if nothing else. The heat mainly softens the adhesive on the tape, and it unwinds. If you are talking about the wire from the ignition switch to the coil, it is a resistance (ballast) wire, and normally gets warm. However the same comment re the tape applies if the tape is near the ignition coil end.

- Q: i have 4 dogs and they like to chew things like electrical wires and that could be very harm full to them can anyone tell me a cheep way to get them to stop? i don't want my baby's to get hurt and they are rewinding all my cords!

- Bitter Apple spray! Works very well with our dog and kittens/cats to stop them from chewing on wires, shoes, shoe laces, etc. If you have pets, you should have Bitter Apple spray. If that doesn't work with yours, then get the plastic cord protectors. They are long tubes that you run the wires thru.

Send your message to us

SDI CABLES XLPE 600/1000V Single Core Copper per AS/NZS 5000.1

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches