Roof Sheet Galvanized Treatment Steel Coils

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

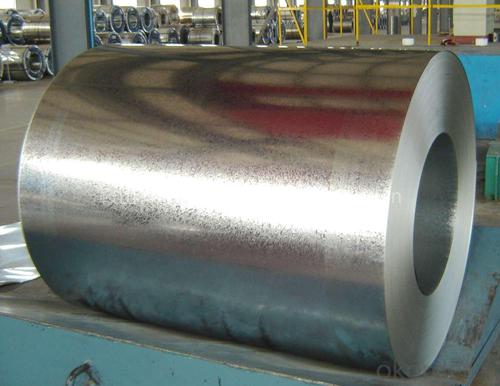

Roof Sheet Galvanized Treatment Steel Coils

Main structure of Roof Sheet Galvanized Treatment Steel Coils

1.Thickness:0.14-2.5mm

2.Width:600-1250mm

3.Grade:SGCC,JISG3302,DX51D,Q235

4.Zinc Coating:60-275g/m2

5.Coil ID:508mm/610mm

6.Coil weight:3-8ton

Specification for Roof Sheet Galvanized Treatment Steel Coils:

| Techinical Standard: | JIS 3302 / ASTM A653 / EN10143 |

| Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

| Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.12-2.5mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating: | galvanized |

| Zinc coating | Z60-275g/m2 |

| Surface treament | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

| Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| ID coil | 508mm or 610mm |

| Coil weight | 3-8 MT per coil |

| Package: | Properly packed for ocean freight exportation in 20'containers |

| Application: | Industrial panels, roofing and siding for painting |

| Price terms | FOB,CFR,CIF |

| Payment terms | T/T L/C |

| delivery time | 25 days after recepit of deposit |

Application of Roof Sheet Galvanized Treatment Steel Coils

Industrial Panels

Building Construction

Roofing and Siding for Painting

Storage Steel Silo

Picture:

- Q: What is the maximum width of galvanized steel strip, please? The galvanized coat is 275, and how long is one coil?

- But this kind of steel coil is not well processed in the market. At the beginning of Wuhan, several processing plants are good at processing, and other processing plants usually process 1850 at most.

- Q: What are the different methods of recoiling steel coils?

- There are several methods used for recoiling steel coils, depending on the specific requirements and characteristics of the material. Some of the common methods include: 1. Slitting: This method involves cutting the steel coil into narrower strips, which can then be recoiled. Slitting is typically done using rotary knives or circular saws, and it allows for precise width control. 2. Rewinding: This method involves unwinding the steel coil and then rewinding it onto a new coil mandrel. It is commonly used when the original coil needs to be resized, or when the coil has become damaged and needs to be reconditioned. 3. Recoiling with a tension control system: In this method, the steel coil is passed through a set of tension control rollers, which apply a controlled amount of tension to the material. This allows for a smooth and even recoiling process, minimizing the risk of coil distortion or damage. 4. Recoiling with a slitter head: This method combines the slitting and recoiling processes into a single operation. A slitter head is used to simultaneously cut the steel coil into narrower strips and rewind them onto separate coils. 5. Recoiling with a looping pit: In this method, the steel coil is fed through a looping pit, which allows for the accumulation of material as the coil is recoiled. This helps to maintain a consistent line speed and tension during the recoiling process. Each of these methods has its own advantages and is suitable for different applications. The choice of recoiling method depends on factors such as the desired coil dimensions, the material's thickness and strength, and the required level of precision and quality.

- Q: What are the quality standards for steel coil manufacturing?

- The quality standards for steel coil manufacturing typically include factors such as dimensional accuracy, surface finish, mechanical properties, chemical composition, and adherence to industry-specific standards set by organizations like ASTM or ISO.

- Q: I saw an amazing flamenco player, however i have a steel string guitar, where he had a nylon stringed one. So i was wndering if its possible to play flamenco songs on the steel string guitar, and where could i find a tab for it? are there tabs for rasegueados?

- Rocket Languages it is a acknowledged leader in online language understanding. With Rocket Language course you will have characteristics like: voice recognition, testing, games, in-built flashcard app and a intriguing design. Rocket Languages is the best option to understand Spanish language.

- Q: I understand that Stainless Steel is a low carbon steel having minimum 10.5% chromium content in it there r 60 different type of stainless steel. Kindly informa) Is this info correct?????b) Which stainless steel can get rusted or can have superficial rust????

- Stainless steel is a generic term for a whole range (there are more than 60 types) of Fe-Cr alloys. They all contain some amount of C and some alloys include a good number of other alloying elements. In almost all cases, the materials have corrosion resistance due the Cr atoms that are in solid solution with the Fe matrix. Under corrosive conditions, the Cr forms a thin tight coherent layer of Cr-oxide. This Cr oxide coating prevents further corrosion so long as it is not chemically or physically removed. If the SS has been subject to mechanical abrasion, the corrosion resistance can sometimes be restored by a light exposure to nitric acid which passivates the surface, restoring the Cr-oxide layer. The carbon content is an important factor in corrosion preformance but so is the heat treatment. Under the wrong conditions and in different environments, all SSs can rust. One of the most common corrosion problems is sensitization which occurs in the heat affect zone (HAZ) around welds. If the C content is high enough and the heat is high enough, the Cr atoms in solid solution form Cr-carbides and are no longer available to form a protective Cr-oxide. The corrosion resistance can be restored by appropriate heat treatment.

- Q: What are the advantages of using steel coils over other materials?

- There are several advantages of using steel coils over other materials. Firstly, steel is highly durable and has a long lifespan, making it ideal for various applications. Secondly, steel coils have excellent strength and can withstand heavy loads and extreme weather conditions. Thirdly, steel is recyclable and environmentally friendly, ensuring sustainability. Additionally, steel coils provide superior corrosion resistance, reducing maintenance costs. Lastly, steel offers versatility in terms of customization, allowing for various shapes, sizes, and thicknesses to meet specific requirements.

- Q: How are steel coils used in the production of scaffolding?

- Steel coils are essential in the production of scaffolding as they serve as a primary raw material for manufacturing various components of scaffolding systems. These coils are typically made from high-quality steel and are used to produce tubes, pipes, and other structural elements that form the framework of scaffolding. The steel coils are first processed through a series of manufacturing operations, such as cutting, shaping, and welding, to transform them into the required dimensions and shapes for scaffolding components. These components can include vertical and horizontal tubes, diagonal braces, and base plates, among others. The tubes and pipes formed from steel coils are the main structural elements used to build the framework of the scaffolding. They are used to create the vertical uprights or standards, as well as the horizontal ledgers and transoms that connect them. These components provide the strength, stability, and load-bearing capacity required for workers to safely access and work at elevated heights. Additionally, steel coils are also used to manufacture diagonal braces, which are crucial for reinforcing the scaffolding structure. These braces are installed diagonally between the vertical standards and provide additional support and stability to prevent the scaffolding from swaying or collapsing. Base plates, another essential component of scaffolding, are also produced from steel coils. These plates are used as a foundation for the scaffolding structure, providing a solid and stable base to distribute the weight and load evenly. They are typically placed at the bottom of each vertical standard to ensure stability and prevent sinking or sliding. In summary, steel coils are a fundamental material used in the production of scaffolding. They are transformed into tubes, pipes, braces, and base plates, which form the framework and provide the necessary strength, stability, and load-bearing capacity required for safe and efficient scaffolding systems.

- Q: What are the common coil handling equipment used in the industry?

- Some common coil handling equipment used in the industry are coil cradles, coil reels, coil straighteners, coil feeders, and coil transfer cars. These tools are essential for safe and efficient handling of coiled materials during various manufacturing processes.

- Q: what is the difference between metal and steel

- well, steel is a type of metal. It's sort of like asking the difference between a bug and an ant, an ant is a bug, but not every bug is an ant. Likewise, steel is metal, but not all metal is steel. Gold is metal, Silver is metal, Iron is metal, Steel is metal.

- Q: i need a company that sells strong steel doors because my neighbors apartment was broken into. I need a strong steel door for the outside of the home, where you first enter. please list places in the US, or in NY.

- Actually, the best doors are fiberglass. Steel doors are not solid steel. The steel is a skin, over framing and insulation. The cheaper doors have thinner steel skins.. That is why they get dented. Go to a real lumber yard. Home Depot and Lowes specialize in low price, not high quality. I use a brand, called Thermatru, that is available in New England. I am sure there are comparable brands. I don't care for Stanley. Stanley makes hammers. They bought a door factory and stick their name on the doors. Good luck.

Send your message to us

Roof Sheet Galvanized Treatment Steel Coils

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords