Hot-Dip Galvanized Steel Roof of High Quality with Different Surface Traetment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

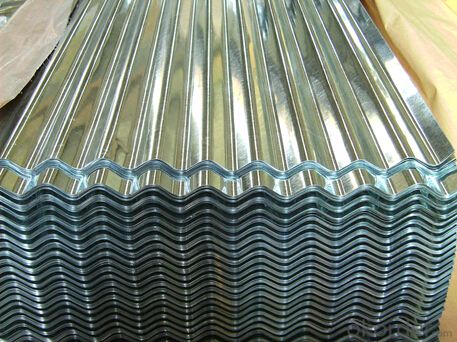

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

What’s the coating composition of Hot-Dip Galvanized Steel Coil?

The coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

- Q: How are steel coils inspected for color consistency using colorimetry?

- Colorimetry is a method used to inspect steel coils for color consistency. This involves quantifying and measuring colors using specialized instruments like spectrophotometers or colorimeters. These instruments measure the hue, saturation, and brightness of the steel coil's color. A colorimeter is typically used to inspect steel coils for color consistency. This device emits light onto the surface of the coil and measures the amount of light reflected back. The reflected light is then analyzed and compared to a known standard color to identify any deviations. To measure color, the colorimeter breaks down the reflected light into different wavelengths and quantifies the intensity of each wavelength. This data is then converted into numerical values that represent the color of the steel coil. These numerical values can be compared to a predefined color standard to determine if the coil's color falls within an acceptable range. To ensure accurate and consistent color measurement, colorimetry relies on standardized color spaces like CIE L*a*b* or CIE RGB. These color spaces define specific ranges of colors. By using these standardized color spaces, colorimeters can provide objective and reliable measurements of color consistency. Color consistency is particularly important for industries like automotive or appliance manufacturing, where the appearance of the final product is crucial. By inspecting the color of steel coils using colorimetry, manufacturers can ensure that the final products have a consistent and visually appealing appearance. In conclusion, colorimetry is an effective method for inspecting steel coils for color consistency. By using specialized instruments and standardized color spaces, manufacturers can accurately measure and compare the color of steel coils to predefined standards, ensuring that the final products meet the desired color specifications.

- Q: I want to know if Diamond is stronger than Steel.

- What Is Stronger Than Diamond

- Q: Can steel coils be coated with anti-graffiti materials?

- Yes, steel coils can be coated with anti-graffiti materials.

- Q: What are the common coil diameter and weight combinations available for steel coils?

- The common coil diameter and weight combinations available for steel coils vary depending on the specific requirements of the industry or application. However, some commonly available coil diameter ranges include 24 inches to 72 inches, while weight combinations can range from 3,000 pounds to 50,000 pounds or more. These dimensions can be further customized based on the needs of the customer and the capabilities of the steel manufacturer.

- Q: Is Stainless steel called that because.....a. Its stains lessORb. Its virtually stainless (it can't stain).Lol do you know the correct answer?????

- Stainless Steel is named that because when compared to untreated steel it is virtually stainless. It is virtually stainless, and harbors very little germs and bacteria. That is why it has been the standard in the food industry for years.

- Q: What exactly is surgical stainless steel made of (metals)? Does it contain nickel? If so, what % does it usually contain? I am deciding between surgical stainless steel piercings or titanium. Both same price and looks. I want to know which one is more hypo-allergenic and generally nickel free.

- um surgical stainless steel? lets try ... stainless steel... herp derp

- Q: How are steel coils measured?

- Steel coils are typically measured by their weight, length, width, and thickness. The weight is usually expressed in tons or kilograms, while the dimensions are measured in inches or millimeters.

- Q: I just got my Daewoo K2 in 5.56 and i know they are tough and reliable but how well will it fair with steel rounds. I know shooting brass is better for any gun but what kind of extra wear and tear would i be looking at with shooting steel. Also what about reloading steel. Is it recomended. I would not even be asking this but steel is far cheaper than brass ammo, and i need to save some money.

- Definitely DO NOT reload steel cases. As far as shooting steel vs brass. Brass will always be better than steel in your gun. Steel is a harder and stronger metal and will wear the firearm quicker than brass.

- Q: Not sure if stainless steel is actually sealable but what's the best way to clean a brushed stainless steel appliance to not get so many finger prints...etc. I have stainless steel wipes that I used on another appliance and they don't work so great.

- Make a paste from Lemon Juice and salt, scrub gently, and then rinse with water. To clean a stainless steel surface, use mild detergent,or baking soda or vinegar diluted in water. Clean, then dry with a soft cloth. Most stainless steel has a grain; if you are using any kind of an abrasive on a stainless surface, always make sure you clean in the direction of the grain. The don'ts are: Don't use bleach. Don't use steel wool unless it is an absolute last resort. Some of the fine particles can lodge in the surface of the stainless and will eventually rust, giving the appearance that the stainless itself is rusting. Don't let the following food items (ketchup, mustard, mayonnaise, lemon juice, vinegar, salt, salad dressings) remain on your stainless surfaces for any length of time. If they sit on the stainless for more than a few minutes, they may bleach it out. You can actually rub out this white area with a very fine Scotchbrite pad. Make sure you are going along the grain lines and not at right angles to them.

- Q: I know that the steel is significantly harder than when air cooled, but why is the quenched steel harder?

- When steel is slowly cooled, lots of carbon diffusion takes place because it is not very soluble in steel at room temperature. The carbon is in solution at high temperatures, and is rejected out of the lattice as it cools. And when this happens, the microstructure will consist of ferrite and pearlite, and the lattice structure will be base centered cubic (bcc). If it is cooled fast enough, then the carbon gets trapped in the interstitial sites of the lattice and distorts it to a body centered tetragonal (same as bcc, but elongated in one direction) This elongation strains the lattice and makes it harder. Also, when cooled fast enough the atoms do not have time to diffuse like they normally would and they shear into place. This forms the hard phase of martensite that is desired of heat treated steel. But then it must be tempered back some because it is too brittle.

Send your message to us

Hot-Dip Galvanized Steel Roof of High Quality with Different Surface Traetment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords