Hot-Dip Galvanized Steel Roof with HIgh Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

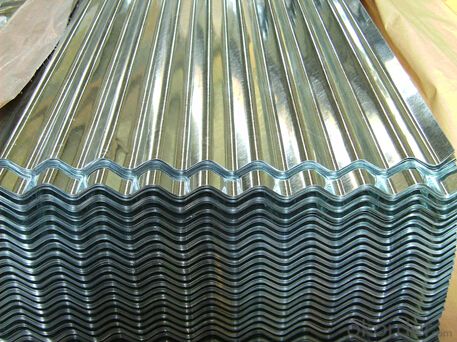

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q: in a lab at school we did heat treatment of steelwhat are the possible phases present in the steel sample in as-received, as-quenched and as-tempered conditions? specifically when is it ferrite, austenite and pearliteis the steel originally in the ferrite phase? then when headed turns into austenite and when quenched martensite is formed and when tempered cermentite is formed...........where is pearlite involved and am i correct about the ferrite?

- hey from what i learned in uni last sem, steel is originally ferrite form at first at room conditions. it will undergo poly morphic transformation to become FCC structure austenite form at 912 degree celcius. under conditions, it can become pearlite (which is a combination of ferrite and cementite) or bainitie( a finer form of pearlite). queching conditions to room temperature will form martensite which is the strongest but brittle steel form. tempered cementite is formed when we quench it and then raise temperatures before sir cooling. hope it helps, pls vote me best answer is i deserve it. thanks

- Q: How are steel coils used in the production of power transmission towers?

- Steel coils are used in the production of power transmission towers as they provide the necessary strength and durability to support the towers and withstand the transmission lines' weight and environmental conditions. The steel coils are shaped and welded into various sections and components, such as the legs, base plates, and cross arms, which are then assembled to create the tower structure. The coils' high tensile strength ensures the towers can withstand the mechanical stresses and loads imposed by the transmission lines, making them a crucial component in the construction of power transmission towers.

- Q: How are steel coils used in the production of HVAC systems?

- Steel coils are used in the production of HVAC systems as they serve as the primary component for heat transfer. These coils are responsible for absorbing heat from the surrounding air and transferring it to cool the interior of a building. Additionally, steel coils are used for the condenser coils in HVAC systems, where they aid in the removal of heat from the refrigerant, allowing for efficient cooling and dehumidification.

- Q: I have one and need info about it??....It has a wooden case around the steel necks.and 20 strings,Twin Tens.

- well, it was made sometime before 1981, because that's when Fender quit making 10 string steel guitars. Without any more information than what you've given me, it could be the Pedal 2000, the PS210, or the Artist Dual 10. Fender made steel guitars from the 1950s through 1981, so it could be from any time in there. I hope you have the pedals with it. The 10-string and dual 10-string models were quite expensive in their day. Unfortunately, if you're thinking of reselling it, you're probably not going to get a lot of money for it unless you find a pedal steel player, and like I said, having all the pedals is very important in that case. Anyway, hope this helped. Good luck. If I were you I'd learn to play it. Pedal steel players are always in demand.

- Q: What are the dimensions of steel coils used in shipbuilding?

- The dimensions of steel coils used in shipbuilding vary depending on the specific requirements of the ship being built. However, common dimensions for steel coils in shipbuilding typically range from 2-15 mm in thickness and 600-2000 mm in width.

- Q: What's the difference between hot rolled coil and hot-rolled carbon thin steel coil?

- The difference between hot rolled primary and hot-rolled carbon thin steel coils is that they include carbon steel rolls and low alloy steel coils.

- Q: How are steel coils protected from extreme weather conditions?

- Steel coils are protected from extreme weather conditions by being stored in covered warehouses or using waterproof covers to prevent direct exposure to rain, snow, and other elements. Additionally, corrosion-resistant coatings are often applied to the surface of the coils to provide an extra layer of protection against moisture and other environmental factors.

- Q: How are defects in steel coils repaired?

- Defects in steel coils are repaired through various methods depending on the type and severity of the defect. Common repair techniques include grinding, welding, soldering, or using heat treatment processes to correct the defects. The specific approach is determined by professionals after assessing the nature of the defect and considering the desired quality and performance standards of the steel coils.

- Q: What are the different methods of forming steel coils into sheets?

- There are several methods of forming steel coils into sheets, including hot rolling, cold rolling, and annealing. Hot rolling involves heating the steel coils and passing them through a series of rollers to reduce their thickness and shape them into sheets. Cold rolling, on the other hand, does not involve heating the coils and instead uses pressure to shape them into sheets, resulting in a smoother and more precise finish. Annealing is a process that involves heating the steel coils to a specific temperature and then slowly cooling them, which helps to relieve stress and improve the material's ductility before it is formed into sheets.

- Q: Can i make holes in iron and steel with somekind of drill bit. All i have is metal drill bits. Mabey like 68 of them but i dont know wich one to use and if they will penetrate.

- That's what drill bits are made for. Those for steel and iron will usually be made of high speed steel. What is important, is the sharpening, and of course, the overall condition of the drill bit. If you need to drill a larger hole, it is helpful to drill a small hole first (pilot drilling), then open it out to size. Never use drill bits you intend to drill iron or steel with to drill such as timber! It will ruin them for steel working.

Send your message to us

Hot-Dip Galvanized Steel Roof with HIgh Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords