Hot-Dip Galvanized Steel Roof with Competitive Price of China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

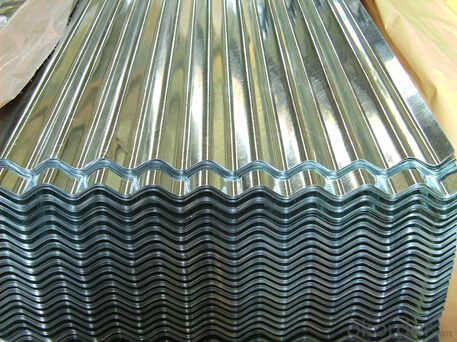

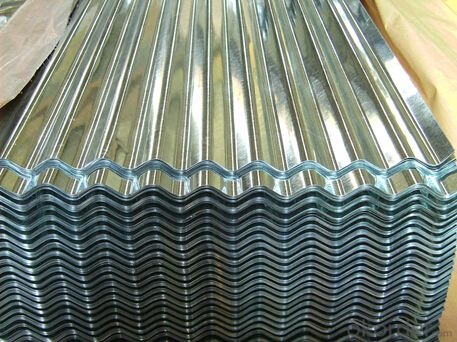

1. Hot-Dip Galvanized Steel Roof Description:

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q: What are the dimensions of steel coils used in the agricultural equipment industry?

- The dimensions of steel coils used in the agricultural equipment industry can vary depending on the specific application and equipment. However, common dimensions for steel coils used in this industry typically range from 0.5 to 3 millimeters in thickness and can have varying widths and lengths, ranging from a few inches to several feet.

- Q: How are steel coils protected during transportation?

- Steel coils are kept safe and free from harm during transport through a range of precautionary measures. One widely used technique involves utilizing top-notch packaging materials like heavy-duty plastic wrap or waterproof paper. These materials form a protective shield against external factors such as moisture, dust, and debris. Moreover, steel coils are typically placed on wooden pallets or skids to elevate them from the ground and prevent direct contact with surfaces that may cause scratches or dents. To provide further protection, the coils are securely fastened to the pallets using strong, corrosion-resistant metal strapping or bands. This ensures that the coils remain in position and do not shift or move during transport, significantly reducing the risk of damage. Additionally, specialized equipment like coil cradles, coil racks, or coil bunks are used to load and secure the steel coils onto flatbed trailers or shipping containers. These devices are specifically designed to firmly hold the coils in place and evenly distribute their weight, preventing any stress or strain during transit. Apart from physical safeguards, steel coils may also undergo various surface treatments before being transported to prevent corrosion. This may involve applying a protective coating or oiling the coils to create a barrier between the steel and the surrounding environment. This process is particularly important when the coils are exposed to adverse weather conditions or long shipping durations, as it helps to prevent rust or other forms of corrosion. In conclusion, a combination of appropriate packaging, secure fastening, and proper loading techniques are employed to ensure the safety of steel coils during transportation. These measures guarantee that the coils arrive at their destination without significant damage.

- Q: pros and cons of stainless steel and carbon steel swords

- Carbon is what samurais added to their swords to make them super strong. The iron ore was cooked in coal for days; the coal adds the carbon. Too much carbon or too little carbon is a bad thing so it was a very important process. I'd have to go with a sword with carbon.

- Q: I am doing an assignment for my materials class, im not asking for the answer but just some help. I have the assignment finished and handed in but the teacher gave it back with one comment, he asked me to explain the grain growth in steel during hydraulic press bending. Im completely stuck, please help. Thanks.

- Well, I can't answer the question for you because, if the press bending is done cold, the grains will not grow (at least not with normal steel alloys). One wonderful thing about metallurgy is that the real answer is it depends because there are all sorts of weird and unexpected things that can happen. Cold work (which is what press bending is unless it is done hot or the amount of deformation is extraordinary high and fast so the metal heats up a lot locally) adds stored energy (strain energy) which provides one of the driving forces for recrystallization. Recrystallization is not a yes/no process, it is a process that happens as a function of time and temperature. Recrysallization of a cold worked structure will refine the grain size if done properly but the final stage of recrystallization is grain growth and you can end up with a larger grain size than you started with. The other thing that can affect grain structure is the deformation itself. There are all sorts of transformations that can happen due to the deformation process (twinning/martensitic is one) but, again, these don't usually qualify as grain growth. It may be that the question was incomplete, maybe the question is how does the press bending affect the final grain size after a subsequent anneal? The metallurgy of steels is fascinating because there are so many different microstructures that can be produced, hundreds (or thousand) different alloys, equilibrium and non-equilibrium phases based on composition and thermo-mechanical processing. Hope this helps

- Q: What are the different types of steel finishes for coil protection?

- There are several types of steel finishes used for coil protection, including galvanized, painted, and coated finishes. Galvanized steel is coated with a layer of zinc to protect against corrosion. Painted steel is coated with a layer of paint for aesthetics and additional protection. Coated finishes can include various types such as epoxy, polyurethane, or polyester, which provide different levels of durability and resistance to corrosion.

- Q: What are the common applications of pre-painted galvanized steel coils?

- Pre-painted galvanized steel coils are extensively utilized across various industries due to their wide range of applications. These coils find common usage in the construction industry for roofing, wall cladding, and structural components. Their coating provides exceptional corrosion resistance and durability, making them suitable for both residential and commercial buildings. The automotive industry also heavily relies on these coils for manufacturing body panels, interior trims, and underbody protection. The pre-painted coating not only enhances the aesthetic appeal of vehicles but also provides protection against rust and corrosion. In the production of home appliances, such as refrigerators, ovens, washing machines, and air conditioners, pre-painted galvanized steel coils are commonly employed. The smooth and durable coating ensures a long-lasting and visually appealing finish for these appliances. The furniture industry also benefits from using pre-painted galvanized steel coils, which are used for manufacturing cabinets, shelves, and other furniture components. The coating on these coils adds a decorative element while offering protection against scratches and wear. In the electrical and electronics industry, pre-painted galvanized steel coils are utilized for manufacturing switchboards, control panels, and enclosures. The pre-painted coating provides insulation and protection against electrical hazards, making them suitable for such applications. In the agricultural sector, these coils are used for manufacturing equipment like grain silos, livestock shelters, and poultry houses. The corrosion-resistant coating ensures the durability and longevity of these agricultural structures. The vibrant and visually appealing colors of pre-painted galvanized steel coils make them a popular choice for signage and advertisement boards. The coated surface provides a smooth and glossy finish that enhances the visibility and attractiveness of the signage. To summarize, pre-painted galvanized steel coils offer excellent corrosion resistance, durability, and aesthetic appeal, making them suitable for a wide range of industries and applications, including construction, automotive, appliances, furniture, electrical and electronics, agricultural equipment, and signage and advertisement.

- Q: What are the dimensions of steel coils used in the building materials industry?

- The specific application and requirements determine the varying dimensions of steel coils in the building materials industry. Typically, steel coils in this industry have a thickness ranging from 0.5mm to 3mm and a width ranging from 600mm to 1500mm. The length of the coil can vary based on the manufacturer and customer specifications. It is important to note that the weight of the coil also varies, with typical weights ranging from a few hundred kilograms to several tonnes, depending on the size and thickness of the coil. Ultimately, the dimensions of steel coils in the building materials industry are determined by the specific needs and specifications of the intended construction projects.

- Q: In what ways can steel fail in use of buildings ad what can be done to prevent it?

- First let us see what steel is made from. PIG IRON, which is put into a blast furnace with other things to get the impurities out. the very high grated of steed include TUNGSTEN CARBIDE STEEL, which is used to make tooling. down to lower grades of steel to make other things. the stronger the steel that is required the less impurities that are in it. different steels are treated with different elements depending on what the steel is going to be used for, So if steel is Incorporated into a building and say the building caught fire enough heat could be produced to actually soften the steel and result in failure. hope this helps. Dr Knowitall.

- Q: Moravia’s coal and steel industries face challenges because they _____. a.do not run efficientlyb.have run out of resourcesc.have a declining work forced.have not privatized

- do not run efficiently is the correct answer

- Q: How are steel coils packaged for shipping?

- Steel coils are typically packaged for shipping by being tightly wound and secured with steel strapping or bands. They are then placed onto pallets or into crates to protect them during transportation. Additionally, wooden or metal dunnage is often used to separate and stabilize the coils, ensuring they remain intact and in proper condition throughout the shipping process.

Send your message to us

Hot-Dip Galvanized Steel Roof with Competitive Price of China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords