All Categories

- - Steel Wire Rod

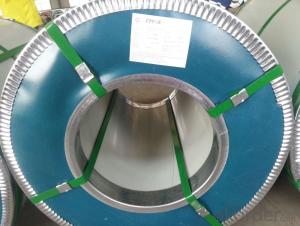

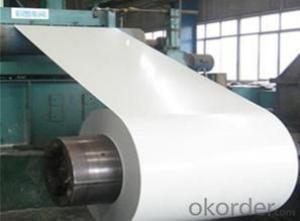

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

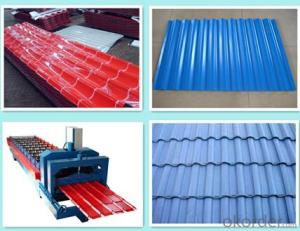

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures are in place to prevent coil flatness issues when manufacturing metal office equipment, such as filing cabinets and desks?

There are several measures in place to prevent coil flatness issues when manufacturing metal office equipment. Firstly, manufacturers carefully select high-quality metal coils that have been properly annealed and processed to ensure consistent flatness. Additionally, advanced leveling machines are utilized during the manufacturing process to eliminate any residual coil stress and accurately flatten the metal sheets. Strict quality control procedures are followed to detect and reject any sheets that do not meet the required flatness specifications. Regular maintenance and calibration of machinery are also conducted to ensure optimal performance and minimize the risk of coil flatness issues. Overall, these measures help ensure that metal office equipment, such as filing cabinets and desks, are manufactured with the desired flatness and structural integrity.

What is the significance of coil gauge variation in the fabrication of metal signage?

The coil gauge variation in the fabrication of metal signage is significant because it determines the thickness and durability of the metal used. A lower gauge number indicates a thicker and more robust metal, making it suitable for larger or outdoor signs that require high durability. On the other hand, a higher gauge number indicates a thinner and more flexible metal, which is better suited for smaller or indoor signs. By considering coil gauge variation, manufacturers can ensure they use the appropriate metal thickness for different signage applications, resulting in effective and long-lasting products.

How are steel coils inspected for oil residue?

Steel coils are inspected for oil residue through a visual examination, where trained inspectors carefully observe the surface of the coils for any signs of oil stains or residue. Additionally, certain methods such as wipe tests or solvent extraction may be employed to detect and quantify the amount of oil present on the coils.

Wholesale Steel Coils from supplier in Syria

We understand the unique requirements and challenges of the Syrian market and can offer tailored solutions to meet your specific needs. Whether you are looking for hot-rolled coils, cold-rolled coils, galvanized coils, or any other type of steel coils, we have a wide range of options available.

Our team of experts is dedicated to providing exceptional customer service and support. We can assist you with product selection, pricing, and logistics, ensuring a smooth and efficient procurement process. Our strong relationships with reliable suppliers and manufacturers allow us to deliver high-quality products at competitive prices.

Furthermore, we are committed to providing technical support to help you make informed decisions. Our knowledgeable team can offer guidance on steel grades, specifications, and applications, ensuring that you choose the right steel coils for your projects.

By choosing us as your supplier of steel coils in Syria, you can benefit from our global presence and extensive resources. As a subsidiary of CNBM, we have access to a vast network of suppliers, ensuring a steady supply of high-quality products.

Contact us today for all your steel coils requirements in Syria. We are here to provide you with the best solutions and support for your projects.

Our team of experts is dedicated to providing exceptional customer service and support. We can assist you with product selection, pricing, and logistics, ensuring a smooth and efficient procurement process. Our strong relationships with reliable suppliers and manufacturers allow us to deliver high-quality products at competitive prices.

Furthermore, we are committed to providing technical support to help you make informed decisions. Our knowledgeable team can offer guidance on steel grades, specifications, and applications, ensuring that you choose the right steel coils for your projects.

By choosing us as your supplier of steel coils in Syria, you can benefit from our global presence and extensive resources. As a subsidiary of CNBM, we have access to a vast network of suppliers, ensuring a steady supply of high-quality products.

Contact us today for all your steel coils requirements in Syria. We are here to provide you with the best solutions and support for your projects.